您想继续阅读英文文章还

是切换到中文?

是切换到中文?

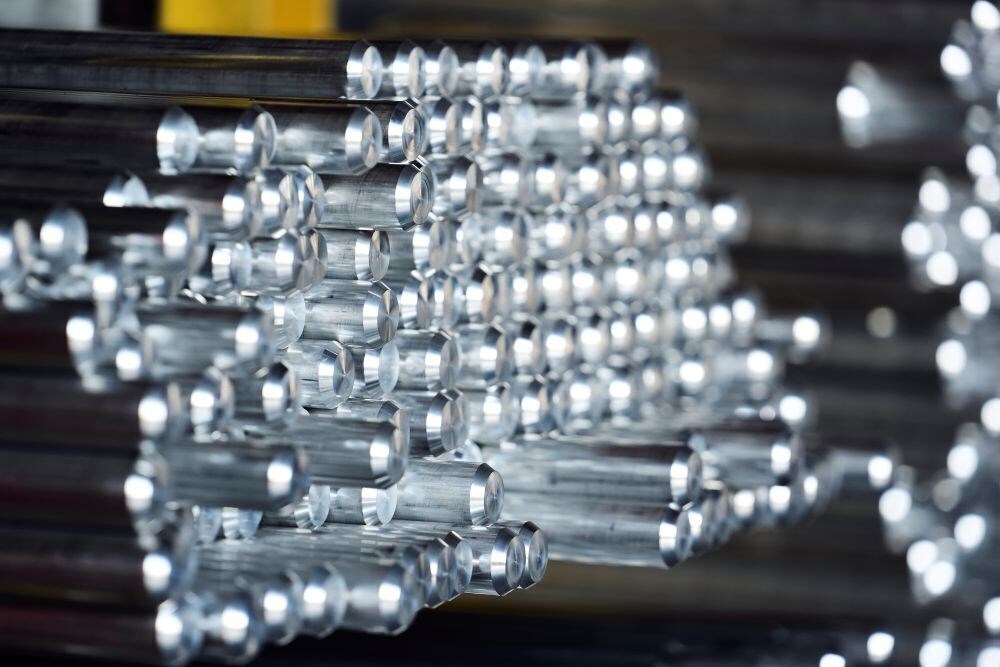

THINK ALUMINIUM THINK AL CIRCLE

Eural Gnutti - the world's leading manufacturer of drawn bars in aluminium alloys for mechanical processing and one of the major players in extruded bars and profiles - has subjected its 6026LF alloy to a series of laboratory tests to assess its possible use in applications in direct contact with food. The results significantly extend the potential applications of the alloy, already appreciated in the mechanical sector, to food production plants, including rollers and cosmetic packaging, in accordance with the latest European regulations on safety, health and sustainability of materials.

Explore- Most accurate data to drive business decisions with 50+ reports across the value chain

FROM BRAKES TO FOOD: THE 6026LF ALLOY BY EURAL SETS NEW PRODUCTION STANDARDS

Alloy 6026LF by EURAL, originally developed for vehicle braking systems and currently used in the automotive, pneumatics, electrical and electronic components and general mechanical sectors, stands out for its excellent machinability, high corrosion resistance and remarkable eco-compatibility. The absence of lead, combined with specific heat treatments, gives the alloy a highly sustainable and high-performance contour. Thanks to these properties, 6026LF by EURAL is a valid alternative for high-speed machining, compared to alloys traditionally used in the food and cosmetics industries, such as 6061, 6082 and 6063. In particular, it optimises processing times thanks to short chips forming in machining and achieves a better surface quality of the finished product, contributing to more efficient and environmentally friendly production.

In line with European regulations aimed at the progressive reduction of lead in materials and the protection of human health and the environment, the 6026LF alloy by EURAL is characterised by the almost total absence of lead, at a percentage equal to half of the permitted limits (Pb ≤ 0.05 per cent). This distinctive feature certifies its compliance with Delegated Regulation (EU) 2024 per197 (CLP) on the classification and harmonised labelling of hazardous substances, as well as with the REACH Regulation, which regulates the registration, evaluation, authorisation and restriction of chemicals. The alloy also complies with the requirements of the RoHS and ELV Directives, which limit the use of lead in electrical and electronic equipment and end-of-life vehicles, respectively.

