2018 was a challenging year for the transport industry as the year saw a great deal of supply chain uncertainty due to tariffs on aluminium. The demand growth was led by the automotive sector. Automakers and the automotive suppliers expressed concern over higher prices of raw materials eating up on profits. On the positive side, 2018 saw numerous product launches, collaborations, development of new materials, growing interest in additive manufacturing and many more, which had driven the aluminium demand. Let’s look back at the top transport news from our end user vertical.

The U.S. Environmental Protection Agency (EPA) released its final determination finding current fuel economy and greenhouse gas emissions standards for light-duty vehicles model years 2022-2025 are not appropriate. They announced that they would ease emissions standards for cars and trucks and set up new standards.

{alcircleadd}

The Aluminum Association said “the U.S. aluminium industry supports nearly 713,000 jobs and $186 billion in direct and indirect economic output and we look forward to continuing working with the Administration and other stakeholders to ensure final emissions and fuel economy standards are premised on facts, data and on-the-road examples. Vehicles made lighter through greater aluminium use offer consumers better performance, affordable choices, higher fuel economy, lower emissions and improved safety”.

The 10 per cent tariffs that were imposed by U.S. President Trump’s administration on imports of aluminium and steel from July had caused the prices to rise in the end –user segment. US automakers buy much of their raw steel and aluminium domestically, but they import some of the auto components from other countries. Duties had created a great deal of supply chain uncertainty for automotive-sector companies.

China raised tariffs on vehicles imported from the United States to 40 per cent after the implantation of U.S. tariffs on imported steel and aluminium. Rising trade tensions with Washington affected the automobile industry in China. China’s import of cars from the United States saw 30 percent drop in volume in the first 10 months of 2018.

Automobiles

Constellium announced it supplied aluminium automotive body sheets for the new Audi A6. The company delivered Surfalex® with high surface quality and particular hemming and roping properties for the doors as well as for the trunk. It also supplied Securalex® P6, a high-tech crash absorption alloy, for the hood of the Audi A6.

Sohar Aluminium partnered with their latest downstream customer, Synergies Castings. Sohar Aluminium will supply more than 24,000 tonnes of aluminium per year which will be used to produce high-end aluminium alloy wheels for automobiles. The wheels will be supplied directly to automobile manufacturers around the world.

Fiat Chrysler Automobiles, lightweight OEM parts supplier Nemak and Tennessee's Oak Ridge National Laboratory had collaborated to develop a new aluminium alloy for use in turbocharged engines, which is expected to offer better fuel economy.

Germany's Trimet Aluminium completed the sale of its automobile parts unit to China's Bohai Automotive Systems. The transaction took place via a German subsidiary and Bohai Automotive now holds 75 per cent shares in TRIMET Automotive Holding GmbH.

The Egyptian Mint Authority announced it is working on a project to locally manufacture aluminium number plates for vehicles. About 600 kilograms of aluminium had already been manufactured and tested at European factories to guarantee high quality.

Morgan Motor Company confirmed to launch an all-new sports car in 2019.The new model, known internally as the ‘Wide Body’, is set to use an all-new bonded aluminium platform. The car’s chassis will reportedly be twice as stiff as the aluminium chassis used in the previous flagship Morgans.

China’s Qiantu Motors reportedly joined hands with California’s Mullen Technologies to begin building in the K50 sports car in the United States featuring aluminium frame and wheels.

The 2018 Lincoln Navigator and 2018 Ford Expedition won safety awards from the National Highway Traffic and Safety Administration. The body awarded the redesigned aluminium bodied Ford Expedition and the Lincoln Navigator perfect five-star overall crash ratings. Ford and Lincoln each said that the vehicles’ aluminium bodies had contributed significantly towards those perfect safety ratings.

Harley-Davidson announced its plans to shift its US manufacturing base to overseas in order to avoid burden of European Union tariffs. The European Union, in retaliation to U.S. tariffs on EU aluminium and steel exports, imposed tariffs on US products including bourbon, motorcycles and blue jean.

TRAINS

India's Raebareli MCF announced plans to manufacture its first aluminium shell coaches with speed range of 250 kmph. MCF is expected to manufacture aluminium coaches for Indian Railways. The coaches are likely to be featured with better corrosion resistance and to be rolled out in the early half of next fiscal year.

Alstom India is reportedly aiming to roll out trains made of aluminium, while at the same time, reading to double its metro coach building capacity at a plant in Sri City in Andhra Pradesh. Alain Spohr, Managing Director for India and South Asia, Alstom, said: "We will be doubling our capacity by setting up a new line that could manufacture 22 cars per month. We are also studying the feasibility for rolling out trains made of aluminium."

Midas Holdings Limited announced that CRRC Nanjing Puzhen Rail Transport Co., Ltd. secured three metro train car supply contracts worth RMB2.68 billion in China. Midas has a strategic 32.5% stake investment in CRRC Nanjing Puzhen Rail Transport Co., Ltd.

Odisha is keen to establish an integrated coach factory for aluminium-bodied train sets. Stating about this interest, Odisha Chief Minister Naveen Patnaik wrote a letter to Railways Minister Piyush Goyal.

Aircraft and Spacecraft

Dutch Kipp, engineering director for Landing Systems at UTC Aerospace Systems (UTAS) announced it is developing silver-based aluminium alloy for use in aircraft wheels for better strength and corrosion resistance. UTAS is pursuing a new silver-based aluminium alloy in collaboration with the OEM’s technical staff and its outside forging sources. The new alloy will offer 10% more “room-temperature” strength, 20% improved wheel strength at and after high-temperature exposure, and a 70% more damage tolerance and corrosion resistance.

