您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

Impact Minerals has unveiled the latest progress report of its transformative pre-feasibility study (PFS) for its Lake Hope High Purity Alumina (HPA) project in Western Australia, positioning itself as a potential global cost leader in the burgeoning battery and tech-grade alumina sector. Managing Director Dr Mike Jones detailed the findings and outlined a bold strategy for vertical integration, downstream processing, and by-product monetisation that could significantly amplify project economics through a recently released media release by the company.

Image for representational purposes only

Image for representational purposes only

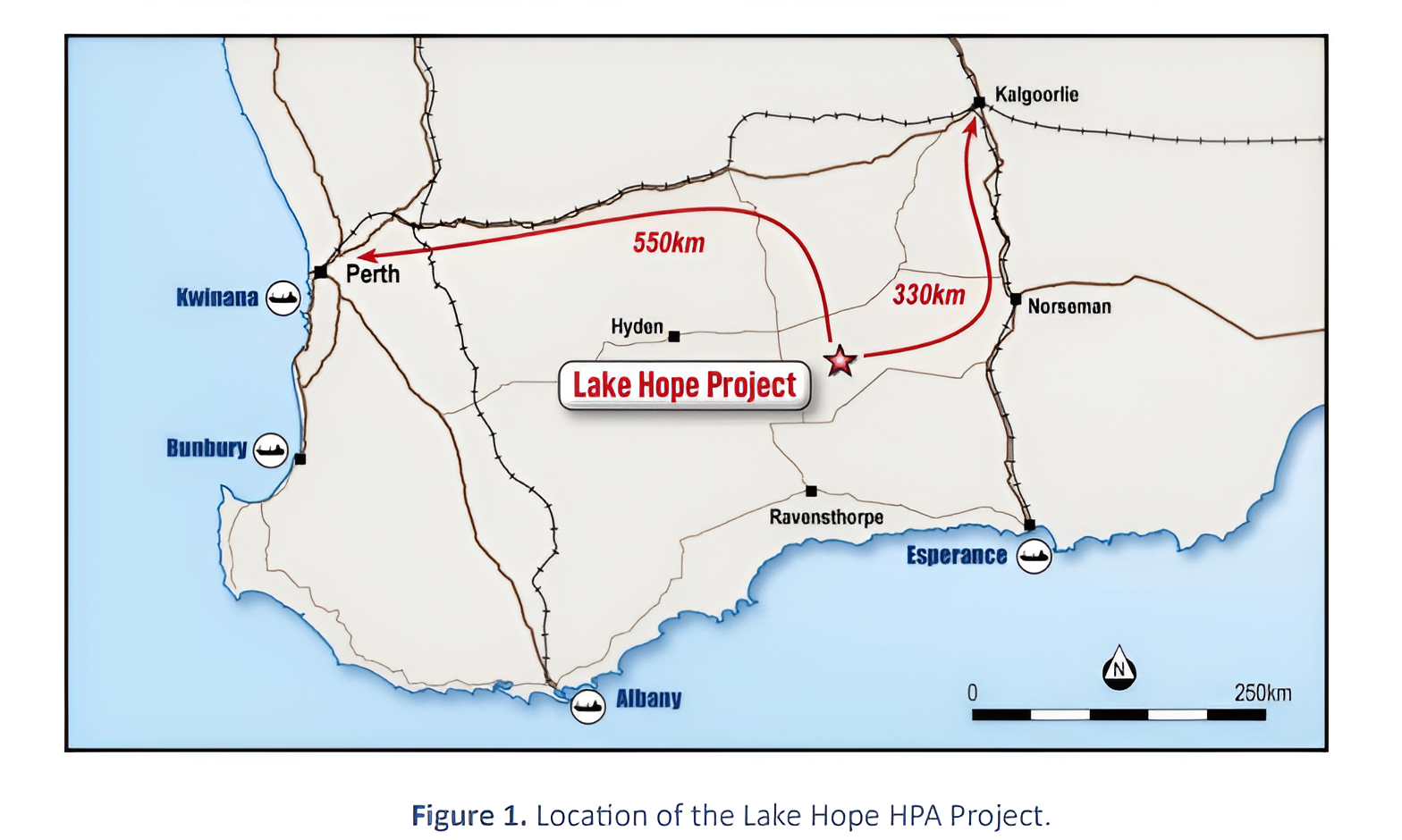

The PFS, conducted on the Lake Hope project located approximately 500 kilometres east of Perth, has revealed a compelling investment case. At the core of the results lies a net present value (NPV) of AUD 1.165 billion, notably excluding any contribution from by-products such as sulphate of potash (SOP), which the company sees as a valuable secondary revenue stream. According to Dr Jones, this valuation puts Lake Hope firmly on the map as a Tier-1 project.

Equally compelling is the project's capital profile. The estimated development capex stands at AUD 250-260 million, a relatively modest ask given the scale of returns. Dr Jones describes this as “a very achievable capital raise,” particularly when viewed against the backdrop of soaring global demand for HPA in lithium-ion batteries, LED lights, and semiconductor substrates.

Perhaps the most striking metric is Lake Hope’s anticipated operating cost: USD 4,500 per tonne of HPA, inclusive of the SOP by-product credit. The managing director claims that this figure would make Impact Minerals the lowest-cost HPA producer in the world.

An untapped bonus of by-products

The mineralisation at Lake Hope offers more than just alumina. The ore, when processed through Impact’s two-stage treatment method, yields a liquid by-product that crystallises into sulphate of potash, a high-value fertiliser, currently fetching over AUD 1,000 per tonne in the domestic market.

With Australia importing all its potash, Dr Jones notes that while SOP hasn’t been factored into the PFS modelling, a conservative valuation suggests it could add an additional AUD 140 million to the project’s NPV, potentially lifting it to over AUD 1.3 billion.