Read More: VIVA launches 0.7mm aluminium louver system, targets 5 per cent share of India’s market

FROM SEM MICROSCOPY TO BISMUTH RELEASE: THE 6026LF ALLOY BY EURAL PASSED THE TESTS

To assess their suitability for food contact, several bars of 6026LF alloy by EURAL underwent in-depth instrumental analysis. The tests included microstructural characterisation, assessment of the corrosion resistance of the raw and anodised alloy, as well as specific tests on the migration of bismuth (Bi), present in the alloy in a concentration of less than 1per cent), in various aqueous simulants and the related toxicological analysis.

Specifically, observations using SEM (Scanning Electron Microscopy), EDS (Energy Dispersive Spectroscopy) and GD-OES (Glow Discharge Optical Emission Spectroscopy) analyses did not detect any traces of bismuth on the outer surface layers of the anodised bars. Corrosion resistance was confirmed through tests of electrochemical behaviour carried out on half-centimetre sections of bar, encapsulated in epoxy resin. These tests were conducted using a 595 ASTM aerated corrosion cell, with a 3.5 per cent by weight sodium chloride solution, continuously aerated with double purity air. The tests were performed both at room temperature and at 50 °C to simulate the typical operating conditions of food processing machinery.

The absence of passivation in the raw samples confirms the greater vulnerability of the untreated material to the action of corrosive agents, as the exposed surface does not develop a stable protective layer. On the contrary, in the anodised samples, marked passivation is observed, indicative of the formation of a uniform and protective oxide layer, capable of significantly limiting electrochemical degradation. The shift of the anodised curve at 50 °C, compared to that at room temperature, suggests how much the increase in temperature affects the stability of the passivation film, increasing susceptibility to corrosion even in anodised material. This data highlights the need to carefully evaluate operating conditions, especially in applications where the alloy is exposed to heat, in order to ensure maximum durability and safety of the material over time.

The bismuth migration tests, carried out in accordance with Regulation (EU) 10 per 2011 (MOCA), simulated the most critical conditions of prolonged contact between the raw 6026LF alloy by EURAL and foodstuffs. Exposed for 10 days at 60 °C in various simulant liquids - 3 per cent acetic acid, water, 10 per cent ethanol and oil - the samples showed visual alterations only in acetic acid and opacification in contact with water and ethanol, with no changes in oil. Further tests lasting 1 hour at 175 °C with an oily simulant and at 200 °C in modified polyphenylene oxide showed no significant release of bismuth, demonstrating the suitability of the alloy for high-temperature applications as well.

Must read: Key industry individuals share their thoughts on the hottest topics

BISMUTH IN 6026LF COMPLIES WITH EFSA STANDARDS

Finally, according to EFSA guidelines, toxicological assessment considers bismuth to be one of the heavy metals with the lowest risk profile, due to its low solubility and consequent limited systemic bioavailability. Currently available scientific evidence indicates that bismuth has no mutagenic or carcinogenic properties and no toxic effects on reproduction. Specifically, animal studies have shown that oral absorption of metallic bismuth is very limited (approximately 1%) and the systemic effects observed are minimal even at high doses. Furthermore, the impact on male fertility is not considered relevant for the risk assessment associated with oral exposure to bismuth compounds. Based on the most reliable and conservative toxicological data, a Tolerable Daily Intake (TDI) value of 0.08 mg per kg body weight per day has been calculated, in line with the FCA 2020 guidelines. For a 60 kg adult, this corresponds to a safe intake of 4.8 mg per day. Migration tests conducted on materials in contact with food revealed values below this limit, indicating the absence of critical issues related to the release of bismuth.

"The analyses conducted on the 6026LF alloy by EURAL show extremely encouraging results, confirming its innovative potential," says Giorgio Di Betta, Sales Director of Eural Gnutti, who concludes: "Thanks to its extraordinary workability, high performance and incredible versatility, the alloy, in addition to being widely used in the mechanical and automotive sectors, also opens up new opportunities in the food and cosmetic packaging sectors, thanks to its compliance with the latest European regulations on safety, health and sustainability of materials."

Note: This article has been issued by Eural and has been published by AL Circle with its original information without any modifications or edits to the core subject/data.

Responses