您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

1. Introduction:

Industry 4.0 is a general concept of technological and organizational transformation of enterprises, which includes, among others digitization and automation of technological processes. One of the key branches for the development of the world economy is the production of aluminum, which consists of a number of stages, including heat treatment carried out with the use of industrial furnaces. SECO / WARWICK Company has developed modern tools dedicated for Vortex® furnace line, which fit into the Industry 4.0 concept and are aimed at increasing the efficiency and safety of production, as well as care for the quality of the processed product. In VORTEX® furnaces, intermediate or final heat treatment of load in the form of sheets or foil coils made of aluminum and its alloys is carried out, in particular, stress relief and recrystallization annealing. The aim of the article is to present selected solutions according to the Industry 4.0 concept, supporting the heat treatment of aluminum sheet coils carried out with the use of equipment belonging to the VORTEX® furnace line.

{alcircleadd}2. SeCoil®:

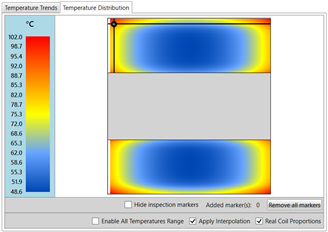

SeCoil® is a set of tools for designing, optimizing and controlling the process of heating aluminum coils in real time. The main element of the SeCoil® system is the mathematical model of load heating, which enables the determination of the temperature field in the cross-section of the coil at any time in the process without the need to use load thermocouples (Fig. 1).

Fig.1. The window of the SeCoil® simulator with the temperature field in the cross-section of a aluminum coil and the location of the so-called virtual control thermocouple

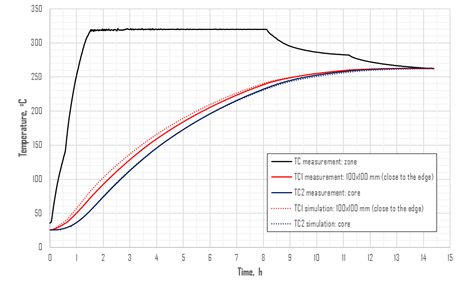

Mathematical model can be used both for process simulation and design (offline simulator), as well as real time process controller. Mathematical model as online controller, in cooperation with the supervisory system of the furnace, simulates the charge temperature field on a current basis using the information of the current conditions in the furnace heating chamber (temperature, outlet velocity of the heating medium) and the parameters of the heated load introduced into the control system (width, diameter, sheet thickness, type of alloy). SeCoil® allows you to choose the location of the so-called virtual control thermocouples, the indications of which can be used to control and regulate the process. Fig. 2 shows a comparison of indications of virtual thermocouples (SeCoil®) with indications of load thermocouples during the annealing process of an exemplary aluminum coil. The presented comparison shows very good consistence between simulation results and measurement results.

Fig.2. Comparison of indications of virtual thermocouples with indications of batch thermocouples

The following advantages of the SeCoil® system can be mentioned:

3. SECO/PREDICTIVE

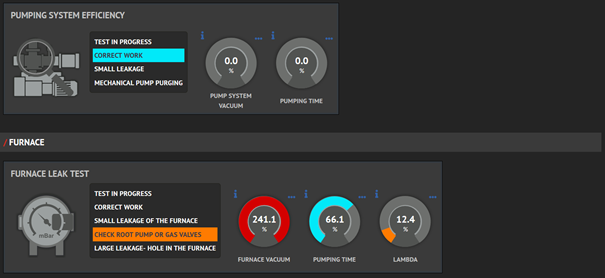

SECO / PREDICTIVE is an advanced device control system that enables detection of potential failures before their occurrence. This system is used to collect data from sensors and save them in the SECO / WARWICK cloud, and then to analyze the obtained information (Fig. 2). The solution is complemented by a remote access and notification system as well as a reporting and analysis function. Optionally, SECO / PREDICTIVE can cooperate with the SeCoil® system in order to analyze the charge heating curves for possible deviations from the norm.

Fig.2. SECO / PREDICTIVE software window with the analysis of the obtained information

SECO / PREDICTIVE can be used in VORTEX® furnaces, among the others, for:

In addition, the system provides the user with cyclical information about upcoming periodic inspections.

Responses