您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

The clamour for using aluminium alloys in lightweight structures in environmentally friendly vehicles is seriously muted by weldability limitations of aluminium alloys. Welded aluminium alloy structures are weak, inconsistent and do not perform well in corrosive environments or when loaded cyclically in fatigue loading. Thick-thin structures with unfavourable thickness ratios are difficult to weld together. Robotic arc welds are notoriously inconsistent.

The aluminium industry needs to lead and facilitate large-scale and high-quality welding technology implementation. They should not depend on the welding houses to do this and not be oblivious to the shortcomings of the vehicle manufacturers’ aluminium welding technology capabilities.

{alcircleadd}Because of these issues, a number of opportunities are passing by the aluminium industry: lightweight automotive and other vehicular structures, stranded-wire aluminium cables for use as high-current carrying cables in Electric/Hybrid vehicles, and the same for use in their charging infrastructure, to name an important few. The aluminium industry’s lack of focus on weldability limitations is the culprit in all these cases.

This paper discusses reasons for the poor weldability of aluminium alloys and provides a cost-effective and easy-to-use solution that overcomes the issues and challenges for that poor weldability. Part of this has been published previously by the author in the Welding Journal.

CONVENTIONAL ALUMINUM WELDING: ISSUES & CHALLENGES

The difficulties in welding aluminium alloy structures stem from three main issues:

FOCUSED-MELT RESISTANCE WELDING (FMRWTM) - DESIGNED TO USE ALUMINUM RSW EQUIPMENT BUT WITHOUT CONVENTIONAL ISSUES AND CHALLENGES

Innovative Welding Solutions L.L.C. Detroit, Michigan has developed a unique and successful spot-welding process that mitigates a number of these problems. This revolutionary process, ‘Focused-melt Resistance Welding (FMRWTM)’ process was designed, developed and validated specifically to eliminate these traditional drawbacks of RSW of aluminium (Ref.1).

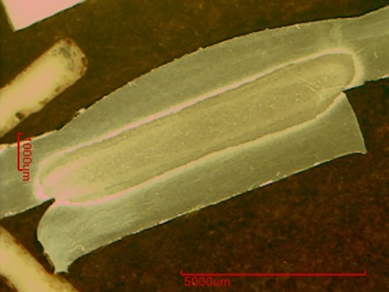

FMRWTM uses an aluminium alloy filler disc to focus the weld current at the weld interface. This causes the electrode-to-metal current densities to be an order of magnitude smaller than the actual weld current densities. With the electrode tips being water-cooled as in a typical resistance weld machine, this helps maintain electrode surfaces, while the outer surfaces of parts welded stay relatively cool. The selectable filler size also helps select the weld size. This means that nugget size is not limited by the sheet thickness. Tooling that enables quick follow-through and forging at the end of the welding process results in defect-free weld microstructures as shown below.

Unlike the typical RSW process, FMRWTM does not reduce thickness in the workpiece at the weld joint. This greatly increases the tensile strength of the welded joint.

Figure 1. A typical microstructure of an FMRWTM weld nugget in an aluminium alloy; the weld nugget is large in diameter with an aspect ratio of nearly 7:1 with the outer layers of the sheets welded remaining non-melted; the left side of the figure shows one of the mating sheets being torn in the peel test; the right side of the lower sheet is welded at its very edge with no adverse effects

COSMETIC WELDING BY AN INEXPENSIVE WELDING PROCESS

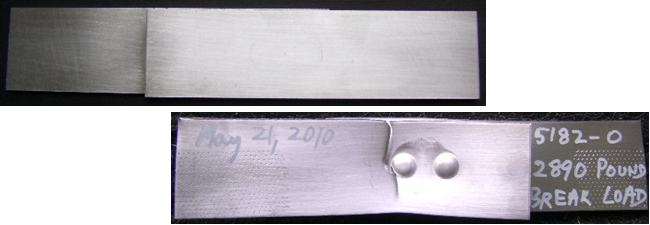

Resistance welding is also known to be the least expensive large-volume method of manufacturing metallic structures. The advantages of FMRWTM in enabling the use of this inexpensive manufacturing method in aluminium alloy structures are numerous. It ensures long electrode life and stable process quality using existing RSW equipment. The frequency of electrode dressing (once in 2000 to 3000 welds) is closer to that for steel spot welds. High-quality reliable welds can be produced with excellent cosmetic outer surfaces. Scope for non-destructive inspection is wide open due to the smooth outer-surfaces and a well-identifiable melted-and-solidified weld nugget. HAZ softening is limited to around 15% of original values to produce unprecedented weld strengths. These are often more than three times the minimum specified weld strengths per AWS D17.2. The weld size being selectable coupled with these hard HAZ regions lead to high load-bearing abilities and excellent fatigue life of the joint.

