您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

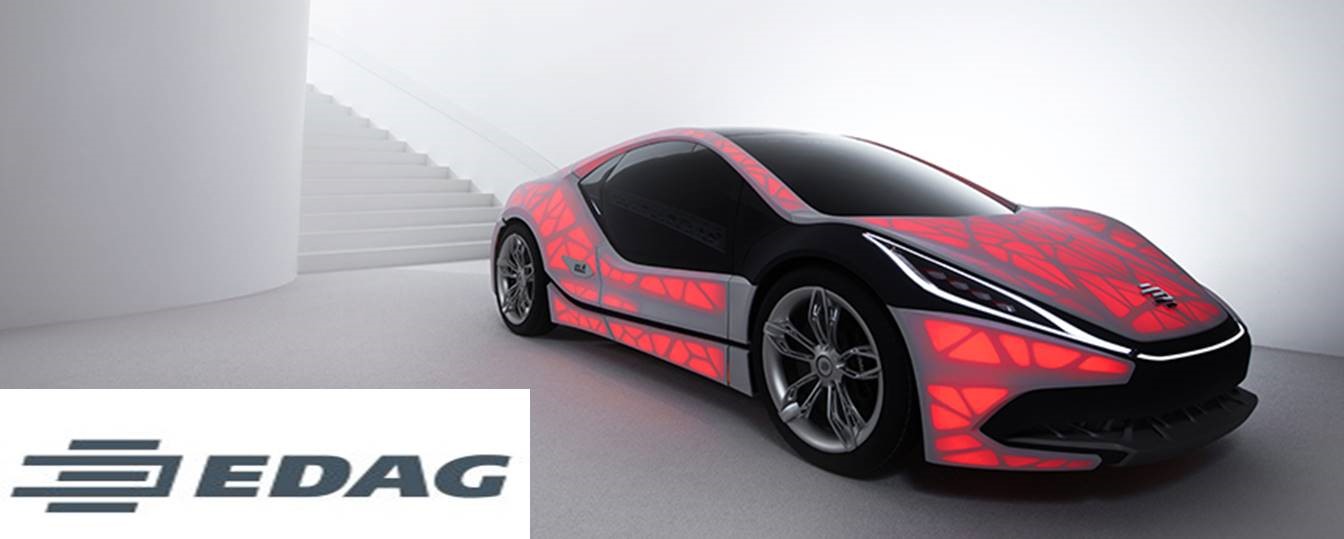

EDAG Group, the leading engineering technology service provider admits additive production has vast uncontested prospective for revolutionising the production of the future and at the same time achieving new dimensions for lightweight construction.

The aluminium alloys available presently do not yet fulfil the high demands required for them to be suitable for use in the automotive industry. The requirements include things like crash performance and their effectiveness in different situations.

As part of the BMBF-backed ‘CustoMat_3D’ research project, the EDAG Group, together with eight partners, has developed an aluminium alloy for use in the car, which can provide both higher strengths and higher elongations at the break, wherein the latter is very important, especially in the event of a crash.

In the last 3 years, EDAG Group says it has looked at the entire process chain from powder manufacture through simulation to component development.

The demonstration of performance was carried out by Mercedes-Benz and EDAG Engineering with the support of Altair Engineering. This integrated approach is intended to make additive production available to mass production processes. The recently discovered alloy can be used to establish car parts that are significantly reduced in weight.

EDAG Group says parts from different areas of the car were selected. It was possible to achieve an effective weight-saving both in the dynamic heavy load-bearing wheel carrier and a complex component with high rigidity requirements from the wheel box area. Some of the savings were over 30% of the expected potential.

The company says also, hybrid processes like laser deposition welding and bonding techniques were examined with the recently developed material.

EDAG Group says the newly developed alloy will be available officially in a few months under the brand name CustAlloy.

The project partners are already drawing a very positive conclusion. Due to the wide-ranging application as well as the corrosion-proofing already carried out, bonding technology and the many other requirements of the automotive industry, the alloy is destined for its first use in mass production.

EDAG was able to achieve all the project goals and the new alloy, its production process and the tested simulation methods have given experts effective tools to reduce car weight and the ability to use 3D print technology in mass production.

Responses