Amid growing concerns over its reliance on imported bauxite, China is quietly adjusting its industrial strategy. Several major aluminium producers are now turning to IB2, a French technology co-developed by entrepreneur Romain Girbal and chemist Yves Occello, to tap into the country’s vast but underused domestic bauxite reserves.

Image Source: Linkedin (https://www.linkedin.com/in/romaingirbal/)

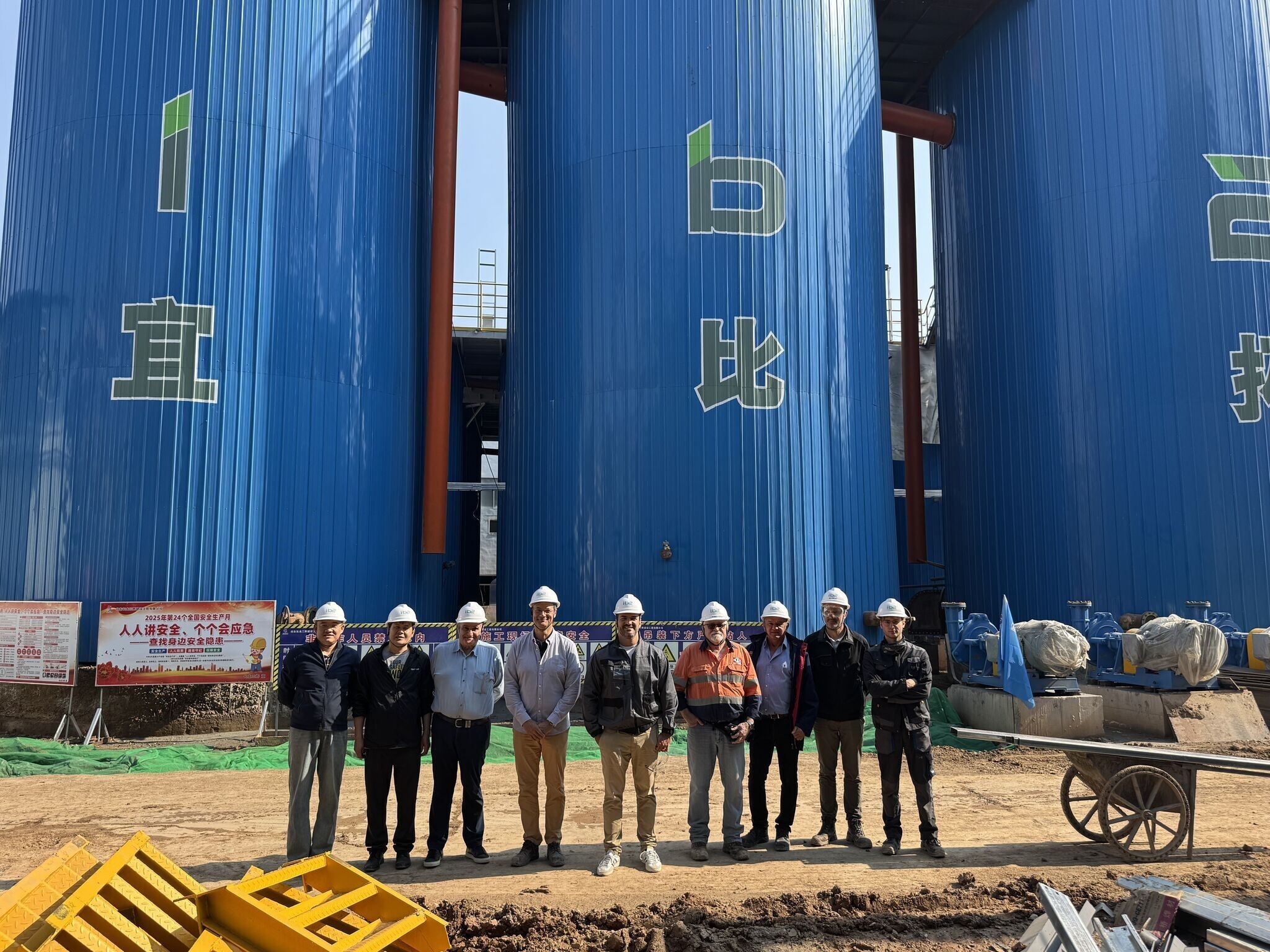

Image Source: Linkedin (https://www.linkedin.com/in/romaingirbal/)

The shift follows Beijing’s March release of its 2025-2027 roadmap for critical raw materials. One of its stated goals is to reduce reliance on imports, which currently account for more than 60 per cent of China’s bauxite supply, while significantly increasing the use of local ore. Recent permit cancellations in Guinea, China’s top supplier, have only heightened the urgency of this reorientation.

Turning overlooked ore into strategic feedstock

The IB2 process upgrades low-grade bauxite by selectively removing silica from kaolinite while preserving alumina. Local ores with alumina-to-silica (Al/Si) ratios as low as 2.5 can be transformed to around 11, well above conventional industry thresholds. When starting from higher grades ratios of 2.8 to 3, IB2 can push the output to 13 or 14.

Unlike conventional methods, IB2 integrates directly into existing refining infrastructure. This allows for rapid implementation, lower dependence on imported ore, and a meaningful reduction in transport-related emissions. “This is not just a technological breakthrough,” says Romain Girbal. “It’s a tool of industrial sovereignty. It enables China to produce smarter, cheaper, and closer to home.”

Industrial production begins this summer

The first full-scale IB2 facility is being completed in Shanxi province through a partnership with Liulin Senze Coal Aluminium. Production is set to begin this summer with an initial capacity of 600,000 tonnes per year, scaling up to 3 million tonnes annually with the same client.

The process also offers strong environmental advantages: 80 percent less caustic soda, 67 percent less red mud, and 40 percent lower CO₂ emissions. IB2 also produces tobermorite, a component used in low-carbon cement, aligning with China’s circular economy goals.

A French innovation at the heart of China’s industrial rethink

China’s adoption of IB2 highlights its industrial pragmatism and willingness to embrace strategic foreign innovation in pursuit of resource security. While the technology is also being considered in Saudi Arabia, Kazakhstan and India, its most significant impact is now unfolding in China, where geopolitical necessity meets technical efficiency.

Australia, too, presents a strong potential growth market for IB2, though it has remained under the radar until now. The next chapter in the global aluminium story may well begin here, powered by a French idea.

Note: This article has been issued by IB2 and has been published by AL Circle with its original information without any modifications or edits to the core subject/data.

Responses