您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

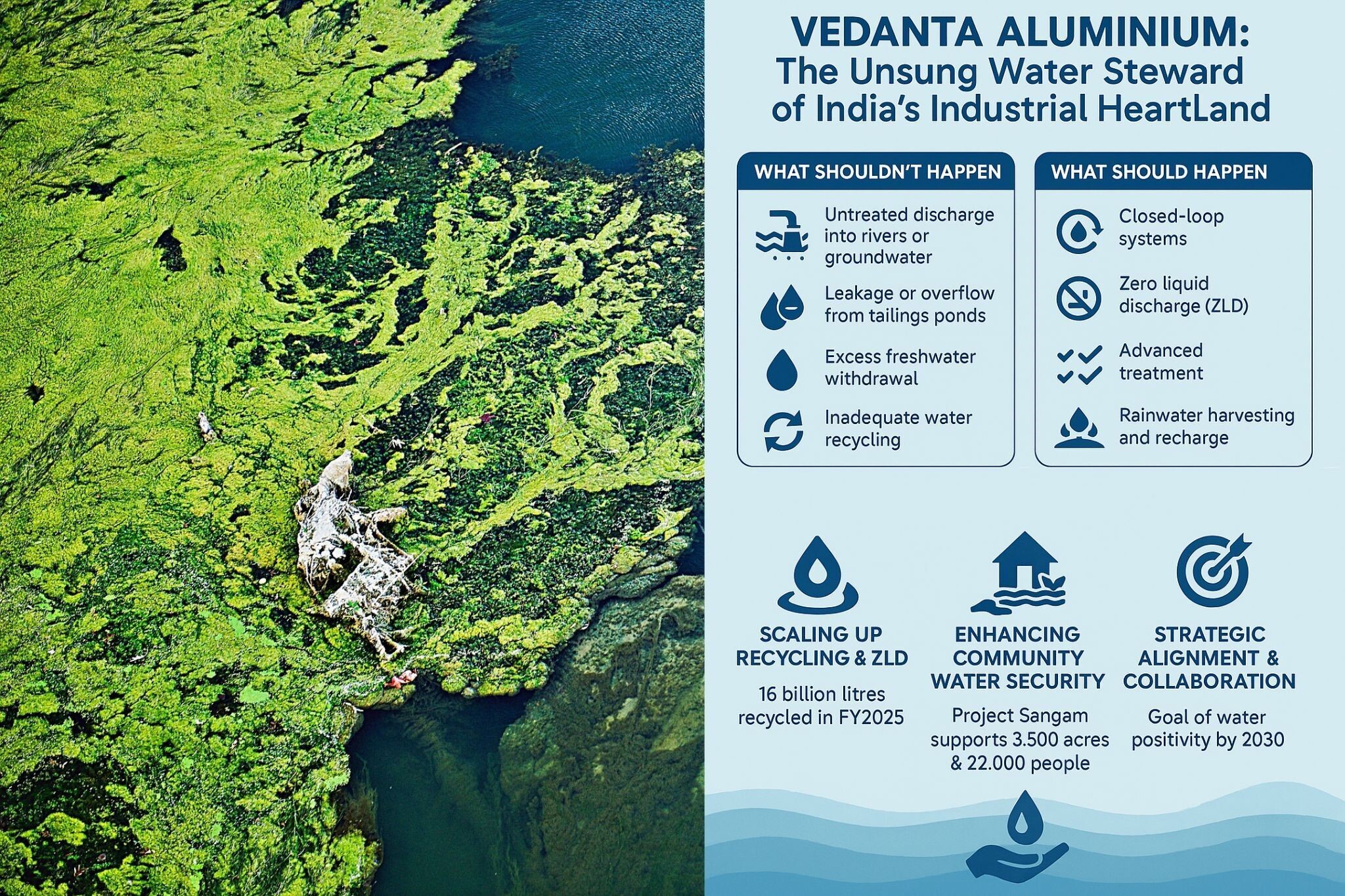

In a country where water scarcity is both a rural crisis and an industrial liability, few sectors are as thirsty and as scrutinised as the aluminium industry. With primary aluminium production requiring anywhere between 20,000 to 40,000 litres of water per tonne, efficient water use isn’t just an operational concern; it’s a socio-environmental imperative. While reliance on dated, extractive water systems and rudimentary discharge mechanisms usage remains a key focus area to work upon as an industry, Vedanta Aluminium has helmed sustainable operations with a narrative of an apt blend of recycling, zero-liquid discharge, and community water stewardship.

Image for representational purposes only

Image for representational purposes only

What typically happens to water in aluminium production

Water is integral across the aluminium value chain, from dust suppression during bauxite mining to digestion and cooling in alumina refining and then again in the smelting and casting stages. Unfortunately, during a major chunk of the period, for many industrial corridors across India and globally, water has been used linearly: draw, use, and discharge. Contaminated water, laden with caustic soda, red mud residues, or fluorides, may be stored in tailings ponds or released with inadequate treatment, risking groundwater contamination and environmental degradation. This model has historically clashed with agricultural communities that depend on the same freshwater sources in areas like Odisha and Chhattisgarh.

What shouldn’t happen is precisely this — the unchecked withdrawal of groundwater, untreated discharge into rivers or open lands, and poor wastewater management that leads to environmental hazards.

What should happen instead?

However, global production businesses have played a more responsible role in the aluminium circular economy for the past decade. The solution to water contamination, in order to achieve a lower carbon footprint and limited pollution aggravation, lies in a closed-loop system: recycle, treat, and replenish. Modern aluminium operations globally are adopting Zero Liquid Discharge (ZLD) models, wherein no wastewater leaves the facility untreated. Advanced treatment systems like Reverse Osmosis (RO), high-efficiency cooling towers, and dry stacking of red mud are becoming industry best practices. Water positivity, replenishing more water than consumed, is no longer just a buzzword; it’s a performance metric that investors and regulators alike demand.

…and so much more!

SIGN UP / LOGINResponses