HPQ Silicon Inc., a Quebec-based advanced materials engineering provider, has filed a provisional patent application for its latest innovative process developed by its France-based affiliate, Novacium SAS. The process is designed to transform black aluminium dross, a toxic by-product of aluminium recycling typically sent to landfills, into valuable resources.

The waste-to-energy process will use black aluminium dross as a feedstock to produce green hydrogen and transform the remaining material into waste neutralisation and valorisation of the solid by-products.

As rightly stated by Dr Oliver Moos, the Managing Director of Casthouse Engineering and Technology AG (CETAG) of Switzerland, this innovation has developed a promising approach to address critical materials like black aluminium dross, which has been a historic challenge for the aluminium industry worldwide.

The process is a result of a year-long PhD project initiated by Novacium with the Laboratory of Automation, Process and Pharmaceutical Engineering (LAGEPP) under the supervision of the University of Lyon 1, and the French National Center for Scientific Research (CNRS) to investigate the use of alternative additives to boost hydrogen yield from black aluminium dross recycling.

Dr Jed Kraiem, Chief Operating Officer of Novacium, updated: “The project has progressed rapidly, yielding highly encouraging results. These promising findings have captured the attention of several aluminium industry players, from recycler to equipment suppliers, as this waste presents a significant economic and environmental challenge for the aluminium industry.”

Dr Jed added, “The patent represents just the first step in establishing the value of this innovative process and demonstrating its transformative potential for the aluminium recycling industry. The immediate challenge is refining the process and proving its scalability. With the increasing pressure on aluminium recyclers worldwide to manage industrial waste responsibly, solutions like this—which deliver both significant economic benefits and a path toward a cleaner, greener future—are in high demand.”

Briefly about aluminium dross

There are two variants of dross – white dross and black dross. White dross is generated during primary aluminium smelting, and black dross is produced during recycling. Unlike white dross, black dross has lower aluminium content and is contaminated with salts, nitrides, carbides, magnesium and other compounds. In contrast, white dross contains 15 to 80 per cent aluminium.

At temperatures above the melting point of the salt flux mixture, the black dross consists of two immiscible liquid phases: aluminium metal and liquid salt-containing oxide particles and films.

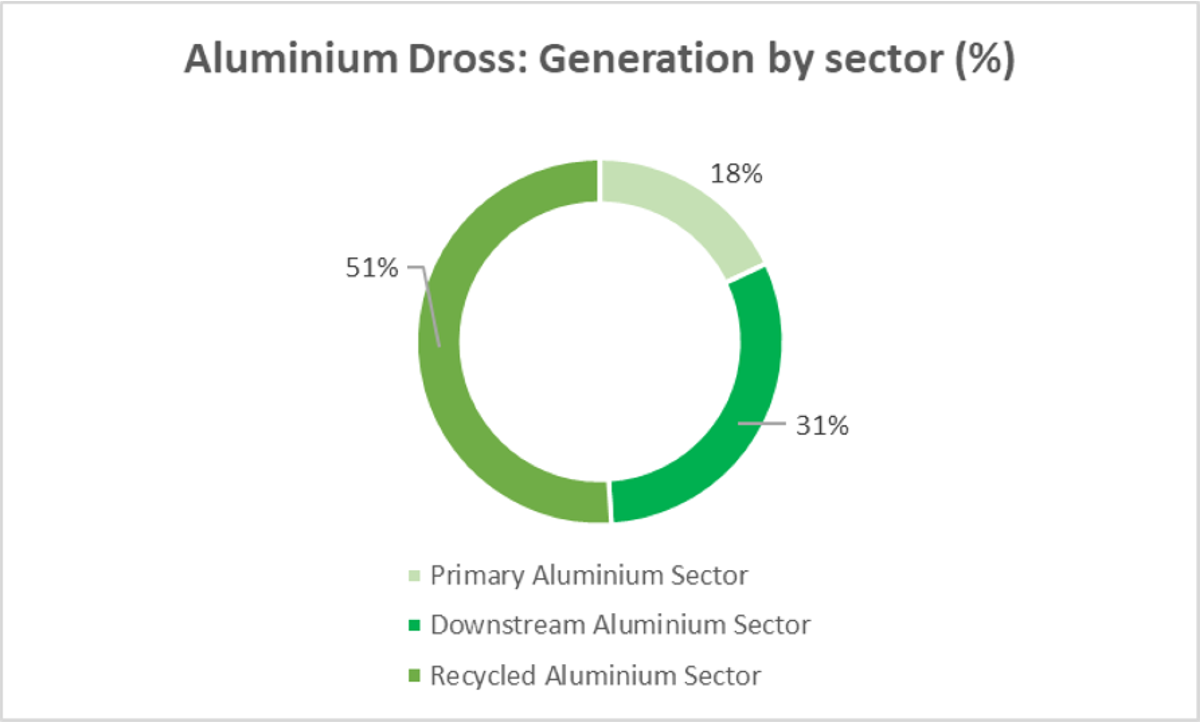

Globally, over 3 million tonnes of dross are produced annually, with 18% from primary aluminium smelting, 31% from downstream production, and 51% from recycling.

The three biggest disadvantages of black aluminium dross are

Responses