“This could be a significant second revenue stream for us,” he said. “It enhances our economics without any additional capital expenditure.”

HyPura — A strategic bolt-on for vertical integration

In a move designed to secure downstream flexibility and expand processing capabilities, Impact has acquired 50 per cent of the HyPura technology assets and IP previously owned by a competitor that entered administration. HyPura’s proprietary method for producing HPA dovetails naturally with the Lake Hope ore body. The technology has already shown compatibility in lab-scale testing, and the plan now is to validate those results through pilot-scale production over the next six months.

“The feedstock for the HyPura process contains the same elements and minerals we have at Lake Hope,” Dr Jones explained. “We’ve already trialled the backend of HyPura’s process with our ore, and it worked. If the integration is successful, we could drive costs even lower and secure a fully in-house, vertically integrated supply chain.”

Membrane technology, innovation at the process level

Another cornerstone of Impact’s future-facing strategy is the application of cutting-edge membrane technology through a Cooperative Research Centres Projects (CRC-P) grant, in partnership with Edith Cowan University. Borrowing from advancements in the water treatment industry, these membranes are now being adapted for use in mineral processing.

This technology could be applied at multiple points in the process flow sheet. First, it can improve the purity of SOP, enhancing its marketability. Second, it offers the possibility of reagent recovery, cutting chemical costs and improving environmental performance. Lastly, the membranes can be used to purify wastewater to near-potable levels, enabling safe discharge and minimising the project’s ecological footprint.

“This isn’t just about cost savings — it’s about pioneering a new standard in sustainable mineral processing,” said Dr Jones. “We’re leading the charge in integrating membrane tech into mining. It’s early-stage, but the potential over the next 12–24 months is enormous.”

With the PFS results now public, Impact’s immediate focus is on further testing of the HyPura process with Lake Hope material, commissioning the pilot plant, and advancing towards a Definitive Feasibility Study. Simultaneously, it will continue progressing the CRC-P membrane initiative and deepen its understanding of the SOP by-product’s economic potential.

Information credit: MiningNewsNet

Responses