您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

US-based semiconductor and electronic components manufacturer Vishay Intertechnology, Inc. (NYSE: VSH) has expanded its 193 PUR-SI series of miniature snap-in power aluminium electrolytic capacitors with voltage ratings of 550 V and 600 V. Produced under the Vishay BC components portfolio, the capacitors deliver up to 30 per cent higher ripple current than comparable devices in similar case sizes.

{alcircleadd}To know more about the global primary aluminium industry 2026 outlook, pre-book the report "Global Aluminium Industry Outlook 2026” at a special price.

In earlier series, designers would traditionally link three 400 V to 450 V capacitors in series and used voltage balancing resistors across each device. This method would add possible sites of failure and design complexity. So, in the new 193 PUR-SI series, with voltage ratings as high as 600 V, designers have removed the need for voltage balancing circuits, saving PCB space and reducing BOM costs. Longer capacitor lives and improved overall system reliability are other benefits of the higher voltage headroom.

Created for today’s high-power converters, the capacitors handle ripple currents up to 3.27 A and offer a useful life of 5,000 hours at +105 °C, translating to more than 25 years of operation in ambient temperatures up to +60 °C.

Read More: Export momentum sets stage for Bridgnorth Aluminium’s return to 24/7 operations

Capacitance values range from 47 µF to 820 µF, available in 25 compact case sizes from 22 mm × 25 mm to 35 mm × 60 mm. The devices feature a cylindrical aluminium case with a blue insulating sleeve, are RoHS compliant, and can be supplied with 3-pin keyed polarity snap-in terminals for improved PCB stability.

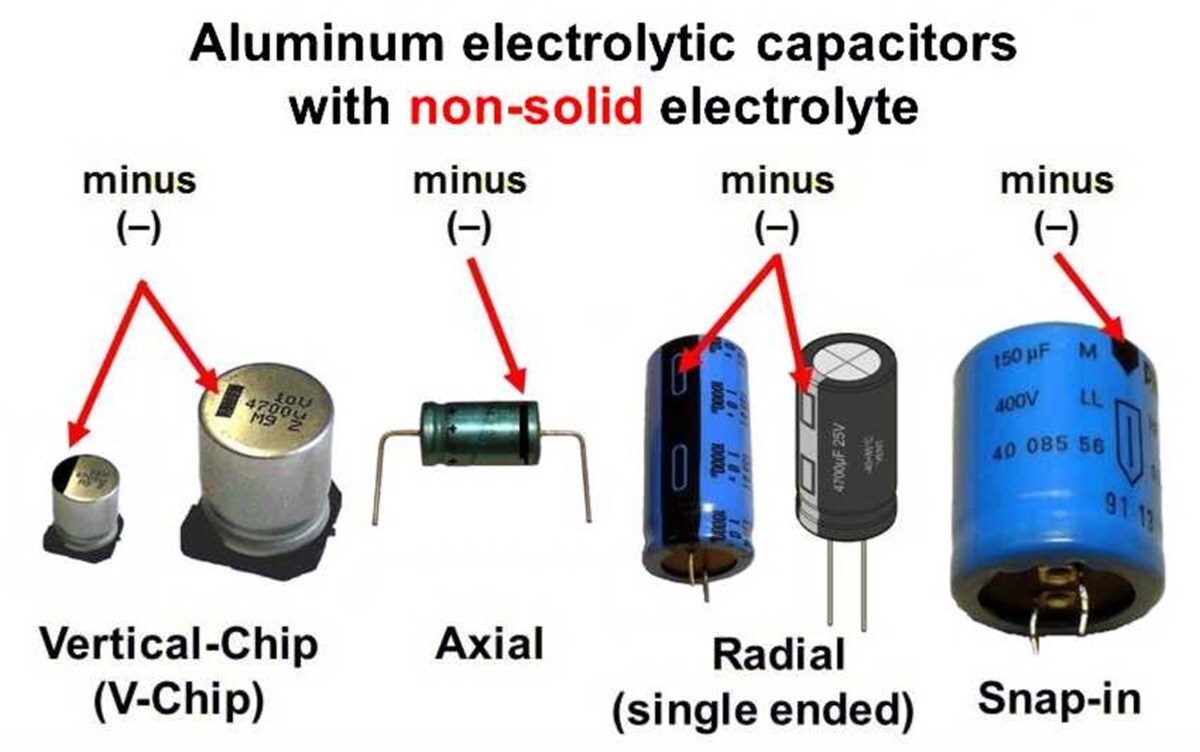

Designed as polarised aluminium electrolytic capacitors with a non-solid electrolyte, the 193 PUR-SI series supports demanding power applications requiring effective smoothing, buffering, and DC-link filtering. The devices are suitable for a wide range of systems, including EV and HEV powertrains, switch-mode power supplies, battery management systems, industrial motor drives, HVAC equipment, solar inverters, medical electronics, UPS installations, and welding systems. Rated voltage options range from 400 V to 450 V and from 500 V to 600 V. The series operates over a –40 °C to +105 °C temperature range and meets IEC 60384-4 / EN 130300 requirements.

The enlarged series is positioned as a workable alternative for next-generation high-voltage power designs, with production volumes now available with lead times of about 18 weeks and samples accessible in modest numbers from catalogue distributors.

Responses