Figure 2. The cosmetic outer surface of a typical FMRWTM welded sheet; only slight colouration is visible at the weld nugget location; unprecedented high break load of nearly 12.85 kN for a 1.6 mm thick 5182-O sheet was obtained from this welded coupon when tensile-shear tested. This welded part contains two spot welds made with a centre-to-centre distance of nearly 15 mm

THICK-THIN ALUMINUM ALLOY COMBINATIONS ARE NOW READILY WELDABLE

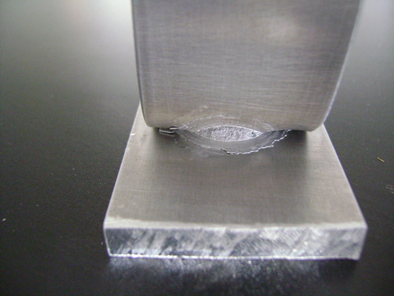

One major radical application of FMRWTM welding technology is unprecedented welding capabilities for thick-thin combinations of aluminium alloy sheets and plates. Thickness ratios of 1:10 were readily welded with no thinning of the thinner member being welded.

Figure 3. A 0.6 mm thick 6061-T6 sheet FMRWTM welded to a 5.0 mm thick 6061-T6 plate to yield a weld button size in excess of 10 mm diameter in a peel test. The tensile-shear strength of these welds is in the range 800 to 1000 pounds.

THICK FATIGUE-RESISTANT FMRWTM WELDS ENABLE MANUFACTURING LARGE STRUCTURES WITH REDUCED COSTS AND IMPROVED QUALITY

Thick aluminium plates can be successfully welded with considerably lower welding currents using the FMRWTM process. Because thick plates weld with excellent fatigue test results, they would be ideal for the railroad, flatbed truck and other heavy-duty applications requiring overall weight reduction. The use of these new Fatigue-Service-Capable spot welds enable light-weighting of large flatbed trailers and significantly reduce their manufacturing costs.

Figure 4. Peel tested FMRWTM spot weld of a 6.25 mm thick 6061-T6 plate to a 6.25 mm thick 5454-O plate. The process yielded a nearly 20 mm diameter weld nugget very close to the plate edges with excellent cosmetic outer surfaces. Weld shear-tensile strengths consistently exceeded 5000 Pound load

Figure 5. After a fatigue test specified by a flatbed manufacturer, the weld does not even appear to be tested except for the grip marks on the sheet surfaces.

NO MORE CLEANING REQUIRED PRIOR TO WELDING AN ALUMINUM ALLOY

The FMRWTM process helps eliminate the need for surface cleaning of the aluminium alloy components prior to welding, provided there is no heavy scale on the surface of parts welded. This process is not sensitive to other surface contaminants such as grease, ink, light oxides that form naturally and the moisture absorbed by such oxides and light dirt. Also, electrode tip dressing once in 250-300 welds is sufficient to result in reliable and stable weld quality.

WELDING OF ELECTRIC/HYBRID VEHICLE STRANDED ALUMINUM WIRE CABLES NOW ENABLED

The electric and hybrid vehicle industry is one of the fast-growing segments of the manufacturing industries in many parts of the world. Global vehicle volumes exceed 20 million/year and are growing rapidly. Each of these vehicles needs 6-7 cables that carry high currents of hundreds of amperes. Weldability issues with stranded aluminium wire cables have kept them from being employed in large volume in this industry segment. A major issue, though, is that the stranded-wire aluminium cables are not amenable to be welded to connectors through brazing (the soldering temperatures being too high) or laser welding (due to their high reflectivity). Successful FMRWTM welding of these cables in the author’ laboratory enables the use of aluminium stranded-wire cables welded to connectors in large-volume manufacture. These welded aluminium cables can help reduce both the costs (by more than 50%) and weights (also by more than 50%) of EV/Hybrid vehicle high-current cables and their charging infrastructure cables. This can represent a huge new opportunity for the aluminium manufacturing industry that is being missed presently due to weldability issues only.

