您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

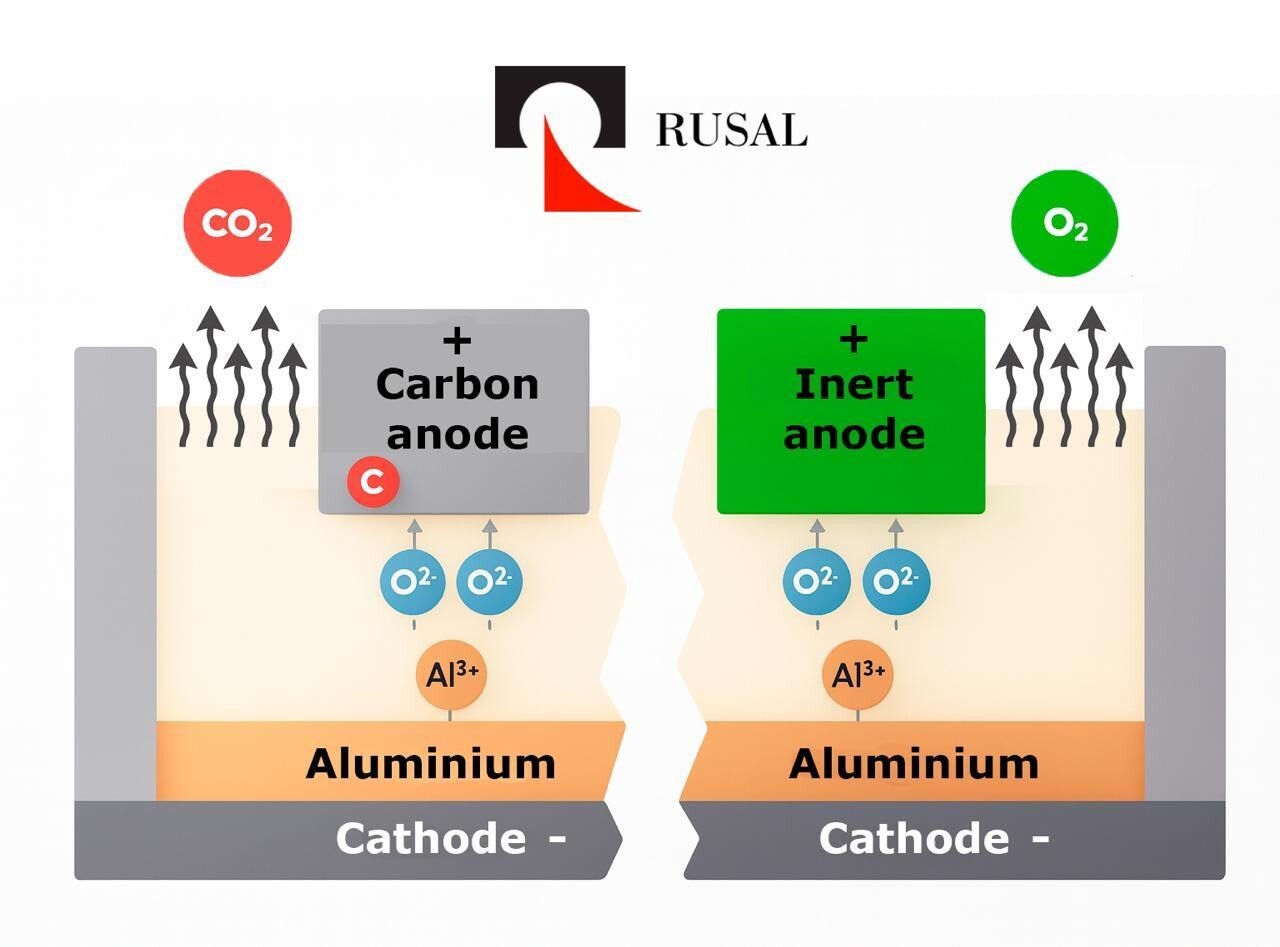

RUSAL, one of the world’s largest aluminium producers has achieved stable production of Grade A7 aluminium using inert anode technology. This milestone marks a critical step toward the industrial implementation of this breakthrough process. Unlike conventional methods, inert anode electrolysis emits oxygen instead of carbon dioxide and significantly reduces unwanted impurities in the aluminium.

Following extensive and successful trials, RUSAL has confirmed the operational stability of its proprietary industrial-scale inert anode technology. This process enables the consistent production of commercial-grade A7 aluminium (international equivalent: P1020). Stability at this level is the key requirement for transitioning from pilot testing to full-scale industrial deployment of a technology that eliminates the need for carbon anodes and sets new environmental benchmarks for the aluminium industry.

RUSAL is now moving closer to full-scale implementation of inert anodes across its smelters. The demonstrated process stability confirms the technology’s industrial readiness and represents a significant step toward sustainable aluminium production in line with global ESG principles.

Carbon anodes have been a mainstay of the aluminium industry since its inception in the late 19th century. Replacing them with inert anodes allows for the substitution of several tons of greenhouse gas emissions per ton of aluminium with 0.9 tonnes of pure oxygen during electrolysis, while also drastically reducing impurities—such as heavy metals and silicon—that typically originate from carbon anodes.

Also read: Rusal posts $87M loss in H1 2025 despite 32% revenue surge — what went wrong?

“Inert anode technology represents a leap forward in aluminium electrolysis. We have achieved stable operation across a group of electrolysers and are now preparing for scale-up. This innovation—designed from the outset as a next-generation solution—reinforces our technological leadership,” Alexander Gusev, Head of RUSAL’s Inert Anode Electrolyser Project, said.

Aluminium produced using inert anodes demonstrates exceptional purity, giving it a strong competitive advantage. Its superior properties make it ideal for both foundry alloys—ensuring ductility and casting reliability—and electrical applications, from wire rod to foil. The minimal content of heavy metals and silicon reduces electrical resistivity and enhances the quality of finished products.

RUSAL is currently evaluating industrial deployment scenarios and identifying optimal applications for this low-carbon, high-purity aluminium in sectors that demand the strictest standards for both environmental impact and metal quality.

Note: This article has been issued by RUSAL and has been published by AL Circle with its original information without any modifications or edits to the core subject/data.

Responses