ALUCOBOND®, a flagship brand of a Swiss major 3A Composites, which is a global innovator and a leading manufacturer of high-quality Aluminium Composite Materials, is set to further expand the footprint of its three-decade-old internationally recognized next-generation composite material ‘ALUCORE ®’ for Indian architecture applications.

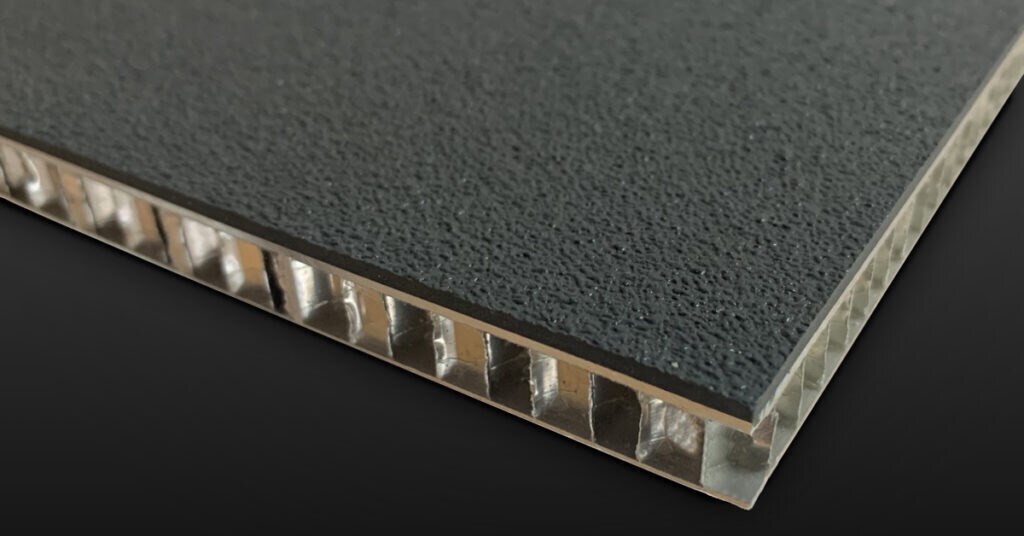

Building on its legacy, the product has been further advanced with cutting-edge technology and is now available in two innovative variants: ‘ALUCORE® Honeycomb Panels’ and ‘ALUCORE®ACCP’. As the name suggests, ALUCORE® Honeycomb features an aluminium honeycomb core sandwiched between two aluminium cover sheets, offering exceptional strength and durable lightweight performance. On the other hand, ALUCORE® ACCP incorporates an aluminium corrugated core between two aluminium skins, providing enhanced rigidity and versatility. Both variants are engineered to meet the evolving demands of Indian architects, enabling high-end, complex architectural designs with superior aesthetics and durability.

This expansion will boost its existing premier portfolio of technologically superior, new - age cladding solutions where design and performance play a crucial role. Such projects include high-end residential and commercial projects, airports and other mass–transit systems, stadiums, malls and multiplexes, to name a few. In India, ALUCORE® has been highly used in mega urban infrastructure and construction development projects such as Visakhapatnam Airport, Patna Airport, Lulu Mall in Lucknow, Max Towers in NOIDA, etc. With its high-mechanical properties, this product is suitable for applications like façade cladding, roofing, and even walkable roofs for maintenance.

Under the Prime Minister’s ambitious ‘Make in India’ mission, 3A Composites India Private Limited is manufacturing ALUCORE® at its state-of-the-art manufacturing facility at Ranjangaon near Pune in Maharashtra. Currently, ALUCORE® is widely rolled-out in India and exported globally, including to all leading markets within Asia Pacific and Middle East. Talking about this product’s legacy and wide applications, Mr Ranjeet Sharma, President and CEO of 3A Composites India Private Limited said, “In the rapidly evolving field of architecture, we are introducing path-breaking composite materials that redefine the industry. With ALUCORE®, we are empowering architects to design projects that prioritise performance, durability, and fire safety. Our unwavering commitment to innovation has earned us a significant reputation as the most reliable and quality-conscious supplier of metal cladding solutions, so we are confident that ALUCORE® will continue to be a game-changer in the Indian market, setting new benchmarks for architectural excellence."

Also read: India’s ACP market gets a new upgrade with Aludecor’s Mason Mark series

Explaining the enhanced focus on green building solutions within the ‘ALUCORE ®’ portfolio, Mr Amar Kirale, Associate Vice President, 3A Composites India Private Limited said, “ALUCORE® is 100% recyclable, making it one of thepromising façade materials for creating sustainable and intelligent buildings. We are expanding the outreach of ALUCORE® with the architects across India through experiential engagements and orientations. For the same, we have commenced an ambitious programme involving open-dialogues, direct sessions and presentations to showcase the strength of this product.”

ALUCORE® is manufactured on an automated intelligent production line, which ensures perfect flatness, finish and uniform quality. The product undergoes a multicoat, multi-bake process on a continuous industrial-grade coil-coating line, utilising the highest grade of fluorocarbon-based PVDF/FEVE paint system. The coating is done as per AAMA 2605 Superior Performance Specifications for exterior applications. All surface finishes of ALUCOBOND® are also possible with ALUCORE® such as solids, metallics, vibrants, wood-finish, stone-finish, marblelook, anodised look, etc. Moreover, 3A Composites also provides ‘Colour Customisation Service’ to match a specific shade for a particular project requirement in addition to the most sought - after RAL and PANTONE shades.

On the technical front, out of the two variants, ALUCORE® Honeycomb, in particular, stands out for its exceptional ‘Strength-to-Weight Ratio’ offering remarkable load-bearing capacity; yet remaining lightweight. This is made possible by the strategic placement of an extremely strong aluminium honeycomb core between two aluminium skins, effectively increasing the distance between them. This innovative design imparts remarkable rigidity, allowing the product to withstand high wind pressures and significantly enhancing the resilience and structural integrity of the facade. Built with a non-corrosive marine–grade alloy, ALUCORE® ensures long-lasting durability, superior weather resistance and reliable performance even in the most demanding environmental conditions.

Also, ALUCORE® meets the stringent Class A2-s1, d0 fire classification as per EN 31501-1 test standards to provide fire protection to building assets and human lives. This feature reinforces its suitability for high-rise buildings, critical infrastructures and spaces with heavy human traffic where fire safety standards are non-negotiable.

Launched globally in 1994, ALUCORE® has consistently gained wide acceptance among architects and façade consultants worldwide, with numerous landmark projects showcasing its performance and versatility. Among these, a major global milestone was reached in 2019 when China’s Beijing Daxing International Airport— designed by the world-renowned architect Zaha Hadid—incorporated approximately 6.5 lakh sq. ft. of ALUCORE® for roofing. This iconic project was executed using ALUCORE® CLAD, a value-added service by 3A Composites that provides ready-toinstall panels, fabricated at ALUCOBOND®’s advanced manufacturing facility. This ensures unmatched precision and finesse in the final installation.

In India, ALUCORE® continues to play a vital role in several upcoming mega projects, further strengthening its footprint in the architectural and infrastructure landscape.

On the other hand, as far as the Company’s flagship brand ALUCOBOND® is concerned, about 2.5 lakh sq. ft. of the material has been utilised as façade cladding in the construction of the newly inaugurated Navi Mumbai International Airport at Panvel near Mumbai, which has also been designed by architect Zaha Hadid.

Must read: Key industry individuals share their thoughts on the hottest topics

Note: This article has been issued by ALUCOBOND® and has been published by AL Circle with its original information without any modifications or edits to the core subject/data.

Responses