Shandong Hongcan leads the way with innovative "One Mould Four Outputs" manufacturing solution

Shandong Hongcan Material Technology Co., Ltd., the subsidiary of China Hongqiao Group, one of the world's largest aluminium producers covering the entire aluminium industry chain, stands at the forefront of innovation and efficiency in China's manufacturing sector. This pioneering company is revolutionising the production of automotive aluminium alloy structural parts, driving progress with remarkable strides.

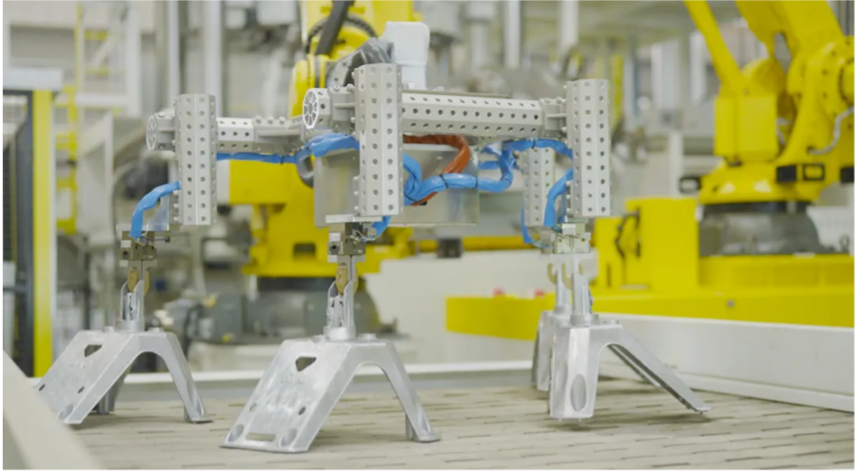

Shandong Hongcan Material Technology has recently achieved a remarkable feat by introducing China's pioneering "One Mould Four Outputs" technology. This revolutionary advancement enables a single mould to produce four automotive parts concurrently, marking a significant leap in production efficiency and cost reduction within the manufacturing realm. Through the seamless integration of this cutting-edge technique, the automotive manufacturing landscape in China stands poised for a transformative evolution.

Confronted with formidable technical hurdles such as precision forming, stringent internal quality control, and deformation prevention in the 'One Mould, Four Outputs' process, the Shandong Hongcan team has showcased unparalleled expertise. Their meticulous efforts have led to flawless product formation and successful navigation through rigorous third-party assessments. These assessments encompassed a spectrum of critical evaluations, including mechanical performance, resistance to salt spray corrosion, and validation of collision safety measures.

China Hongqiao Group stated, "Our breakthrough mould temperature control technology, precise nozzle system, top-notch aluminium liquid, and meticulous tooling design, coupled with the expertise of our seasoned engineers, have facilitated this achievement. With a total investment of RMB 1.7 billion, our cutting-edge Shandong Hongcan Material Technology facility is now equipped with state-of-the-art machinery, including the world-renowned Bühler die-casting machines pivotal for the 'One Mould Four Outputs' method."

"This innovative approach has revolutionised our production, slashing manufacturing times from over 120 minutes to a mere 140 seconds. Moreover, it has led to a remarkable 10 per cent reduction in energy consumption per tonne of product, pushing our material recycling rate to an impressive 95 per cent."

Utilising aluminium sourced from upstream channels within the China Hongqiao Group, the organisation pioneered the nation's inaugural "liquid aluminium-die casting-automobile manufacturing-recycling" green industrial chain. The primary offerings encompass integrated die-cast aluminium alloy structural components, such as shock absorber towers, longitudinal beams, rear bottom plates, battery casings, and gearbox enclosures. Boasting an annual capacity of 3 million precision aluminium alloy structural parts spanning eight distinct categories, the Group's subsidiary is poised to serve as a critical supplier to prominent automotive manufacturers, including Tesla, BYD, CATL, Chery Automobile, and BAIC Group.

"Shandong Hongcan Material Technology's groundbreaking achievement exemplifies China Hongqiao's ongoing commitment to innovation, sustainability, and the advancement of the manufacturing industry in China. Through continuous technological innovation and strategic investment, we are driving progress, promoting sustainable development, and shaping the future of manufacturing in China and beyond", China Hongqiao Group concluded.

This news is also available on our App 'AlCircle News' Android | iOS