您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

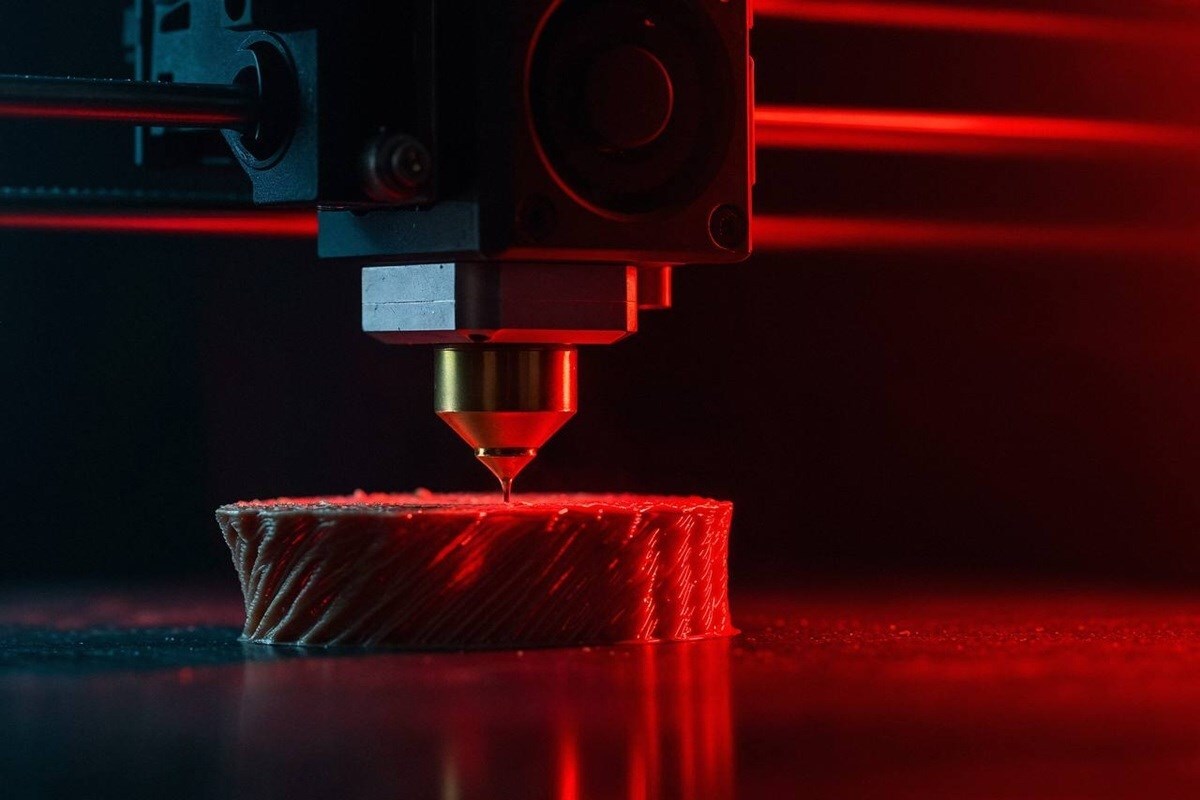

RUSAL, a leading global aluminium producer, has unveiled a breakthrough in a composite material for 3D printing. The new metal matrix composite designated RS-770K offers a tensile strength 30 per cent greater than that of the strongest aluminium powder alloys, opening new frontiers for additive manufacturing in high-performance applications.

{alcircleadd}To know more about the global primary aluminium industry 2026 outlook, book the report “Global ALuminium Industry Outlook 2026".

Developed in-house, the RS-770K composite combines an aluminium matrix with ceramic particles, achieving a remarkable tensile strength of 615 Megapascals (MPa). This represents a 30 per cent increase over the RS-553 alloy- the strongest aluminium powder alloy in RUSAL's portfolio, which contains a high percentage of the rare-earth metal scandium.

Read More: Kinesis bets on aluminium as RTD aims to rival carbon endurance bikes

The material's unique properties bridge a critical gap in additive manufacturing in retaining the signature lightness of aluminium, and its strength characteristics mark a significant step toward those of steel and titanium alloys. Aluminium is one of the lightest structural metals, approximately three times lighter than steel and one-and-a-half times lighter than titanium.

RS-770K is the first 3D-printing composite developed by RUSAL's R&D Department. Previously, the department created more than ten aluminium alloys for additive manufacturing, all designed to enhance key properties—such as strength, heat resistance, and yield strength—beyond those of the industry-standard AlSi10Mg powder alloy.

Must read: Key industry individuals share their thoughts on the trending topics

Note: This article has been issued by RUSAL and has been published by AL Circle with its original information without any modifications or edits to the core subject/data.

Responses