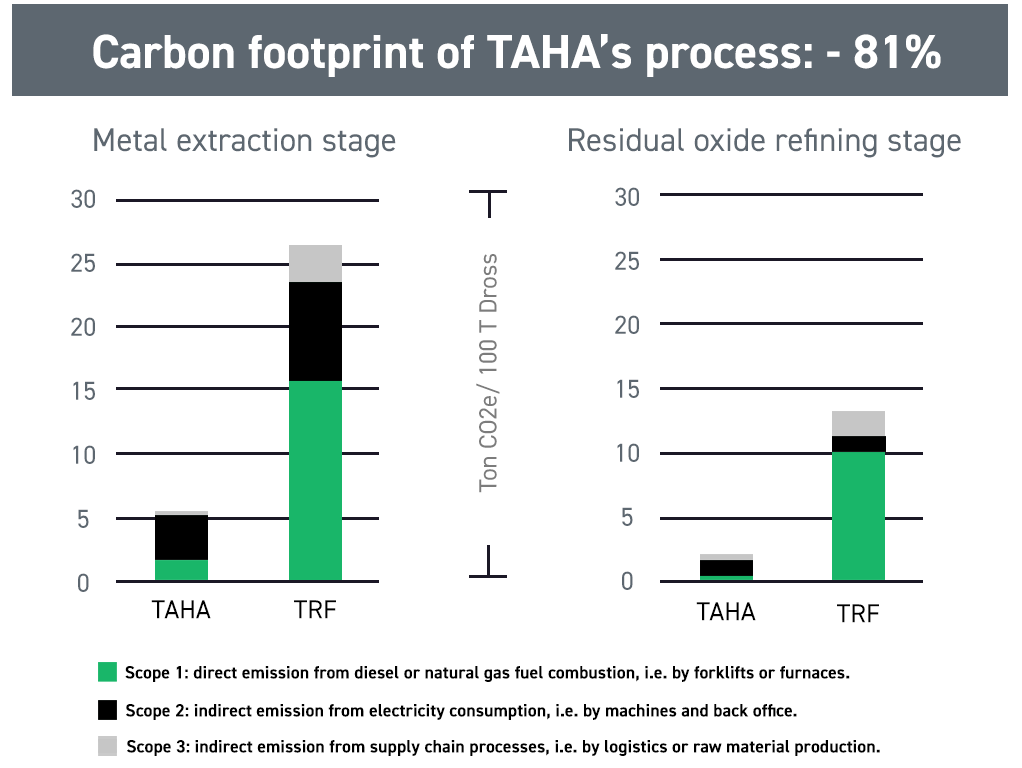

Aluminium dross processing technology by TAHA demonstrates 81% less GHG in comparison to the TRF method

TAHA, a multi-discipline solutions provider offering innovative, environmentally-friendly, and cost-effective services, equipment and products to the aluminium and steel industry worldwide. Environmental considerations are becoming increasingly pertinent in “green” aluminium production making reducing or eliminating waste ever more so important. TAHA’s aluminium dross process is a radical innovation in its industry whose process consumes less energy and produces no toxic salt cake. This enables organizations to save valuable resources and reduce costs.

TAHA anticipated their operations to provide a dross processing solution with a lower carbon footprint than the conventional TRF (Tilting Rotary Furnace) process. Fully convinced internally that the TAHA process had a considerably reduced carbon footprint than the alternative process, TAHA recently requested Ernst and Young Netherlands to analyse and compare its operational carbon footprint to the conventional TRF process to evaluate and validate differences between both processes in an objective and conservative manner.

In order to provide detailed insights into the carbon footprint compared to the benchmark, TAHA, KMF and EY in collaboration with the Austrian Montanuniversität Leoben (in the renowned “ShanghaiRanking” in the category “Global Ranking of Academic Subjects”, Montanuniversität was ranked 15th in the field of Metallurgical Engineering), analysed the carbon footprint of TAHA’s aluminium dross process utilizing a process life cycle assessment. The commissioned study was completed in February 2021, and the analysis demonstrates that the carbon footprint of TAHA’s method vastly outperforms the conventional TRF method, showing more than 81% less GHG emissions.

This comparison is intended to give further insights into the differences between the carbon footprint from TAHA’s approach and the conventional TRF aluminium dross processing method and enables TAHA to further identify the carbon footprint hotspots in their process and to take focused actions on further limiting emissions.

The carbon footprint calculation has followed the methodology stipulated by the Greenhouse Gas Protocol (GGP), which is globally appraised for its maturity in approaching carbon accounting. Consequentially, this entails that the results are structured into three scopes and that the presented greenhouse gas (GHG) emissions include all six gases as included in the Kyoto Protocol.

This news is also available on our App 'AlCircle News' Android | iOS