Figure 11. Stranded wire aluminium cable FMRWTM welded to a brass connector through an interlayer material. The process can weld a 100 mm2 of an Aluminium cross-section in the cable readily

AEROSPACE ALUMINUM ALLOY GRADES ARE WELDED WITHOUT DEFECTS BY THIS PROCESS

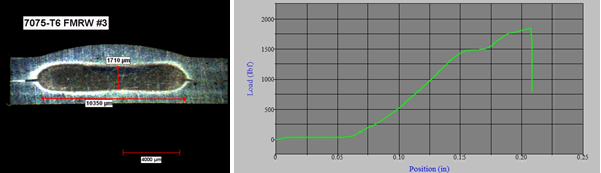

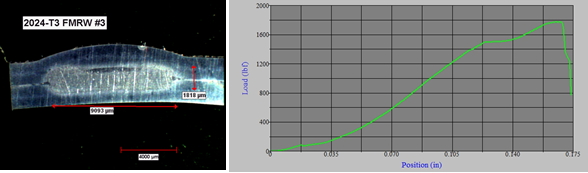

The use of low-melting range fillers of the 4000 and 6000 series makes aerospace alloy grades very weldable by the FMRWTM weld process. A macrograph, photos of peel tested welds, and results of shear-tensile tests on various aerospace alloys are shown in the figures below.

Figure 6. 10 mm diameter buttons from different alloys of thicknesses ranging from 1.6 to 2.5 mm FMRWTM welded in a single welder set-up using one set of weld parameters

Figure 7. The 7075-T6 FMRWTM weld shows good weld macrostructure in the weld nugget and much plastic deformation prior to failure in the tensile-shear test.

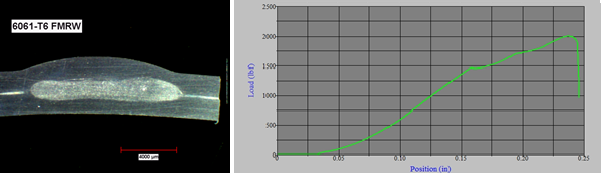

Figure 8. The 6061-T6 FMRWTM weld shows good weld macrostructure in the weld nugget and much plastic deformation prior to failure in the tensile-shear test.

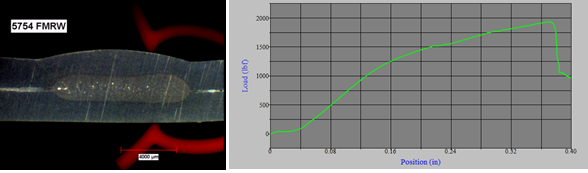

Figure 9. The 5754-T6 FMRWTM weld shows good weld macrostructure (but with some minor porosity) in the weld nugget and much plastic deformation prior to failure in the tensile-shear test.

Figure 10. The 5754-T6 FMRWTM weld shows good weld macrostructure (but with some minor porosity) in the weld nugget and much plastic deformation prior to failure in the tensile-shear test.

High strength steel welded to an aluminium alloy opens the door to new multi-material structures

IWSL is working currently with a large multi-national industrial house in the Detroit area to weld aluminium and high strength steel together in a metallurgically sound fashion using conventional large-volume welding methods. This will be the topic of a future paper by the author. Successful validation of this technology will help increase the use of aluminium alloys by facilitating the use of multi-material structures effectively welded together by presently used large-volume manufacturing methods. Such effective technology will help reduce the costs/weights of the vehicular structures.

THE ALUMINUM INDUSTRY SHOULD CAPITALIZE ON THE OPPORTUNITIES PRESENTED BY THE FRMWTM WELDING PROCESS

REFERENCES

Ananthanarayanan, V., “ Newer spot welding technology works well with aluminium”, Welding Journal, February 2017, pp 42-44.

Responses