您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

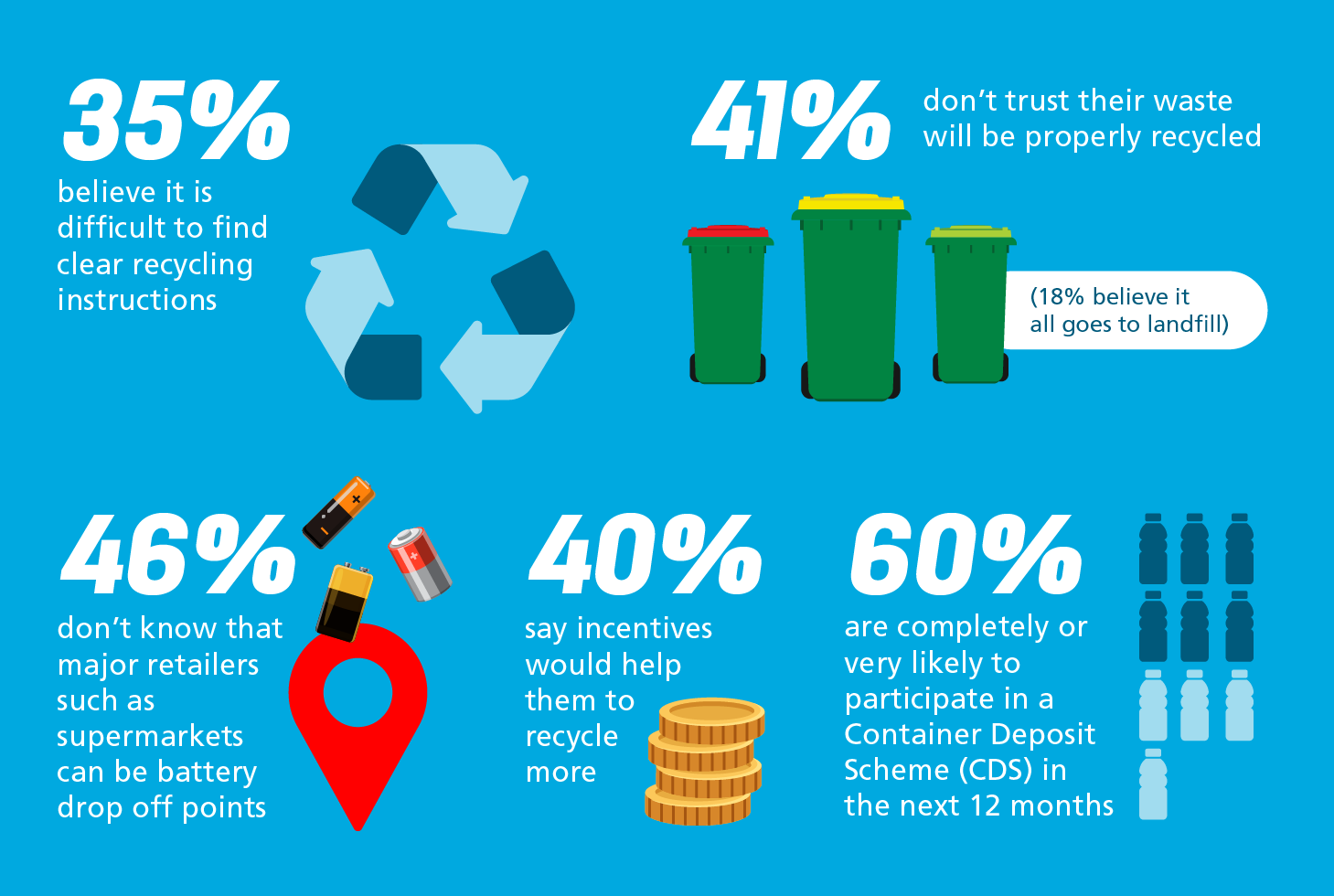

It is startling that Cleanaway's latest Recycling Behaviours Report for 2024 shows Australians need more confidence in recycling their waste.

The report indicates that two in five Australians harbour doubts about whether their waste is being recycled appropriately. Additionally, 18 per cent of respondents incorrectly believe that all waste ultimately ends up in landfills, casting a shadow over the perceived efficacy of recycling efforts.

As a proactive measure, Cleanaway's report aims to dispel these misconceptions. It provides a detailed overview of the recycling process at its facilities, showcasing how recyclable materials are transformed into new products. This reinforces the importance and effectiveness of recycling initiatives and serves as a valuable resource in addressing these misconceptions.

The recycling process begins when materials from the waste bin or recycling bin are collected and transported to Cleanaway’s Material Recovery Facilities (MRFs). At these facilities, items are sorted by material—aluminium, steel, paper, cardboard, plastic, and glass —using advanced machinery like optical scanners and conveyor belts and manual sorting by staff. Once sorted, the materials are sent to reliable onshore and offshore recyclers to be transformed into new products.

Aluminium and steel cans are common household recyclables, each undergoing a distinct recycling process. Industrial-scale magnets separate steel from other recyclables before it is melted down to remove coatings and formed into ingots, which are blocks of pure material. These ingots can then be used to manufacture new cans or parts for vehicles and aircraft. Similarly, aluminium is melted at high temperatures and repurposed into new products.

Cleanaway explains that paper is shredded and mixed with water to form pulp, which is then de-inked to remove any ink. The cleaned pulp is used to create new paper products like printing paper, toilet paper, and cardboard packaging.

Plastic materials are shredded into pellets and used to manufacture new plastic products. Nationwide Container Deposit Schemes support "bottle to bottle" recycling, where recycled bottle pellets are made into new bottles. Circular Plastics Australia (PET), a joint venture by Pact Group Holdings Ltd, Cleanaway, Asahi Beverages, and Coca-Cola Euro-Pacific Partners, exemplifies this initiative. These plastic pellets can also be turned into flakes to make items like polar fleece jackets and stationery.

At Cleanaway facilities, glass is sorted last on recycling conveyor belts due to its density and safety concerns. Once separated, bottles and jars are crushed and cleaned of labels, caps, and residual liquids. They are then either melted and reformed into new high-grade bottles or used in road construction as lower-grade material.

These examples demonstrate how closing the recycling loop supports a circular economy in Australia by reducing reliance on new virgin materials. In the 2023 financial year, Cleanaway reported recovering 431 kilotonnes (kt) of paper and 32 kt of steel and aluminium, highlighting the significant impact of effective recycling.

Cleanaway emphasises the importance of proper disposal and contamination prevention to improve recycling outcomes.

The fourth annual Recycling Behaviours Report, created with the Clean Energy Finance Corporation (CEFC), provides insights into Australians' recycling habits and aids Cleanaway's educational efforts.

Responses