In a significant turn of events, the relocation of a second consignment of aluminium dross from Win Process Company’s recycling facility in Rayong encountered a significant setback on May 19. The consignment, destined for an aluminium recycling facility in the Phanat Nikhom district of Chon Buri in Thailand, faced vehement opposition from local villagers, who refused to permit the unloading of the cargo.

This disruption follows a recent fire at the Rayong facility on April 22, which has heightened community concerns over environmental and health risks associated with aluminium dross. Aluminium dross is a by-product formed during the melting and processing of aluminium. When aluminium is in its molten state, it undergoes oxidation on the surface, resulting in the formation of a ‘skin-like’ layer known as dross. The fire incident has left the community wary of potential hazards, prompting the villagers in Phanat Nikhom to take a stand against the transfer.

The villagers' refusal underscores the escalating tension and mistrust between industrial operations and local communities, particularly regarding environmental safety and corporate responsibility. The protest compelled Win Process and the Industrial Works Department officials to halt the relocation of approximately 7,000 tonnes of aluminium dross to the Metalcom Company recycling plant in Chon Buri.

The initial shipment of 108 tonnes was successfully completed last May 18 without any issues.

Yesterday, Komen Phiewpoom, an official at the Industrial Works Department in Rayong, delivered a crucial update. The transportation of the material has been temporarily halted due to the high-stakes negotiations between Chon Buri’s governor and representatives of the protesting group.

The talks are scheduled to resume this afternoon, with participation from members of the House Land Affairs Committee and officials from the Industrial Works Departments in Chon Buri and Rayong.

Aluminium dross can serve as a filler in concrete, enhancing its flexural and compressive strength compared to pure cement. Additionally, it is used in steel plants as a desulphurising and deoxidising agent in refining furnaces.

Recycling aluminium dross offers several benefits, including reducing landfill waste and fluoride emissions, conserving natural resources, and the potential for multiple recycling cycles.

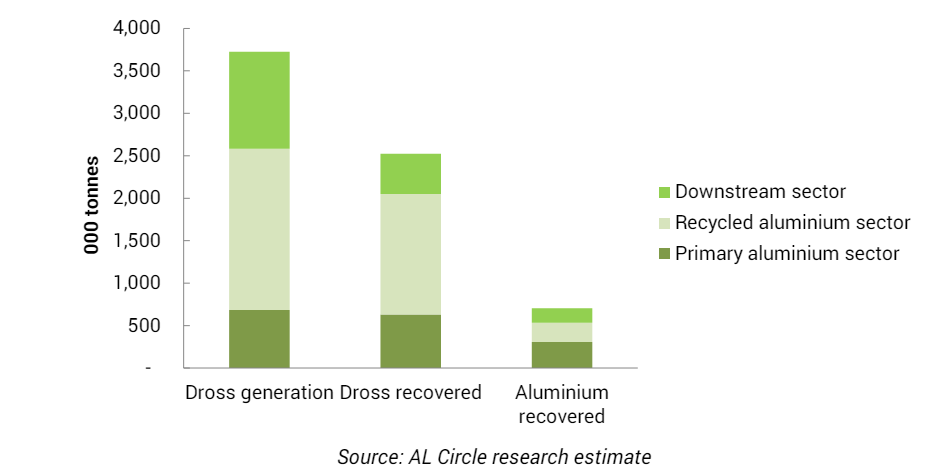

According to AL Circle’s industry-focused report, “Aluminium Dross Processing—A Global Review,” of the total 3.7 million tonnes of aluminium dross generated in 2022, an estimated 2.5 million tonnes was recovered and processed in various in-house facilities of aluminium producers as well as at third-party recycling facilities. Further processing of dross produced an estimated 705,000 tonnes of aluminium in 2022.

While there has been notable progress in dross recovery rates, particularly in developed nations with stricter environmental regulations, the aluminium industry recognises the need for further improvement. Any increase in dross recovery rates will significantly boost aluminium recovery.

Dross is typically mechanically removed by skimming from the melt surface before casting. The dross may be processed to recover some of the valuable metal but at a cost. Oxidation and dross formation thus represent a waste of expended energy, which in turn means an unnecessary cost.

Estimates of melt losses due to dross formation are in the order of up to 1% of total metal production. The quantity of dross produced varies and is influenced by factors such as furnace type, feedstock condition, and operational practices.

Responses