Indian Space Research Organisation (ISRO) chairman K. Sivan called for a national effort to develop and produce advanced alloy materials to cater to the demands of future space programme. ISRO is now concentrating on aluminium and beryllium alloys which are suitable for making smaller structures. ISRO is focussing on domestically developed material in order to cut down on imports and lower the programme costs.

A consortium of four European organizations developed a method for producing self-reinforced fuselage panels by applying aluminium wire to said panels via additive manufacturing. Firms Stelia Aerospace and CT Ingénierie, and École Centrale de Nantes, all of France, and Constellium of the Netherlands developed the groundbreaking method under the auspices of their research and technology project DEFACTO (DEveloppement de la Fabrication Additive pour Composant Topologique).

Figeac Aero won its first contract from Boeing as a supplier of large structural aluminium parts for the 777X. It will supply the wing component measured 4 m (13 ft.) long, 1 m wide and 0.15 m thick.

Arconic signed a long-term multiyear contract with Boeing for the supply of aluminium sheet and plate for all models produced by Boeing Commercial Airplanes. It is the largest contract till date and captures growth in the build rate increased of the Boeing 737 program.

German-Russian joint venture “FITNIK” started operations in January 2018. Partners are the FIT Additive Manufacturing Group based in Lupburg (Germany), specialized in rapid prototyping and Additive Design and Manufacturing services, and NIK Ltd., based in Zhukovsky (Russian Federation), an engineering consulting firm active in the Russian and international aerospace market providing engineering and consulting. The cooperation combines two specialists united by one goal: To open up the Russian market for AM.

Lockheed Martin and Arconic announced a two-year Joint Development Agreement (JDA) for the development of customized lightweight material systems and advanced manufacturing processes, such as metal 3D printing, to advance current and next-generation aerospace and defense solutions—including new structures and systems not currently in existence.

Boeing warned about potential damage of the growing US-China trade row. Muilenburg was also of the view that tariffs on steel and aluminium could push up costs for aircraft manufacturers. Mr Muilenburg said that Boeing has not yet felt the impact of any tariffs on its business, but is concerned about the future effects brought about by retaliatory actions.

Marine Industry

The Trump administration’s 10 per cent tariff on aluminium imports is taking a toll on multiple American industries, including marine manufacturing. The implementation of these aluminium tariffs ... will drive up the costs of the aluminium used to manufacture more than 111,000 aluminium boats, such as pontoons and fishing boats, which make up 43 percent of new powerboat sales each year," Thom Dammrich, president of the National Marine Manufacturers Association, said.

The marine industry on both sides of the border in North America had warned that the U.S. tariffs on steel and aluminium and the metal trade war will take a mounting toll on its business.

According to the marine business owners, tariffs and counter tariffs are making the products expensive for them. Andy Blenkarn, owner of Desmasdon’s Boat Works in Ontario said the retaliatory tariffs of 10 per cent Canada imposed on U.S.-made boats had made the products expensive and the cost is also being passed on to consumers.

The National Marine Manufacturers Association (NMMA) urged the government to remove all duties on aluminium sheet in official comments and testimony, as the tariffs are causing harm to the industry.

The investigations and the resulting duties had caused higher production costs and material shortages on the marine and boating industry. Boat builders were seeing a 30 to 40 per cent price increase for aluminium sheet due to 10% tariffs on aluminium raw material, despite sourcing the material domestically.

Aluminium boats represent 44 percent of new U.S. boat sales each year and account for 3 billion dollars in retail sales.

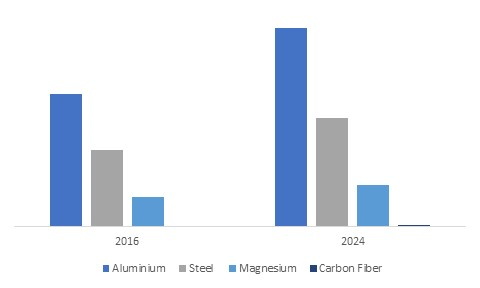

The escalating development in global automobile sector is poised to generate commendable growth avenues for automotive wheel market in the ensuing years. Automobile producers have been adopting new manufacturing techniques to comply with emission control regulatory norms. Researchers have also been implementing novel product designs and improvised concepts to increase the fuel efficiency of vehicles, which in turn, will boost automotive wheel industry size. As per the estimates, automotive wheel market was pegged at USD 80.8 billion in 2016 and is projected to exceed a valuation of USD 105 billion by 2024.

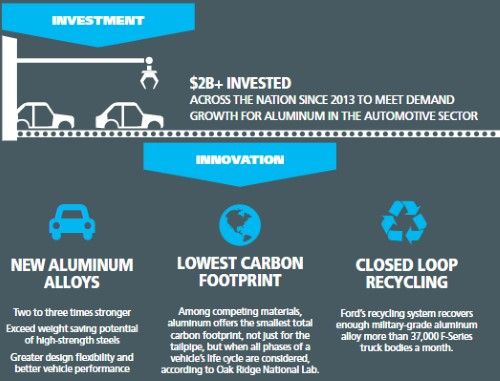

Major automotive manufacturers across North America and Europe are treading toward the production of lightweight vehicles, owing to the increasing concerns over environmental pollution. Aluminium is one of many materials that is used to construct these light weight vehicles, and has also been gaining immense popularity of late. As per estimates, aluminium-based automotive wheel market will surpass a revenue collection of USD 55 billion by 2024.

As per estimates, North America and Europe automotive wheel industry are projected to register a CAGR of 4.5% and 4% respectively over the coming seven years.

One of the major factors that have significantly influenced the regional trends is the implementation of strict regulatory norms to reduce carbon emissions by the government entities. Global Market Insights, Inc. projects the worldwide automotive wheel market to surpass a volume of 643 million units by 2024.

Responses