您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

Researchers at the University of Rochester have developed a technology that will enable aluminium to float on water by securing air bubbles inside.

{alcircleadd}The tubes themselves are quite slender, about one-fifth of an inch in diameter. However, when stacked together, they can be combined into larger assemblies. Such configurations could form the basis of floating platforms or devices designed to capture energy from the rhythmic motion of ocean waves.

For the global aluminium value-chain 2026 outlook, book our exclusive report “Global ALuminium Industry Outlook 2026"

Aluminium is one of the lightest structural metals, yet it is still about 2.7 times denser than water. If a solid piece is dropped into the ocean, it will sink immediately.

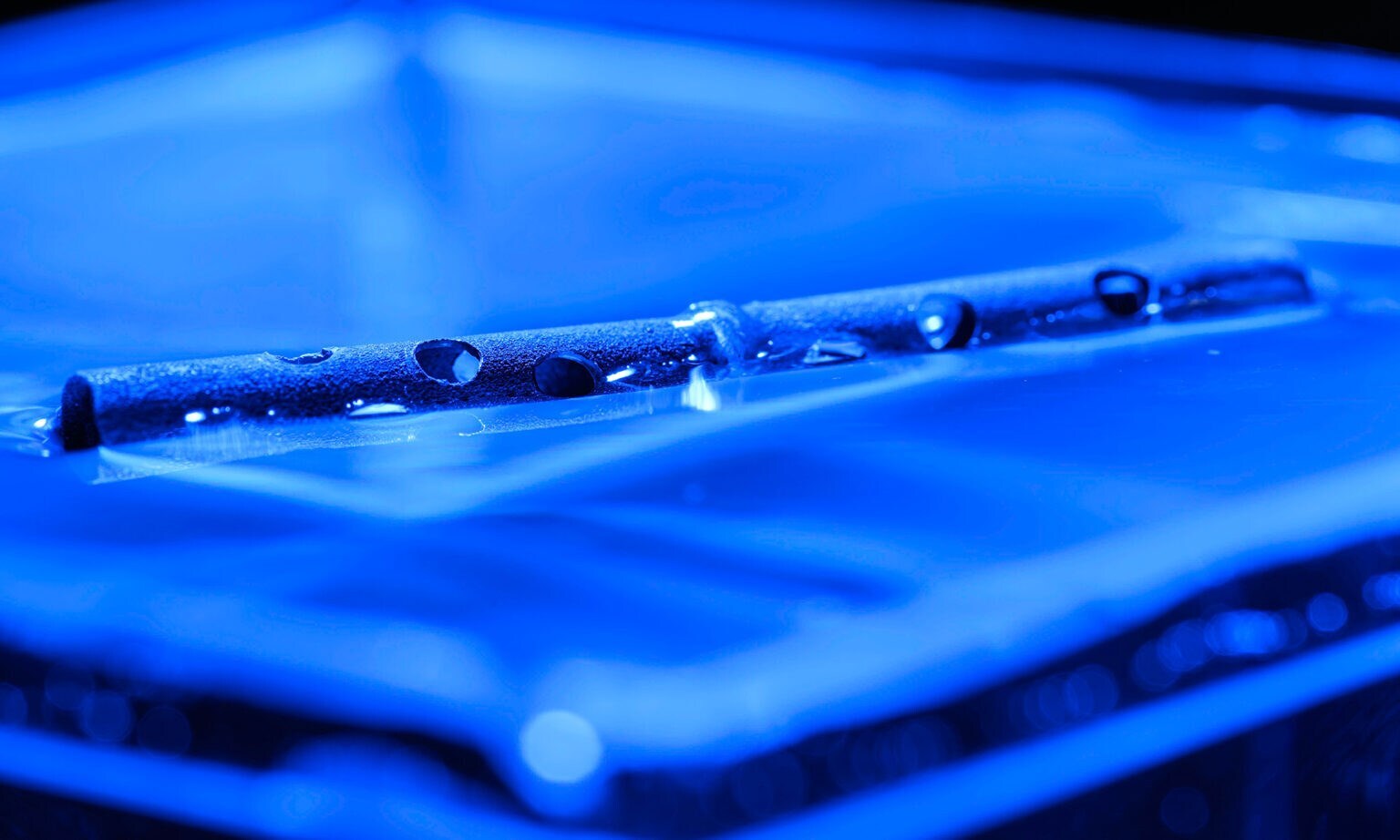

To create aluminium tubes that cannot sink, researchers at the University of Rochester chemically etched microscopic pits (small cavities formed by pitting corrosion) into the surfaces of the structures. These tiny textures make the surface highly water-repellent. Due to water’s surface tension, droplets cannot seep into the pits. Instead, they bead up and roll off almost immediately, leaving the surface dry.

The work was led by Dr Chunlei Guo, a professor of physics at the University of Rochester. He stated, “We have done quite extensive, really harsh environmental testing, and it will still stay floating.”

Also read: EEG collects 11,963 kg of aluminium cans, strengthening UAE climate action push

To test their durability, the researchers submerged the tubes under weights in both saltwater and water containing algae. Despite prolonged exposure, the tubes continued to repel water, preventing corrosion on the inside and stopping algae from growing there. Even when holes were drilled into the tubes, they retained their buoyancy and continued to float.

Don't miss out- Buyers are looking for your products on our B2B platform

Andreas Ostendorf, professor of applied laser technology at Ruhr-University Bochum in Germany, commented, “We are always looking for disruptive ideas…This can be a road map toward really penetrating this technology in many applications.”

This innovation significantly benefits ships, marine transport, and the broader aluminium industry. In shipbuilding, it could enhance safety by creating hull components (the main watertight body of a vessel) or flotation structures that remain buoyant even when damaged, reducing the risk of sinking.

*Image source: www.rochester.edu

Responses