Achenbach Buschhütten, the specialist and world market leader for aluminium foil rolling mills and foil slitting machines, is pleased about a significant order from South Korea to deliver machines and equipment for a new battery foil production in the USA.

Achenbach's long-standing customer Lotte Aluminium, a manufacturer of aluminium foil for various applications, has agreed to set up a joint venture with Lotte Chemical to build a production facility for battery cathode foil. The two companies are subsidiaries of the Lotte Group, one of South Korea's largest conglomerates with over 90 business units and more than 80,000 employees.

The new battery foil plant, which will have an annual production capacity of 36,000 tonnes of foil and be able to equip about 4,000,000 electric cars and create 122 new jobs, is to be built in Elizabethtown, Kentucky. The American state is a leader in the fast-growing electric vehicle market and has established itself as a location for electric mobility through significant investments over the past two years. The Lotte Group expects the demand for batteries in the United States to experience tremendous growth due to the increasing demand for environmentally friendly electric vehicles. Thus, the demand for cathode foils will also increase by an average of 32% annually until 2030.

Achenbach, which has been active in the field of battery technology for several years, has become a specialist in rolling and processing sophisticated foil. Numerous customers, primarily from South Korea and China, have already been equipped with highly specialized machines and systems in the past. "We are pleased that we can now supply our pioneering technology to the USA after many years of deindustrialization. There will also be more production facilities for battery foils and cell production in Europe, which will hopefully soon be able to reduce the dependence on long supply chains. What is needed for this can only be done by us in Buschhütten!” says Achenbach President & CEO André E. Barten.

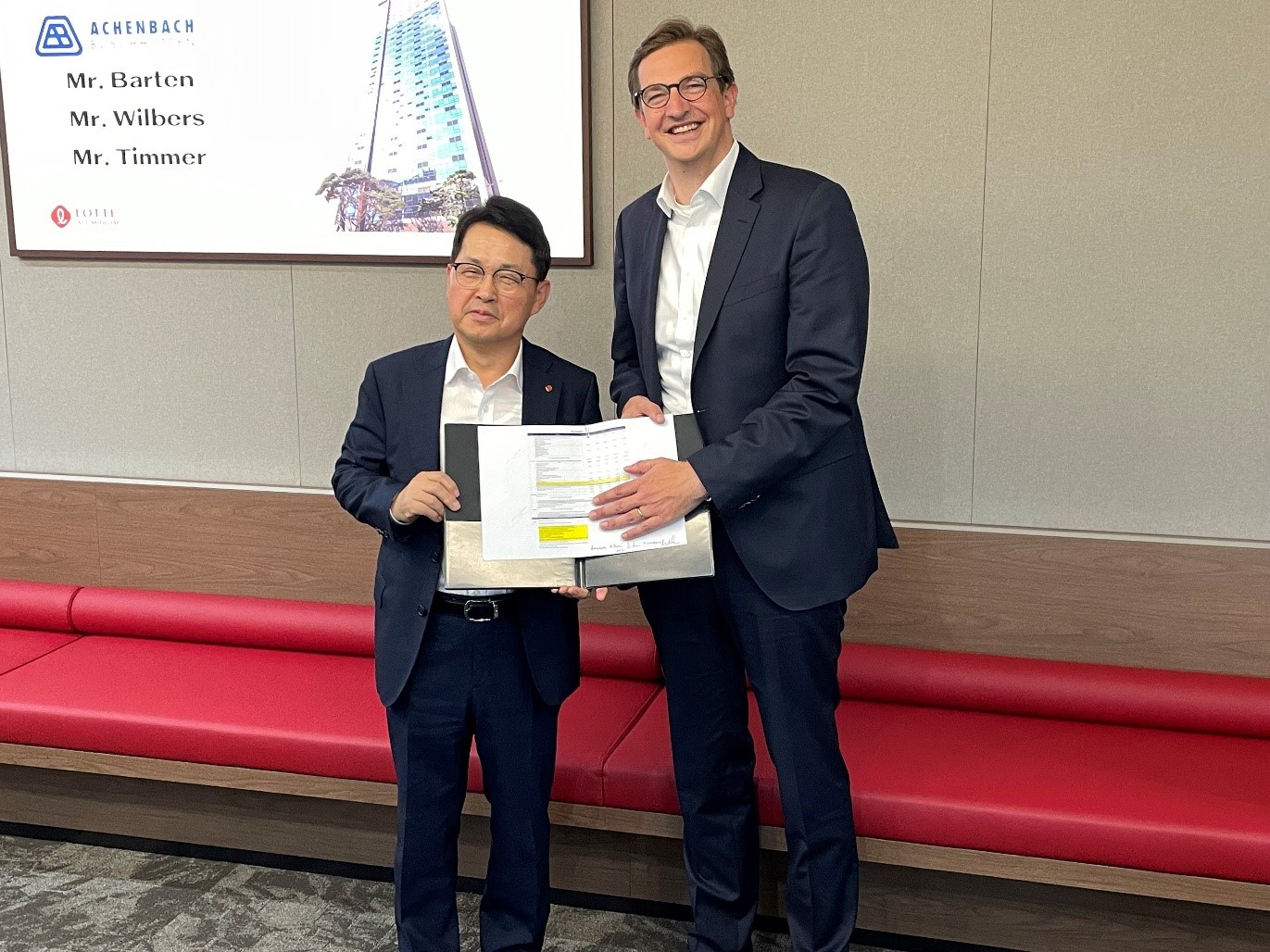

The fact that Lotte Aluminium decided in favour of Achenbach for this major investment is not only due to the expertise of the local machine and plant manufacturer in this field but also to the trusting business relationship between the two companies. Three decades ago, Achenbach delivered the first rolling mill for Lotte and only last year completed the installation of Europe's largest battery foil production in Hungary for the Korean producer. "Due to the successful cooperation, the project teams of both companies are closely connected, know and support each other. We have already mastered the mammoth task of ramping up such a large high-tech plant together once - the project in the USA is now another significant milestone, explains Thomas Timmer, Director of Global Sales at Achenbach and mainly responsible for the new order.

The new order is not only groundbreaking in terms of technology but also terms of sustainability. With its new mission statement GREEN.LEAN.DIGITAL, Achenbach is not only committed to paying attention to sustainability in its own production and everyday work.

"Ultimately, it is our products with which we have the greatest positive impact on the environment in the long term," emphasizes André E. Barten. "Our machines are characterized by innovative technology components and a high degree of automation, which have the lowest energy consumption and extremely low emission values through special exhaust air purification systems."

Production is expected to start in the US in 2025, with further expansion stages not ruled out. All machines and systems for this major project will be designed, manufactured and pre-assembled mainly at Achenbach - a clear commitment to the technology location Buschhütten.

Responses