您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

In the age of Industry 4.0, "visibility" goes far beyond what meets the eye. Smart factories are now leveraging sensors, IoT, and data analysis to monitor and optimize every aspect of their operations, including the precise management of the invisible industrial gases that are crucial to key processes. From small workshops to large-scale manufacturers, businesses are adopting these technologies to build smarter, more efficient workflows.

Explore- Most accurate data to drive business decisions with 50+ reports across the value chain

Precise control of the delivery of industrial gases is essential for many processes, demanding continuous oversight to maintain efficiency and safety. Real-time monitoring is vital to ensure industrial gases remain within specified parameters, supporting smooth and reliable operations. Without proper monitoring, companies risk equipment failures, safety hazards, diminished product quality, increased waste, and costly disruptions to productivity.

Smart, connected systems are revolutionizing this process by providing continuous, real-time updates. These systems utilize visual indicators on devices and transmit signals to control systems for remote monitoring and management.

They instantly detect deviations in key factors like pressure, flow rates, mixture ratios, temperature, and gas purity, triggering alarms to halt operations before minor issues escalate into major problems. Early warnings allow operators to address potential concerns proactively, enabling smarter, condition-based preventive maintenance.

Beyond their operational advantages, these advanced systems also contribute to lower gas consumption, reduced defects and waste, and enhanced workplace safety. They promote environmental sustainability while driving operational excellence.

Some advanced valves go even further, offering not only visual indicators and data transmission but also remote control capabilities, whether operated by personnel or automated systems. For instance, automated electric mixing valves provide several advantages. They enable precise adjustments, delivering far greater accuracy and control compared to manual operation. This ensures a reliable and consistent gas mixture, which is essential for maintaining uniformity in experiments or production processes. The electronic controls also make it easy to reproduce specific gas mixtures, ensuring consistency across different applications.

This precision and flexibility are especially valuable in production environments that demand adaptability, such as laser cutting. Switching between different cutting conditions—such as the quality of the cut, the material's thickness, and the speed at which the laser moves. Automated mixing valves simplify these adjustments, enhancing both efficiency and performance.

Intelligent gas valves and mixers also provide detailed data for analysis, enabling businesses to uncover insights that drive continuous improvement. By tracking trends, addressing quality concerns, ensuring traceability, and identifying inefficiencies, businesses can optimize their operations and make informed, data-driven decisions. This is especially critical in industries where precise gas control is essential to maximize efficiency and ensure consistent product quality.

Industrial gases play a vital role across many industries. Processes like laser cutting, and arc welding depend on precise gas delivery to achieve consistent, high-quality results.

Accuracy is everything. Proper management of gas pressure, flow rates, and mixtures—such as argon (Ar), helium (He) , nitrogen (N₂), carbon dioxide (CO₂), and oxygen (O₂)—can significantly impact success. For example, precise shielding gas dosing and delivery improves gas metal arc welding (GMAW) efficiency, boosting welding speed, extending duty cycles, and reducing cleanup time.

Consistently delivering precise amounts of shielding gas is crucial for achieving efficiency and reducing costs for GMAW. The proper gas mixture can boost welding speed, increase duty cycles, and minimize cleanup time.

Key factors like heat transfer, oxidizing potential, and metal transfer characteristics determine welding performance. For example, high-thermal-conductivity gases create hotter, more fluid weld puddles, while high-oxidizing gases enhance weld coalescence. Argon-based blends allow for spray transfer, achieving higher deposition efficiency and travel speeds compared to carbon dioxide. Using argon blends reduces spatter, preventing nozzle blockages and wire feed issues common with carbon dioxide shielding. This results in longer welding cycles and less downtime for cleanup.

WITT Gas mixers supply mixed gases conforming to AWS 5.32 for weld shield gases per the AWS code or ISO 14175 gas mixtures for fusion welding and allied processes. Each mixer is supplied with a factory test certificate, plus the mix ratio can be audited in real time or saved on a local PC or integrated network.

Don't miss out- Buyers are looking for your products on our B2B platform

The advancements in smart, connected valves have transformed industrial gas applications, providing levels of precision and control. These state-of-the-art valves are equipped with sensors and IoT-enabled technologies, allowing real-time monitoring and remote management of gas flow and pressure. By integrating these sophisticated systems, industries can enhance safety, optimize efficiency, and reduce operational costs. Such innovations are paving the way for smarter, more sustainable welding and gas handling solutions.

