Alpha HPA has marked a landmark moment in the evolution of its Stage Two HPA (High Purity Alumina) First Project in Gladstone, awarding a flagship $20 million-plus concrete works contract to McCosker Contracting, one of the region's premier civil construction firms. This pivotal partnership places McCosker at the forefront of building the cutting-edge high-purity alumina facility, tapping into the company's deep local expertise and workforce.

More than just a contract, this deal exemplifies Alpha HPA's unwavering dedication to championing local industry and driving economic growth in Gladstone. With McCosker's trusted team delivering every major concrete element, the project is poised to unlock significant regional opportunities — a powerful boost for the community and a bold step forward for Australia's advanced manufacturing future.

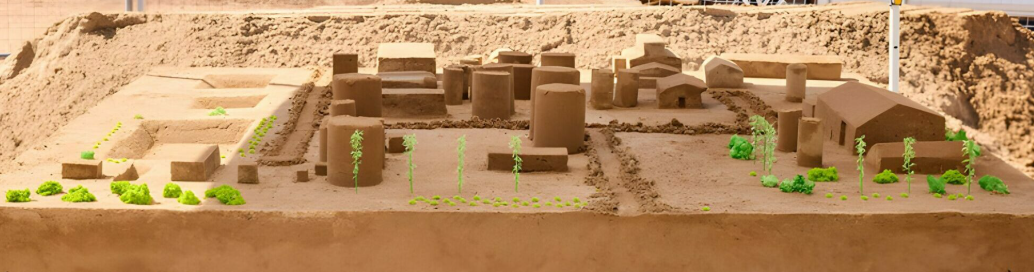

Set to redefine the global landscape for advanced materials, Alpha HPA's upcoming facility in Gladstone will claim the title of the world's largest single-site manufacturing plant for high-purity aluminium materials. Spanning 10 hectares of cutting-edge infrastructure, the facility will build upon the company's successful Stage One operation and proudly showcase a breakthrough innovation—Alpha HPA's fully Australian-owned and developed process IP.

At its core is a proprietary technology that transforms industrial feedstocks into ultra-high purity aluminium crucial for powering the technologies of tomorrow. It's not just a manufacturing milestone. It's a blueprint for a sustainable, tech-driven industry in Australia and beyond.

Stage 2 HPA project

The groundbreaking ceremony for the Stage 2 high-purity alumina (HPA) facility in Gladstone is expected to begin this June. Site establishment is scheduled for early June, with full-scale physical works to follow later in the month. The $550 million Stage 2 plant will mark the company's leap from pilot operations to full commercial scale, building on the success of its Stage 1 Precursor Production Facility (PPF), which has already demonstrated the capability to produce 500 kilograms of HPA per week at an impressive purity exceeding 99.995 per cent.

Once operational, the Stage 2 facility will be capable of producing over 10,000 tonnes of HPA equivalent annually, positioning it as the world's largest of its kind. It will harness Alpha HPA's proprietary technology to extract ultra-high purity aluminium materials from industrial feedstocks — a cleaner, more sustainable alternative to traditional methods.

Significant construction milestone

The contract signals a significant construction milestone as Alpha HPA accelerates development with the backing of a $400 million debt facility from the Australian Government and an additional $180 million in equity capital. With work now underway, the project promises to place Queensland at the forefront of advanced materials manufacturing while delivering substantial economic and employment opportunities to the region.

"Partnering with McCosker — a respected, long-standing family business embedded in the Gladstone community — ensures we are building this world-class facility with local strength and pride," said Alpha HPA Managing Director Rob Williamson in a statement on Monday.

Targeting booming sectors such as semiconductors, lithium-ion batteries, and LED lighting, the advanced materials produced at the facility are set to power key technologies of the future, all from the industrial heartland of Gladstone. The project is expected to support around 300 jobs during the construction phase, with approximately 120 permanent roles once operations begin, which will significantly boost the regional economy.

Federal backing has been instrumental in bringing the facility to life, with funding support drawn from several key sources, including the Northern Australia Infrastructure Facility (NAIF), Export Finance Australia (EFA), the $4 billion Critical Minerals Facility managed by EFA, and EFA's Commercial Account.

Also Read: Alcoa’s $1B tax win over Australia

Image Source: Alpha HPA

Responses