您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

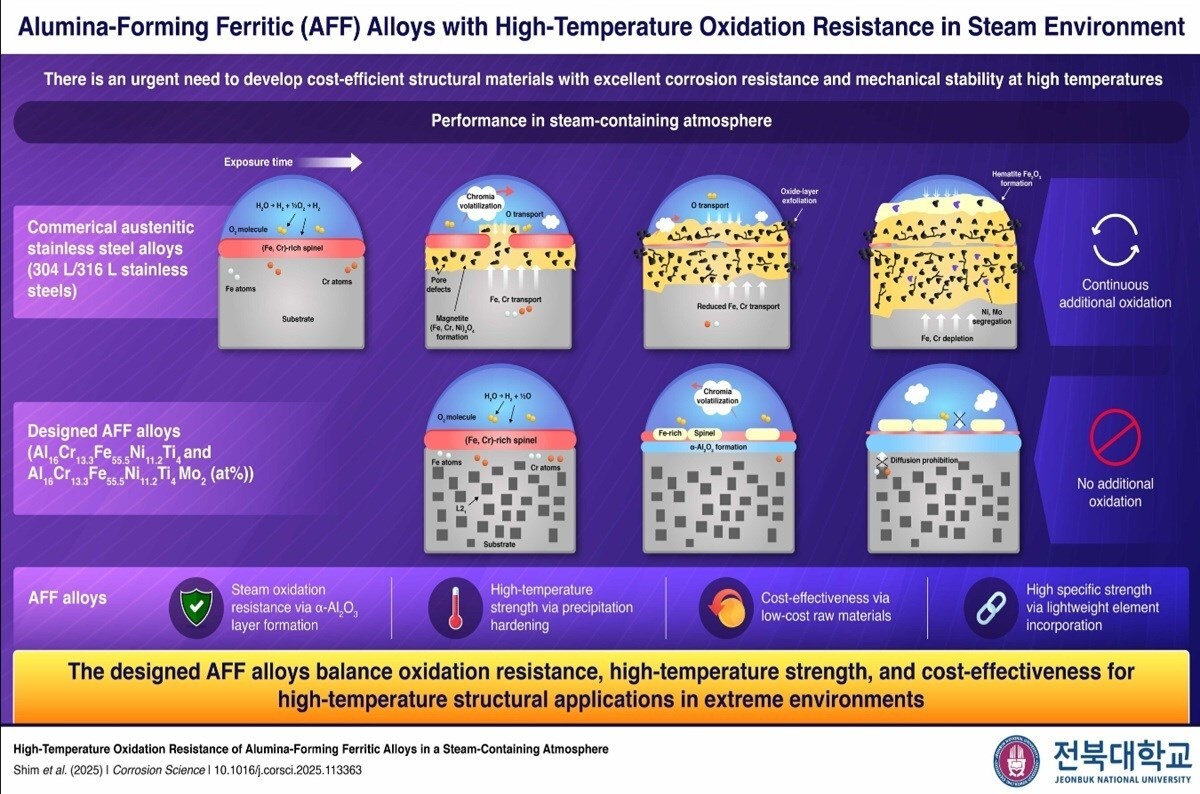

There is an increasing demand for novel materials with high-temperature oxidation resistance in harsh environments. Now, a joint research team from Jeonbuk National University and Korea Institute of Materials Science have demonstrated promising alumina-forming ferritic alloys that exhibit high-temperature oxidation resistance even under prolonged steam exposure. They achieve an outstanding balance between steam oxidation resistance, high-temperature strength, and cost- effectiveness, making them lucrative for high-temperature structural applications in extreme environments.

{alcircleadd}To know more about the global primary aluminium industry 2026 outlook, access the report “Global ALuminium Industry Outlook 2026”.

The emergence of carbon-neutral energy systems such as high-temperature electrolysis, solar thermal power plants, small modular reactors, and hydrogen- and ammonia-based processes has necessitated the development of novel structural materials that exhibit outstanding corrosion resistance and mechanical properties even at high temperatures and under harsh environments. Notably, traditional austenitic stainless steels (ASSs) fail in these conditions. Ni- and Fe-based heat-resistant alloys possess protective chromia (Cr2O3) and/or α-alumina (Al2O3) oxide scales; they also suffer from various limitations. Therefore, there is an urgent need to design cost-efficient self-protecting alloys with active α-Al2O3 scale formation capability and high-temperature phase stability.

Recently, in an innovative breakthrough, a team of researchers from the Republic of Korea, led by Associate Professor Jae-Gil Jung from the Division of Advanced Materials Engineering at Jeonbuk National University and Principal Researcher Ka Ram Lim from the Extreme Materials Research Institute at Korea Institute of Materials Science (KIMS), and including postdoctoral researchers Dr. Sang-Hwa Lee and Dr. Sang Hun Shim from each institute, developed alumina-forming ferritic (AFF) alloys using the concept of high-entropy alloys.

Read More: Europe imposes anti-dumping duties on imported fused alumina from China

"Our research presents a novel alloying strategy that simultaneously improves heat resistance and oxidation/corrosion resistance while maintaining economic feasibility. This dual improvement is important because it enables materials to stay stronger and more durable in extremely high-temperature environments," remarks Prof. Jung.

Now, the researchers have investigated the high-temperature steam oxidation behaviour of their earlier reported AFF alloy Al16Cr13.3Fe55.5Ni11.2Ti4 (at per cent) and its new variant containing an extra 2 at per cent Mo. Their present findings were made available online on October 12, 2025 and have been published in Volume 258 of the journal Corrosion Science on January 1, 2026.

"The body-centred cubic-based AFF alloys can accommodate much higher amounts of Al than face-centred cubic-based AFA alloys, making them more favourable for the formation of a uniform and dense protective scale," explains Dr Lim.

AFF alloys also demonstrate superior high-temperature specific yield strength comparable to that of Ni-based superalloys. Notably, Mo addition provides mechanical strengthening without compromising oxidation resistance.

These materials can operate under extreme conditions, with potential real-life applications including reusable space launch vehicles, advanced armour materials, molten salt reactors, thermal energy storage systems, high-temperature steam electrolysis, ammonia-cracking reactors, and lithium-ion battery recycling.

By focusing on low-cost alloy systems, which could accelerate their adoption in practical, large-scale applications in the coming 5- to 10-year period, these materials will make a real impact in everyday life.

Must read: Key industry individuals share their thoughts on the trending topics

Note: This article has been issued by PRNewswire and has been published by AL Circle with its original information without any modifications or edits to the core subject/data.

Responses