Dome pressure regulators are preferred to spring-loaded types for most manufacturing applications due to their exceptional gas pressure stability. Instead of relying on steel springs, dome regulators use a gas cushion to maintain constant working pressure, even during inlet pressure fluctuations or varying gas withdrawal rates. This ensures greater process, safety and stability, making them ideal for high-performance applications.

WITT has advanced dome pressure regulator technology by integrating the pilot pressure and regulator into a single, ready-to-use valve. This reduces installation and maintenance costs while allowing for operation with an electrical proportional valve, enabling external control system integration.

WITT’s smart dome pressure regulators take performance further by incorporating sensors to measure gas pressure and temperature at both inlet and outlet. They calculate real-time gas flow, transmitting precise data

for process optimisation, safety, and transparency. These innovations ensure consistent pressure control, even with minimal pressure differences, making them perfect for demanding industrial processes.

Additional safety and performance can be achieved with WITT’s COLDSTOP SMART. Renowned for best-in-class accuracy and smart communication features, WITT’s dome-loaded pressure regulator just got smarter: COLDSTOP SMART now detects critically low temperatures and stops gas flow to safeguard piping. Specifically designed to protect downstream equipment and piping from brittle fractures, this innovative solution establishes a new benchmark for safety, cost efficiency, and remote monitoring in cryogenic systems.

Maximum Protection for Cryogenic Systems

COLDSTOP SMART addresses a critical challenge in cryogenic gas applications—minimising the risk of excessively low temperatures in the gas pipework downstream of the vaporiser, which can cause brittle fractures in mild and carbon steel equipment. Unlike traditional mechanical temperature switches that rely on bi-metallic strips and offer imprecise, unreliable performance, COLDSTOP SMART features integrated technology consisting of the WITT smart dome-loaded pressure regulator, solenoid valves and control unit.

This solution stops the gas flow immediately if the temperature falls below a defined setpoint value and restarts as soon as the previously configured setpoint state is reached again. This ensures maximum protection against brittle fractures, enabling companies to meet the relevant EIGA, CGA, and AIGA standards for cryogenic vaporisation systems.

Improved Safety, Cost Efficiency, and Remote Monitoring

COLDSTOP SMART offers several key benefits for users. It enhances safety by providing best-in-class outlet pressure control accuracy and ensures accurate automatic flow stoppage at critical temperature thresholds. This significantly reduces the risk of equipment failure and enhances overall operational safety. Additionally, it helps reduce costs by preventing damage to expensive equipment and avoiding unplanned shutdowns, which in turn lowers maintenance costs and extends the lifespan of piping and systems.

The smart regulator is ideal for cryogenic tank telemetry, with its support for remote monitoring and custom configuration. It transmits real-time status data—including flow, pressure, and temperature—via 4-20 mA signals and RS-485 communication. The system can be custom-configured to trigger alarms and initiate corrective actions, such as activating additional vaporiser capacity, providing users with greater control and visibility over their operations.

Read More: A quiet revolution: ValCUN’s REMUS 1.0 pushes aluminium AM towards full-scale industry use

Compliance with Industry Standards

COLDSTOP SMART not only complies with the EIGA/CGA/AIGA harmonised standards for preventing brittle in cryogenic systems but is also CE-marked.

“Our dome-loaded pressure regulator, already the most accurate and capable of ‘talking’ through real-time data, now takes safety to the next level by knowing when to stop gas flow if temperatures drop too low,” said Andrew Smart, WITT Sales Director for Gas Safety Equipment.

Example: Smart Safety Pressure Relief Valves

Safety relief valves prevent excessive pressure and thus protect plants, machines, production processes and, finally, human lives. Safety relief valves are often the last line of defense against explosion – and such an explosion could be fatal. Other common names for safety relief valves are pressure relief valve, safety valve, or blow-off valve.

If there is a defined overpressure, the safety relief valve opens. The pressure is reduced by blowing off the gas. As soon as the pressure drops below the danger threshold, the safety relief valve closes directly. This is done so safely and reliably that the opening of the valve may go completely unnoticed.

