您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

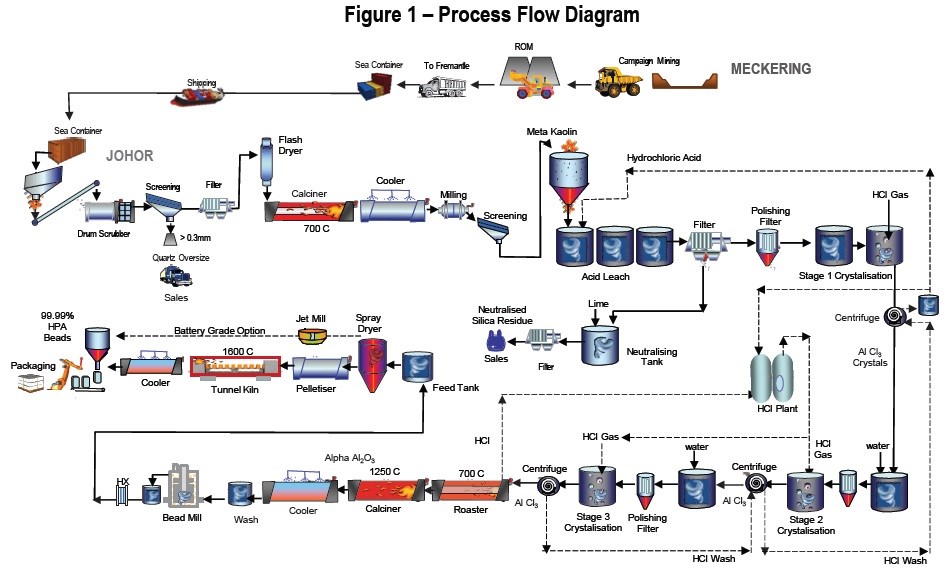

Altech Chemicals Limited has announced finalisation of the design for the capacity upgrade of its proposed high purity alumina (HPA) plant in Malaysia. The company had got the German engineering, procurement and construction (EPC) contractor SMS group GmbH (SMS) to do the project work for them. Altech has now completed optimisation of process flow sheet for the plant that will churn out 4,500 tonnes of HPA per annum from the current from 4,000 tpa, the company’s media release confirmed:

The majority of the changes compared to the previous flow sheet have impacted the HPA finishing section of the plant. This section now incorporates a flexible finished product line capable of producing HPA for both the synthetic sapphire industry (up to 4,500tpa of high density pellets) and HPA for the lithium-ion battery industry (up to 1,500tpa of powder at sub-micron particle size). Maximum plant output is designed at 4,500tpa HPA, with flexibility to balance the finished product mix.

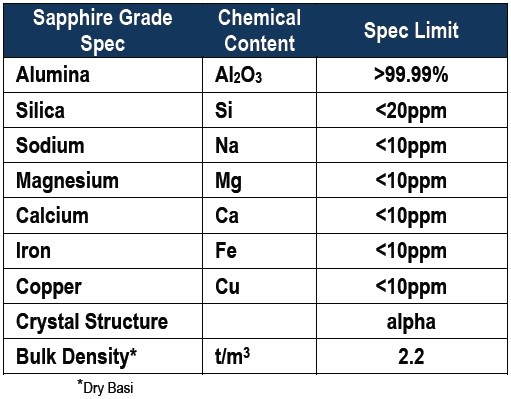

Altech's target customer base comprises two main industries: Sapphire for LEDs and Lithium-ion Battery. The Sapphire Grade HPA specifications are as follows:

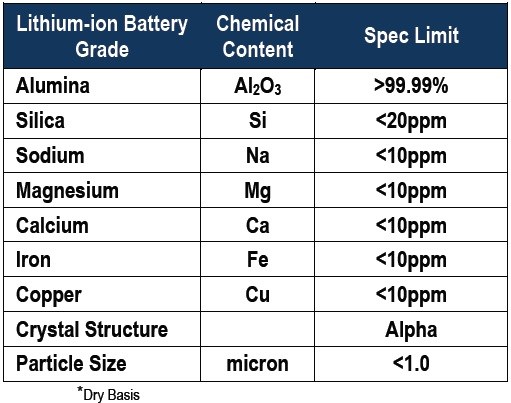

Altech's Lithium-ion Battery Grade HPA specifications are as follows:

Global HPA demand in 2016 stood at approximately 25,315 tonnes per annum. It is projected to grow at a compound annual growth rate (CAGR) of approximately 16.7%, with the HPA market size valued at about US$1 Billion in 2016, according to Persistence Market Research.

Responses