The chip melting furnace at the Kassel foundry, operational since June 2024, marks a major advancement in the recycling process. This innovative furnace is set to lower energy consumption by approximately 3,250 MWh annually, significantly cutting operating costs and minimising environmental impact. Moreover, it will reduce CO2 emissions by over 1,400 tonnes per year, substantially contributing to climate target achievements.

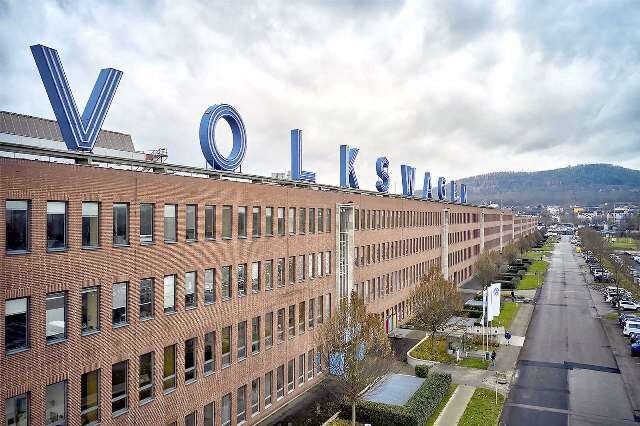

Image Source: Volkswagen AG Kassel plant

About the on-site melting process

Recycling all aluminium chips generated at the Kassel plant back into the casting process represents a key milestone in advancing circular economy practices and sustainability. This innovative on-site melting process significantly reduces energy consumption by approximately 3,250 MWh annually and lowers CO2 emissions by over 1,400 tonnes each year.

These initiatives align with Volkswagen's 'goTOzero' mission, which focuses on significantly reducing CO2 emissions in production while fostering sustainable and resource-efficient manufacturing practices. By adopting environmentally friendly technologies, the Kassel foundry is positioning itself as a leader in driving the transition toward a more sustainable industrial future.

Reduced transportation cost

Another benefit of this measure is the reduced truck traffic, as there is no longer a need to transport materials to external recycling companies. This lowers transportation costs and lessens the environmental impact by reducing traffic. In summary, this project demonstrates Volkswagen's proactive approach to adopting sustainable production practices at the Kassel plant while simultaneously boosting efficiency.

"By eliminating an additional external remelting process, we will remain more ecological and economical than before, despite the transportation routes to Kassel that will then be required," said Wöllenstein.

Image Source: Volkswagen AG Kassel plant

Goal of the company

Approximately 20 tonnes of aluminium chips are produced and melted at the Kassel plant daily. In the medium term, the foundry plans to process an additional 40 tonnes of material from other Volkswagen plants across Europe. Ultimately, the goal is to increase the volume to as much as 80 tonnes of chips.

Mirco Wöllenstein, the foundry manager in Kassel, highlights the significance of the decision to melt aluminium chips on such a large scale. Given the innovation and complexity of the process, he describes this move as both bold and groundbreaking. A key consideration is preventing corrosion, as any corrosion on the chips could compromise the quality of the melting process. Wöllenstein also underscores the importance of collaboration across various plants and business areas to achieve the highest possible CO2 savings. This reflects the Kassel foundry's dedication to improving efficiency and making a proactive contribution to reducing its environmental impact.

Responses