您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

The expansion of renewable energies requires sustainable solutions in order to keep the industry's ecological footprint as small as possible. Whether for new installations or repowering – it is not only the technology that needs to be optimised for maximum energy yield; the material solutions used must also withstand a holistic life cycle assessment. This is where the aluminium recycler Speira and the construction specialist Bayards advocate light metal as a more environmentally friendly alternative for the construction of the nacelles of modern wind turbines.

Compared to conventional materials such as glass fibre-reinforced plastic (GRP) or steel, aluminium scores with clear advantages for the environment and efficiency.

"We see aluminium as a key material for the sustainable further development of the wind power industry. Its recyclability and technical properties make it an ideal solution for minimising the ecological footprint of modern onshore and offshore wind turbines," explains Reinhard Pritzlaff, Technical Advisor at Speira.

Sustainability through recycling

While GRP is based on petrochemical raw materials and is difficult or almost impossible to recycle, aluminium sets standards in terms of sustainability: 100 per cent of the material can be reused after each life cycle without any loss of quality, and recycling then only requires five per cent of the energy of the original primary production – an advantage that significantly reduces CO₂ emissions and makes aluminium a so-called permanent metal. This is why aluminium components retain their high economic value even at the end of their life cycle.

"With aluminium, we create almost closed material circularity that improves the environmental balance of wind turbines. This is not only good for nature – the energy-saving recycling also makes economic sense," Pritzlaff continues.

Lightweight, strong, corrosion-resistant, very good thermal conductivity

Aluminium also offers advantages over steel: Not only does it have a significantly lower weight, which makes it easier to transport and install the nacelles, but it is also highly resistant to corrosion. Nacelle cladding made of aluminium is maintenance-free and can be integrated into the nacelle's waste heat management system thanks to aluminium's superior thermal conductivity. This means, for example, that the necessary heat exchangers can be smaller. Despite its lower weight, aluminium meets all the strength and durability requirements that are crucial for modern wind turbines.

Collaboration with Bayards

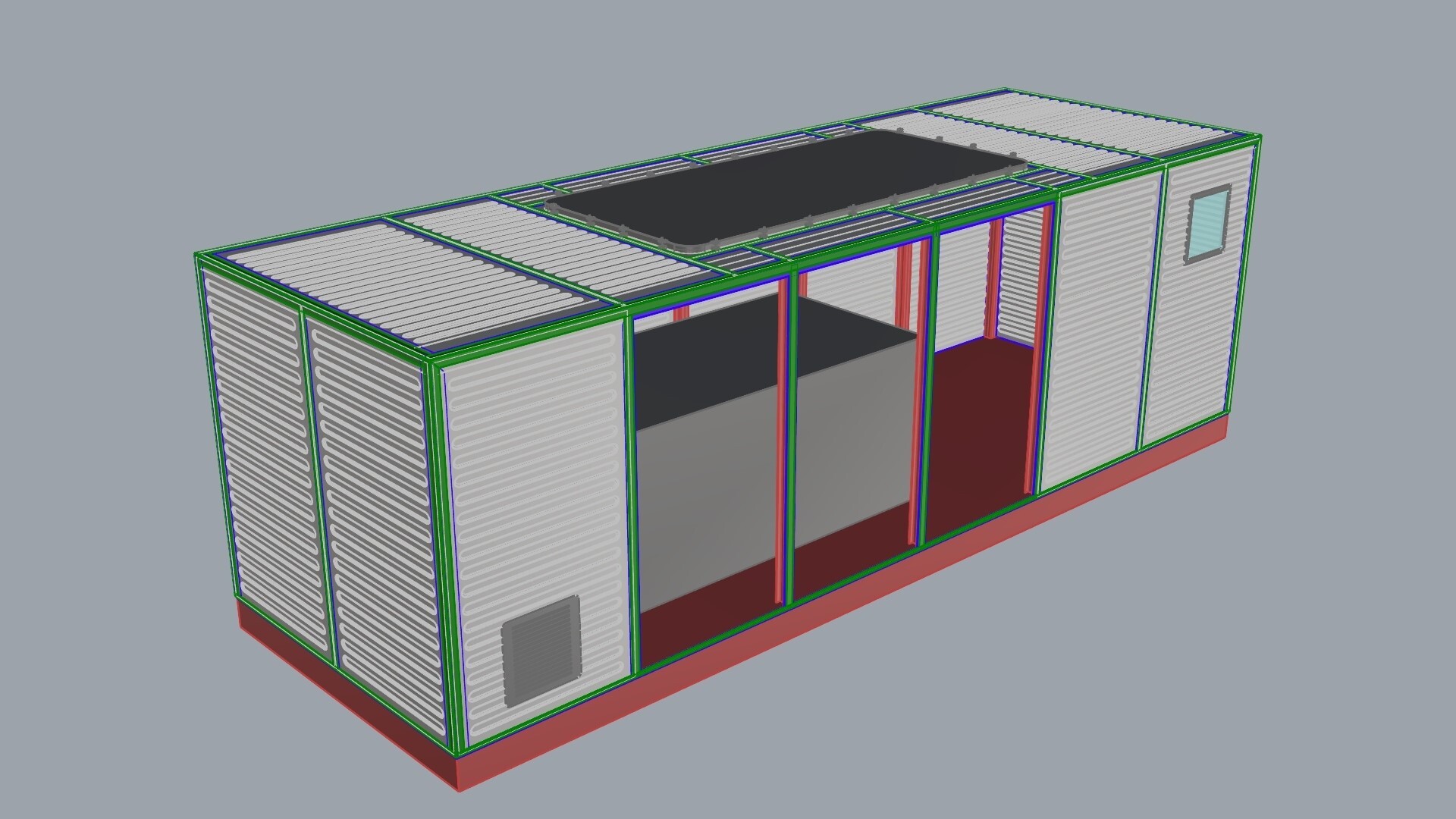

Together with aluminium construction specialist Bayards, Speira has developed a modular concept for nacelle cladding. Initial calculations show promising results:

"Our modular concept with aluminium not only brings ecological benefits but also shows that sustainability, efficiency and flexibility can go hand in hand," explains Herman Langerak at Bayards Aluminium Solutions.

The wind power industry is facing the challenge of combining an increasing demand for renewable energy with sustainable solutions. Aluminium offers one way to achieve these goals.

Pritzlaff emphasises, "Now is the time to actively drive material change in wind power. We want to add our materials expertise to the industry's technical learning curve. With aluminium, we are opening up a new dimension of sustainability."

Note: This press release, issued by Speira, is published as received without edits from AL Circle.

Image credit: Speira PR

Responses