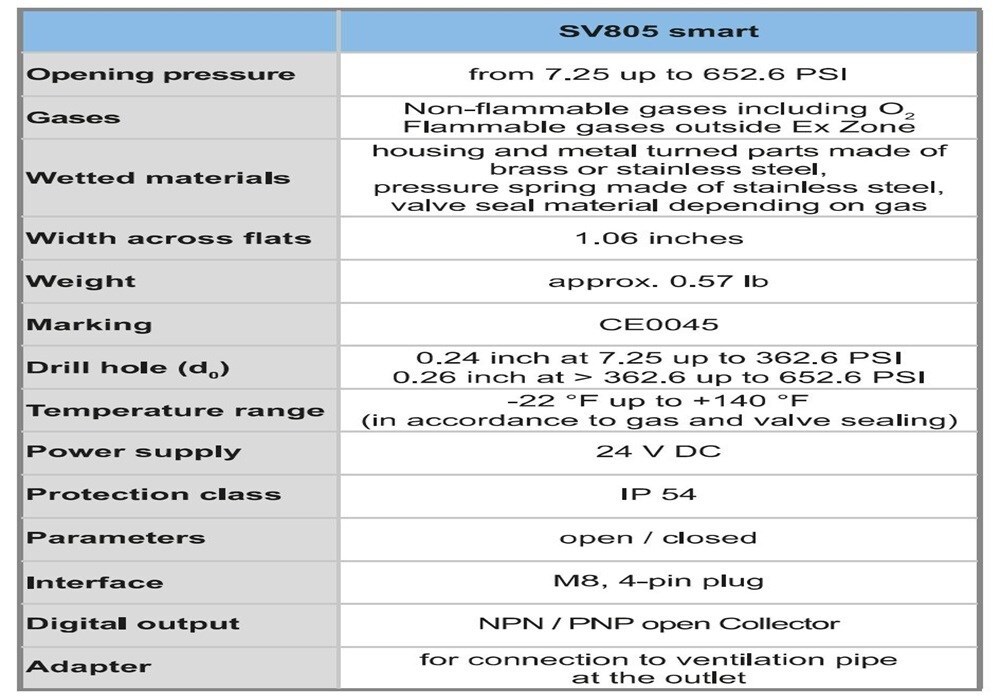

Witt has transformed traditional safety relief valves into intelligent, connected devices by integrating advanced sensor technology. These smart valves continuously monitor their status (open/closed, pressure) and transmit real-time data via optical and digital signals. This innovation allows plant operators to remotely monitor valve performance, detect potential issues early, and respond quickly to critical situations. Not only can the SMART safety relief valves monitor when they are engaged for release of excess pressure, but they can also provide data on the pressure the valve re-seats. This provides valuable information as to the possible safety of the gas process.

A third example of how automated, intelligent, and connected industrial gas monitoring and control technology is driving modernisation and digitisation of manufacturing processes through advanced gas mixing systems.

At the forefront of this innovation are WITT’s Smart Gas Mixers with electronic control, specifically designed for seamless integration into networked production environments. These mixers utilise OPC-UA (Open Platform Communication - Unified Architecture), a globally recognised communication standard supported by over 600 manufacturers. Adoption of this open protocol ensures compatibility across diverse systems, seamlessly integrating gas into modern, connected factories aiming for efficiency and technological cohesion.

To complement its advanced hardware, WITT provides WEBVISIO, a software solution designed for comprehensive monitoring and management of gas installations. It supports two-way communication, enabling users to not only track data but also send commands, such as adjusting limit values. This functionality helps improve efficiency, maintain transparency, and ensure precise control in gas management systems.

Must read: Key industry individuals share their thoughts on the trending topics

Protect Operations with Advanced Gas Monitoring and Control

Investing in cutting-edge industrial gas monitoring and control systems isn’t just smart, it’s strategic. These solutions deliver a strong return on investment by optimizing production processes and safeguarding expensive equipment, such as laser cutting machines, from potential damage caused by gas inconsistencies.

Additionally, they represent a modest cost compared to the value of the equipment they protect and optimize, ensuring you get the most out of your investment.

Think of these systems as the gas equivalent of electrical safety devices like surge protectors or uninterruptible power supplies. Just as no one would risk sensitive machinery without electrical protection, advanced gas control systems have become essential for ensuring the stability, efficiency, and longevity of gas-dependent operations. In today’s manufacturing environment, these tools are no longer optional; they’re indispensable.

Note: This article has been issued by WITT Gas and has been published by AL Circle with its original information without any modifications or edits to the core subject/data.

Responses