您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

For those who are familiar with alumina production by the Bayer Process it is evident that that the Cost of Production (COP) largely depends on the Available alumina (A.Al) and Reactive silica (R.Si) content of the particular bauxite. The caustic consumption, which is mainly dependent on A.Al and R.Si; constitutes the second largest cost item after the cost of bauxite in the Bayer process.

Image for representational purpose

Image for representational purpose

In India there are large lateritic bauxite resources with medium available alumina (trihydrated alumina, THA) and medium to high Reactive SiO2 content. With the deteriorating bauxite quality, refineries are struggling to keep the alumina production cost at the low level.

The Updated Improved Low Temperature Digestion (ILTD) Process as a novel way to increase the economic and environmental effectiveness of the alumina production is summarised in this paper.

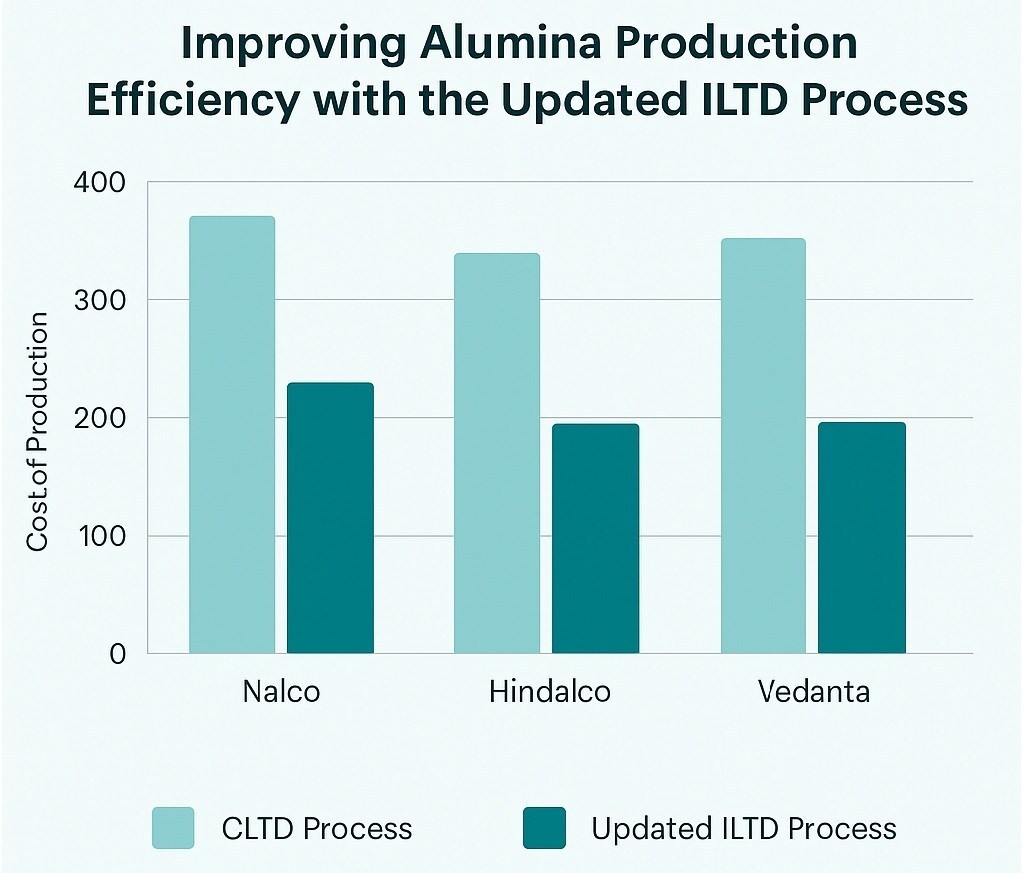

The approximate qualities of bauxite feedstocks, the production levels, and estimated unit costs were used for three alumina refineries located in the Eastern part of India. The Material and Energy consumptions, the amount and composition of bauxite residues, the same for the dicalcium-silicate (C2S) by-products were calculated and used to present the improvement in the COP of the Updated ILTD Process compared with the Conventional Low Temperature Digestion (CLTD). The coverage, i.e. difference of the Selling Price and the Cost of Production could be increased by 30, 64 and 77 per cent, respectively by the Updated ILTD Process. The Investment costs for the upgrade and the approximate Payback periods are estimated for each of the alumina refineries. For the three alumina refineries the Payback periods were found to be 1.9, 2.5 and 3 years, respectively, which are deemed to be good returns of investments. The aluminous laterites that are reasonably considered to be sub-economic materials for the Conventional Bayer Process are suitable for their viable processing with the Updated ILTD Process. In this case the Payback period was found to be low (1.3 years) „Bánvölgyi, G. (2021)”.

…and so much more!

SIGN UP / LOGINResponses