您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

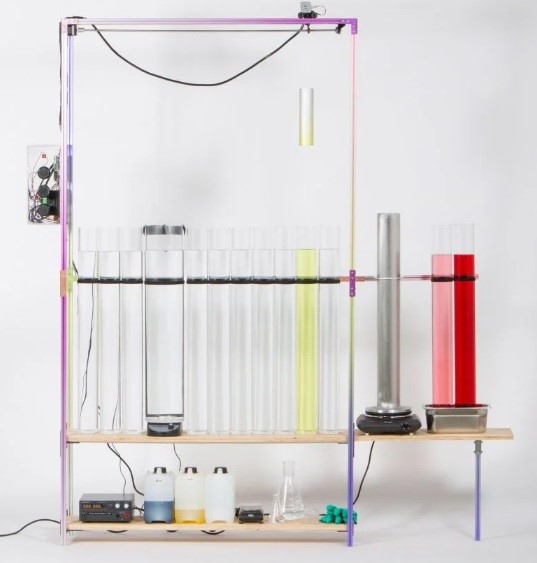

The Magic Colour Machine, designed by Loop Loop, a Dutch design studio, is fully automated aluminium-anodizing equipment that can be used to customise various aluminium components, was unveiled at the Alcova show during Milan Design Week. The machine can inexpensively and on small scale paint colours and gradients on aluminium as well as remove colours. As a result, components may be endlessly coloured with various finishes, perhaps increasing their lifespan.

Odin Visser and Charles Gateau, the founders of Loop Loop, who are located in Rotterdam, think the design can upend a sector heavily reliant on mass production. The two intend to launch a mass customization movement by adapting an industrial process into something that can be done on a smaller scale locally.

"We think we've found a sweet spot between customisability and affordability. With anodising, we can transform a relatively standard material into something unique and because we don't do it manually like craftsmen – it's an automated process – we can make it efficient and flexible,” said Odin Visser, one of the founders of Loop Loop.

A thin coating of aluminium oxide is applied to the metal's surface during the anodizing process. By putting the parts in an acid bath and passing electricity through them, this is accomplished. Gateau, a material science expert who also teaches at Design Academy Eindhoven, designed the Magic Colour Machine to control this procedure.

Anodization can be totally regulated at every level, thanks to the machine's programming by a tiny computer. This enables the creation of certain colours and finishes. Objects are merely transported through the liquid at a slowly escalating pace, opening up the potential of gradients.

"If you want a double gradient, we flip it around and do it again in another colour," added Visser.

Every object is given a special code that identifies its manufacturing process so that it may be easily duplicated or changed in the future. Supporting a circular economy is the goal.

"The main goal is to extend product life through its design and production, holistically looking at modularity, simplicity of build, reversibility, pieces of serial tracking, local and social production,” said Charles Gateau.

For the exhibition's eight days, five distinct colour schemes were applied to the Fade Pendant using the Magic Colour Machine. Based on the surroundings of the Alcova, the colours were chosen. Visser and Gateau also added their customised workstation with an aluminium frame to the area along with the machine.

This piece of furniture was entirely demountable and constructed using standard parts in keeping with their circular concept. The designers intend to investigate various applications for their micro-production line in the future, such as customising mass-produced scaffolding components.

Responses