The Japanese multinational imaging and electronics company, Ricoh, adds the 6000 series aluminium alloy (AlSiMg) to its Binder Jetting (BJT) materials. The 6000 series is a kind of aluminium alloy frequently used in traditional production and brings excellent strength and corrosion-resistant qualities to various applications.

Ricoh stated that the 6000 series aluminium alloys are some of the hardest to sinter because they are more prone to oxidation and have a lower tolerance for impurities. The business introduced a 4000 series aluminium (AlSi) in 2020, which was made possible for Binder Jetting by using liquid-phase sintering technology. To create the 6000 series, Ricoh collaborated with the Bremen, Germany-based Fraunhofer Institute for Manufacturing Technologies and Advanced Materials IFAM and used the liquid-phase sintering technique once more.

The gases in the furnace are accurately controlled by Ricoh while sintering the 6000 series, and a highly degradable binder is used with a well-refined debinding procedure. Due to these technological advancements, it is now possible to create intricate 6000 series components using binder jetting.

"We believe that dialogue and co-creation with our customers are extremely important, as is technology development. We aim to accelerate collaboration with technical partners and customers by utilising this newly developed technology, through the activities at the Customer Experience Centre in Telford, the UK," said Takafumi Sasaki, Manager of the European AM department, Ricoh Futures BU, Ricoh Company.

Layer by layer, a binder droplet is selectively placed on a powder bed during the binder jetting process to create a green body. Following a debind and sinter procedure, the green component is densified to make the sintered part. Aluminium binder jetting has, however, run into difficulties since surface oxide prevents densification during the sintering process.

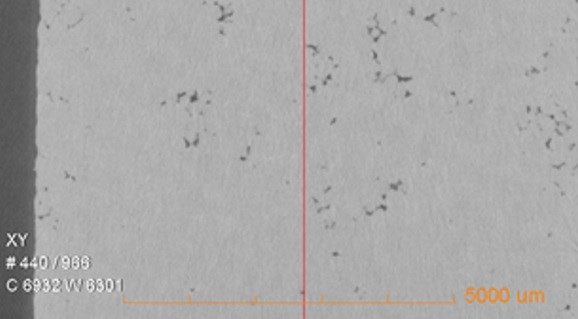

The relative density of the sintered 6000 series aluminium components created after Ricoh's 6000 series aluminium has been determined to be greater than 97 per cent. The sintered sample's X-ray computed tomography reveals no significant voids, either externally or inside.

According to Ricoh, qualities like tensile strength and thermal conductivity crucial for aluminium applications are comparable to those of traditional techniques. After T6, a typical thermal treatment for 6000 series aluminium, the tensile strength of the sample was reported to be about 250 MPa. Using the laser flash method, thermal conductivity was also tested and found to be 180 W/mK, the same as castings made of aluminium from the 6000 series.

Responses