您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

Aditya Aluminium, part of Hindalco Industries Limited, has proudly launched Odisha’s very first 200 KLD Zero Liquid Discharge (ZLD) facility at its Sambalpur plant in Hirakud. This achievement marks a significant step forward in industrial water management, highlighting the company’s dedication to sustainable practices and innovative water conservation efforts.

Investment, technology & more

The company announced that its state-of-the-art facility, which represents an investment of around INR 20 crore (USD ), utilises cutting-edge Mechanical Vapour Recompression (MVR) technology to recycle and reuse industrial effluents right within the plant fully.

The recent developments reflect Odisha’s renewed focus on sustainable industrial growth. During its latest 140th meeting, the State Level Single Window Clearance Authority (SLSWCA), led by Chief Secretary Manoj Ahuja, gave the green light to 25 new industrial projects worth a whopping INR 4,739 crore (USD 540 million) across 13 vital sectors, such as steel, textiles, chemicals, tourism and renewable energy.

Also read: NTPC–Gujarat MoU signals stronger push toward India’s clean energy transition

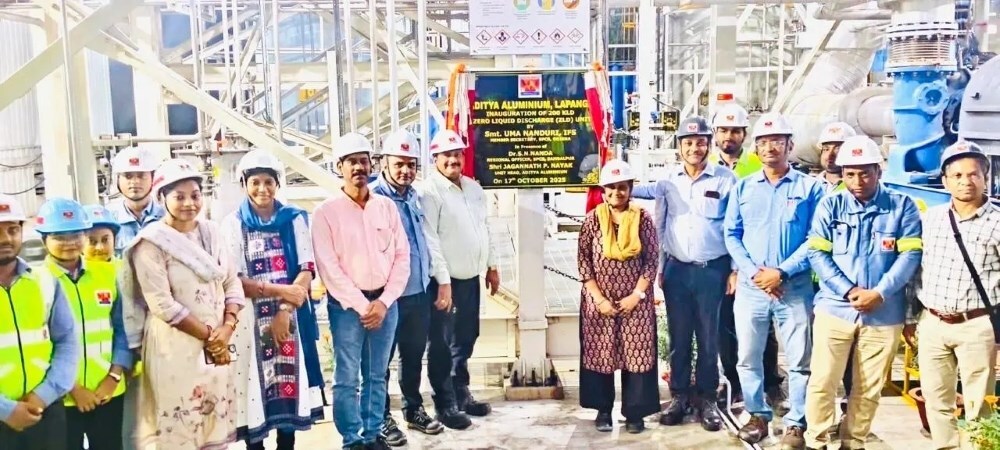

The plant had its official inauguration led by Uma Nanduri, who is the PCCF (KL) and also serves as the Member Secretary of the Odisha State Pollution Control Board (OSPCB).

All about the ZLD system

According to various reports, the newly launched Zero Liquid Discharge (ZLD) system works through an evaporation-condensation process that effectively recycles steam energy for treating wastewater. This innovative approach allows for the recovery of 90 to 95 per cent of clean water for reuse, eliminating any liquid waste discharge.

The system not only meets all ZLD standards but also significantly reduces the reliance on freshwater. In a recent statement, Aditya Aluminium emphasised that this project is in line with Hindalco’s larger goal of achieving water positivity across all its operations.

This groundbreaking initiative positions Aditya Aluminium as one of the first modular MVR-based ZLD systems in Odisha. It sets new standards for sustainable aluminium production and underscores Hindalco’s dedication to environmental responsibility and forward-thinking practices.

Read our latest e-Magazine on “Sustainability & Recycling: Aluminium's Dual Commitment”

Responses