您想继续阅读英文文章还

是切换到中文?

是切换到中文?

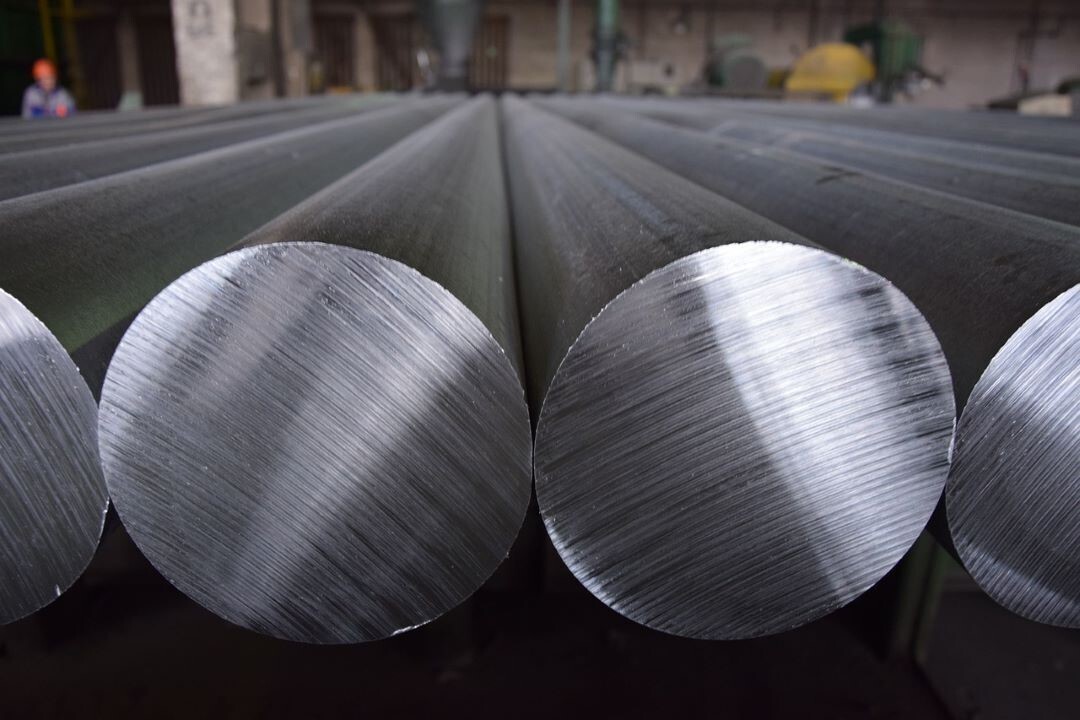

THINK ALUMINIUM THINK AL CIRCLE

The Aluminum Association today released a new white paper developed in collaboration with Wittsend Commodity Advisors, Powering Up American Aluminum: A Roadmap for Next Generation Supply Chain Resilience, outlining pathways to move the United States industry toward greater self-sufficiency in its domestic aluminium supply. The US aluminium industry has evolved over the last quarter century and shifted its business to become a global powerhouse in mid-and-downstream aluminium production and recycling – investing more than $10 billion in US operations over the past decade. At the same time, steady demand growth and a declining primary aluminium production footprint within the United States has led to a gap of around 4 million tonnes of raw (or unwrought) aluminium that the industry must import -- today largely from long-time trading partner Canada.

“Aluminium is a critical material for our nation’s economic and national security – found in everything from cars and cans to fighter jets, tanks and the electric grid,” said Charles Johnson, president & CEO of the Aluminum Association. “Even if we could flip a switch and turn on every idled aluminium smelter tomorrow, the US industry cannot currently produce nearly enough metal to make the products that Americans rely upon. This new research shows us that greater self-sufficiency will require an all-of-the-above approach to energy, trade and recycling policy to ensure that US manufacturers have abundant, affordable metal.”

Achieving US aluminium self-sufficiency will require time, money and commitment from both the public and private sector to build new smelters and recycle more aluminium. The white paper focuses on three main pathways to address industry metal supply:

Build new or restart idled primary aluminium smelters

Recover and recycle more domestic aluminium scrap

Import metal from trusted partners, especially Canada.

Enormous electricity requirements for primary aluminium production poses a unique challenge for industry self-sufficiency. A single new aluminium smelter uses ~11 TWh – a similar amount of electricity used by a major US city like Boston or Nashville each year. Furthermore, to be economically competitive, a smelter requires a 10 – 20 year contract with electricity costs ~$40/MWh. Technology companies are currently committing upward of $115/MWh for power at AI data centers. The Energy Information Administration estimates that the United States will have an energy deficit ~ 50 TWh by 2035 on current trendlines.

Consistent with the Trump administration’s vision to make the industry more self-sufficient and less reliant on imported metal, the Aluminum Association is calling on policymakers to support the Aluminium Agenda on areas like energy, trade and recycling policy to increase American self-reliance in this critical sector of the manufacturing economy.

Responses