您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

The aluminium industry has long sold itself as the ‘metal of the future’, well known for being lightweight, infinitely recyclable, and indispensable for decarbonisation in transport, construction and packaging. Yet, when scrutinised from a life-cycle perspective, the path from bauxite to ingot reveals an environmental footprint that is both energy-heavy and highly variable depending on geography. A landmark cradle-to-gate life cycle assessment (LCA) conducted by the International Aluminium Institute (IAI) brings forth one blunt truth, i.e., electricity supply is the single biggest determinant of aluminium’s environmental impact.

Image source: https://www.researchgate.net/

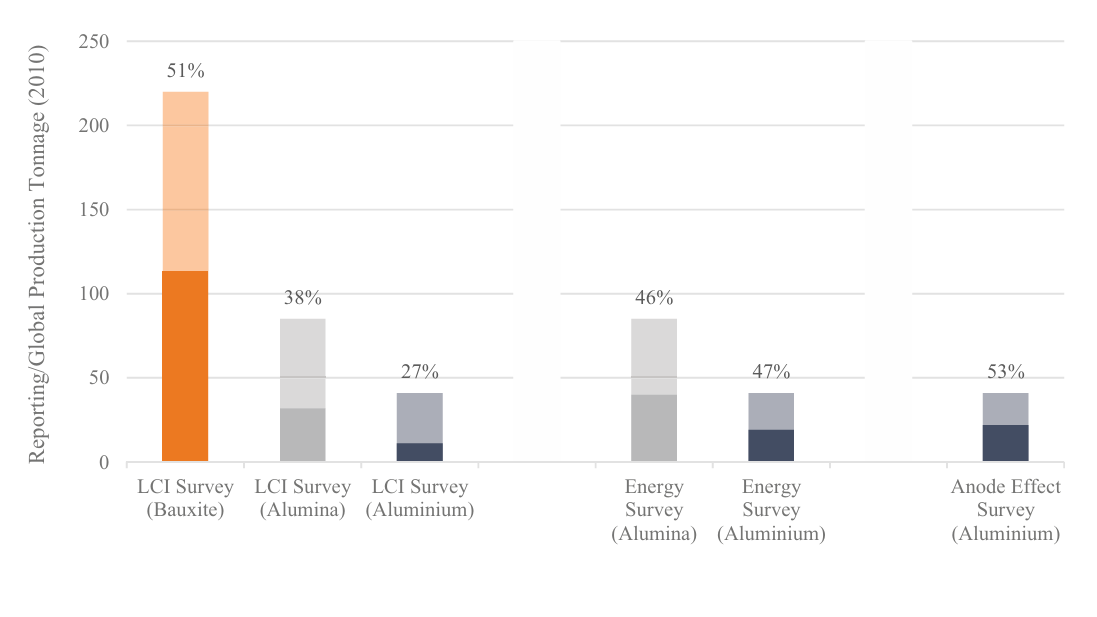

The study, built on IAI’s global survey data and modelled using GaBi software, measured six core impact categories that includes global warming potential, acidification, eutrophication, ozone depletion, fossil energy depletion, and photochemical smog creation, along with water scarcity. The results provided a global dataset (GLO) and a rest-of-world (RoW) dataset that excludes China, allowing the role of the world’s largest producer to be measured in stark relief.

The findings were unequivocal. Producing a single kilogram of primary aluminium generates 16.5 kg of CO₂-equivalent emissions globally, compared with 10.8 kg CO₂-equivalent in the RoW dataset. The gap is almost entirely explained by China’s earlier coal-reliant power system. Coal accounts for 51 per cent of the global electricity mix for smelting but just 23 per cent in the RoW dataset, while hydropower dominates elsewhere, making up 65 per cent of the RoW mix.

Electrolysis, the most energy-intensive step, emerges as the largest single contributor, accounting for 56 per cent of global greenhouse gas (GHG) emissions from cradle to gate. Alumina refining adds another 23 per cent. In both cases, the type of power plant behind the plug defines the scale of impact. Coal-fired grids double the GHG intensity of electrolysis: 9.2 kg CO₂ per kg Al in the global dataset versus 4.6 kg in the RoW model.

…and so much more!

SIGN UP / LOGINResponses