您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

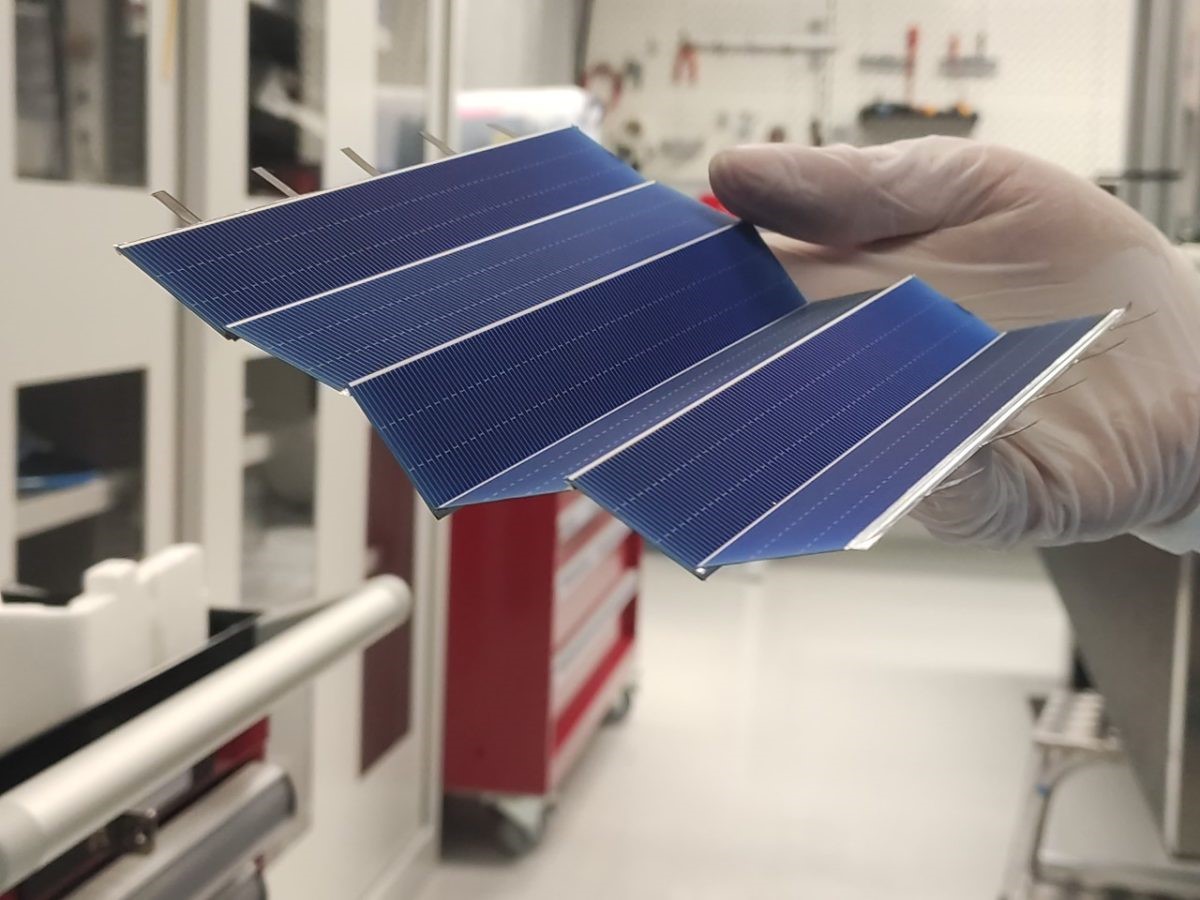

Researchers at Fraunhofer Institute for Solar Energy Systems ISE have evolved an innovative interconnection technology for shingled PV modules. The developed model removes the need for screen-printed busbars and also electrically conductive adhesives. Furthermore, it also enables solder-free aluminium interconnection which is highly cost-effective and an easy solution for the interconnection of separated cells in single solar modules.

According to Jan Nekarda, the Head of the Department of Production Technology at the Fraunhofer ISE, “We will show a mini-module made with our technology at our Fraunhofer ISE Booth at the upcoming Intersolar in Munich.”

Under the conventional process, electrically conductive adhesives (ECAs) are used for connecting the shingled solar cells. These ECAs are used for joining the real side busbar of one cell with the front side busbar of an adjacent cell. However, Jan Nekarda is still unclear how much cost-effective the proposed interconnection technology will be compared to the conventional ECA technology.

“Nevertheless we are confident, that a significant cost reduction will remain, due to the very high silver reduction of our technology,” added Nekarda. Furthermore, Fraunhofer Institute has joined hands with German PV production equipment provider Manz AG to build a machine. The machine will be built for industrial purposes through a project funded by the public.

Under the proposed model, the electrically conductive adhesives (ECAs) and screen printed busbars on both sides of the cells will be replaced by an aluminium foil which will be 8-μm-thick. The 8-μm-thick aluminium foil is known as FoilMet. The foil is connected with silicon nitride (SiNX) passivation using the laser metal bond process (LMB). According to the researchers, the LMB process is a non-passive method and is known to create a bond between the passivation of the cell and foil, without penetrating the passivation.

According to the scientist, “The silver (Ag) fingers and the aluminium (Al) fingers are microwelded to the foil using 300- to 700-μm-long line-shaped joints performed with a single 1-kW infrared continuous-wave laser leaving no necessity for busbar-like structures. The simplicity of FoilMet, which connects the fingers of adjacent cells without more intermediate layers than a single Al foil, is of great advantage compared to an ECA interconnection, with joints from the Al finger to the Ag busbar, to the ECA, to the Ag busbar, and the Ag finger, and therefore consisting of a multitude of layers.”

The German group of researchers compared the performance of their novel interconnection technology with that of the electrically conductive adhesives (ECAs). The comparison revealed that the unit fabricated using the foil achieved 21% efficiency and on the other hand, the one without the foil achieved 20.3%. Not only this, but the one without the foil also achieved 0.7% efficiency primarily due to the increased fill factor.

“Regardless of the cause leading to the disparity in the filling factor, in general, good interconnections using ECA can be achieved,” added the scientist.

The scientist further added, “FoilMet Interconnect, however, demonstrates the ability to reliably create interconnections with low series resistance and strings with high efficiencies.”

The German researchers also examined the foil’s performance at the YC200 ageing test. This was done to analyse the long-term stability of the aluminium interconnection. The analysis revealed that most of the shingle strings were able to withstand the pressure of encapsulation.

When enquired about the use of the new technology for a commercial production line, Jan Nekarda said that “unfortunately new processes are never ‘immediately’ applicable to commercial production and need some adaptations.”

He also added. “Compared to other innovations the necessary adaptations seem to be little. The metallisation layout has to be changed and the new machine for stringing has to be implemented in the production line. Since new materials are used extensive testing is needed, too.”

Responses