您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

PyroGenesis Canada Inc. has recently publicised its latest contracts with Aluminerie Alouette worth $2.7 million. These contracts aim to further advance PyroGenesis' spent pot lining valorisation technology and develop a new valorisation solution for excess electrolytic baths.

The contracts are expected to address primary aluminium production process residue streams. The project funding will be contributed by both Aluminerie Alouette and the Centre québécois de recherche et de développement de l’aluminium (“CQRDA”) and will be administered by the provincial government’s Ministry of the Economy, Innovation, and Energy for Quebec’s aluminum industry. We can anticipate that these efforts will pave the way for a more sustainable and efficient aluminium production process in the future.

The CEO of PyroGenesis, Mr P. Peter Pascali, pointed out: "We are very proud to be partnering, once again, with Aluminerie Alouette, a company renowned for its environmentally friendly practices and which operates the largest aluminium smelter in the Americas."

"PyroGenesis' technology and engineering capabilities will help re-use residues from aluminium production, including spent pot lining and electrolytic bath, thus helping Aluminerie Alouette advance its decarbonisation strategy. These are the types of projects that underscore PyroGenesis' strategy to position its processes to enable sustainable and environmentally responsible practices within the aluminium industry," Mr Pascali seemed quite optimistic.

Aluminium is produced using the Hall-Héroult reduction process, which involves electrolytic cells called "pots". The pots contain alumina and a solvent, with a high amperage electric current causing chemical reactions that decompose alumina into molten aluminium and carbon dioxide. The lining of the pots typically lasts 5 years before needing replacement due to contamination, with the decommissioned pots leaving behind hazardous "Spent Pot Lining" residue.

The extraction of valuable materials from SPL, while hazardous, can be safely achieved through proper handling. A recent announcement highlighted a project aimed at developing an eco-friendly method to extract these materials, which could have a significant impact on the aluminium industry in Quebec and globally. It is worth noting that the global collection of SPL is approximately 1.5 million tonnes annually, underscoring the importance of responsible handling. PyroGenesis' innovative approach represents a positive step towards addressing these concerns, and we look forward to observing its success.

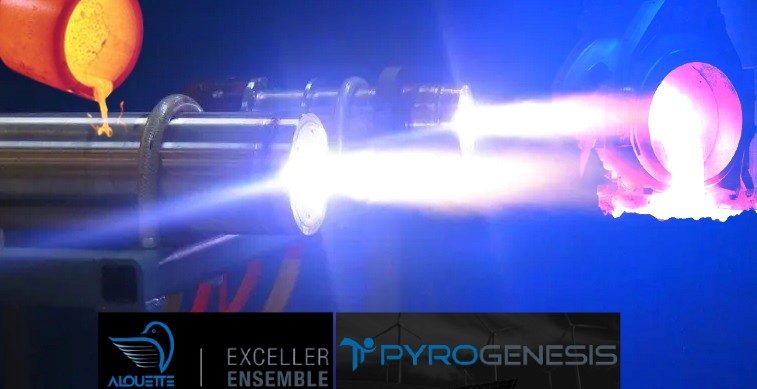

PyroGenesis' innovative solution for recycling SPL is a game-changer. By using their plasma arc thermal treatment plant, they're able to transform carbonaceous and refractory materials into synthesis gas and aluminium fluoride, which can be put to good use by Aluminerie Alouette in their production processes. This method is not only more cost-effective but also reduces or eliminates the expenses associated with SPL management and processing. It's a win-win situation for everyone involved.

Another project has been announced today, and it follows a similar approach to the first project. The project aims to utilise an excess electrolytic bath, also known as a "pure bath" or "bath", which is produced during normal operation. However, we must acknowledge that this residue is considered hazardous due to its high fluorine content. The project's primary goal is to process the residue in a plasma arc thermal treatment plant and produce aluminium fluoride, which is a shared element with the first project.

Pyrogenesis is currently performing R&D on a thermal plasma furnace and gas purification system, along with gas conversion experiments. Its plans include testing and designing pre-commercial and full industrial-scale systems with Aluminerie Alouette, a large aluminium producer. They prioritise sustainability and innovation.

Responses