您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

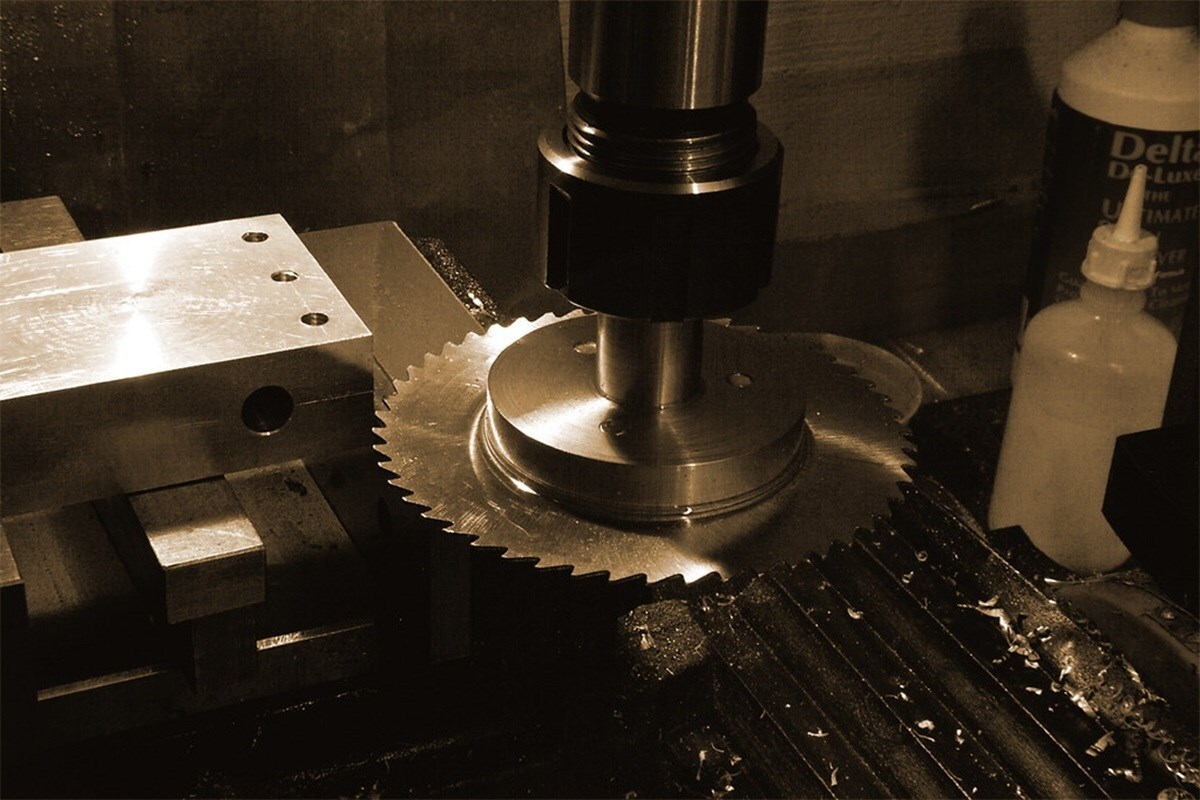

Walter has expanded its Tiger·tec Gold thread milling range with a new grade WSM37G, featuring PVD aluminium oxide coating. Rather than focusing on a single application, the new grade has been developed to operate across a wide spectrum of materials and machining conditions, delivering high temperature resistance and extended tool life, according to Walter.

{alcircleadd}To know more about the global primary aluminium industry 2026 outlook, pre-book the report "Global Aluminium Industry Outlook 2026” at a special price.

The product supports thread milling from a nominal diameter of 16 mm or UNC three-quarters and can be applied to steels, stainless steels, cast iron, non-ferrous materials, heat-resistant superalloys and hardened steels up to 55 HRC across ISO P, M, K, N, S and H materials groups.

WSM37G is a multi-layer coating system produced with physical vapour deposition. The aluminium oxide layer on it acts as a resistance to the elevated cutting temperatures, while a titanium aluminium nitride coating bonded to the carbide substrate enhances wear resistance. The coating stack is completed with a polished zirconium nitride top layer, finished in gold, which reduces friction at the cutting edge and allows wear to be identified more easily during use. A smooth rake face further supports stable cutting behaviour and controlled chip flow.

Also Read: VALCO’s smelter expansion plan to support 25,000 downstream jobs

The indexable inserts are produced with a positive base geometry and offer three cutting edges. Two insert variants are available. While the D67 geometry is specifically designed for generic use and prioritises long service life, the D61 version is unique in its built, by incorporating anti-vibration land which magnifies machining stability when used with long overhangs or under difficult cutting conditions.

Thread quality is supported through the use of chip breakers developed specifically for thread milling, along with defined corner radii designed to produce threads that meet a range of recognised standards.

Responses