The e-Magazine "ALuminium Casting Industry: Focus 2024" by AL Circle delves into the development of technology in the aluminium casting sector, shaping production methods, operational strategies, and overall industry standards. Digital transformation is one of the most trending words in the business community since 2020, and we generally get different explanations when asked about it by different people in different industries. Whenever there is a thought or a discussion on Industrial Automation, the work or framework of Industry 4.0 is the buzzword. Digitalisation or digital transformation is a journey with far-reaching timelines and results on the bottom line rather than being a project. Thus, the originators or the architects of the digital transformation journey must consider the big picture even before starting the project identification process.

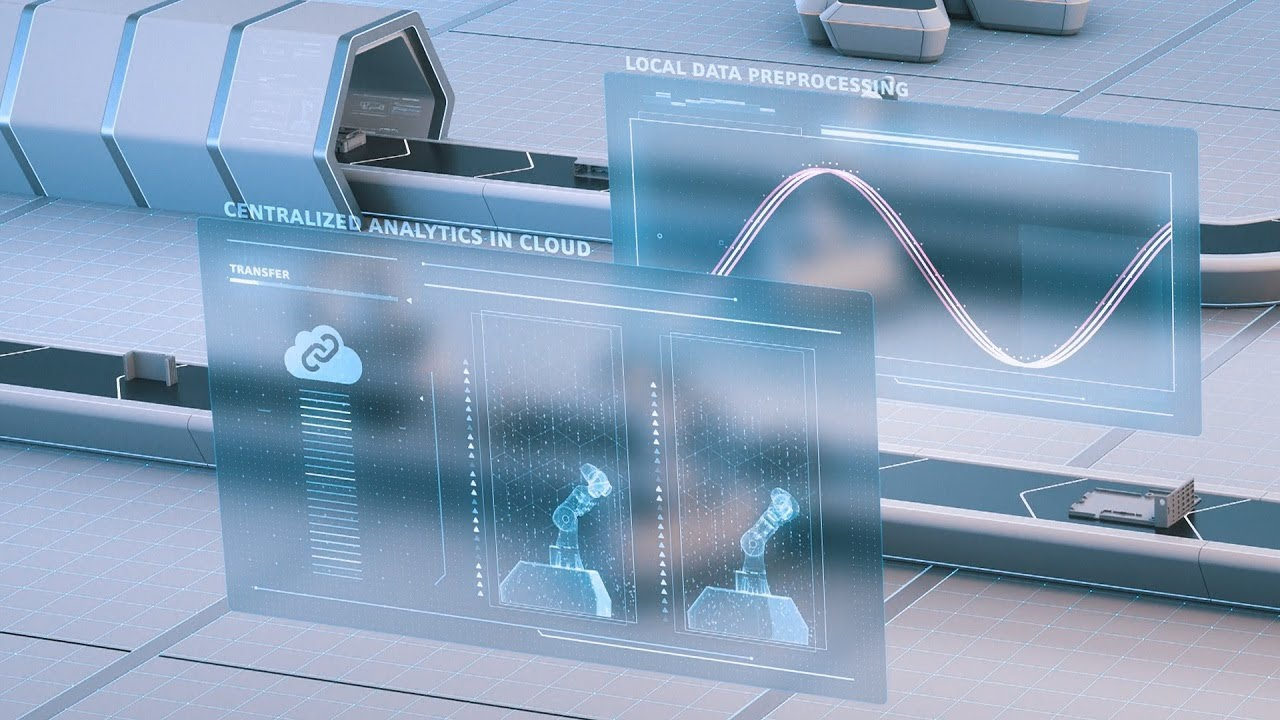

When delving into the casting Industry, it's crucial to integrate a combination of Industrial Internet of Things (IIoT), Enterprise Resource Planning (ERP), Cloud-based infrastructure for data analysis and regression, and Machine Learning (ML) as core components. These elements, along with inputs from Programmable Logic Controllers (PLCs), subject to approval from the Original Equipment Manufacturer (OEM), establish a resilient framework.

Distinguishing between automation and digital transformation is crucial in understanding their respective scopes and implications. Automation primarily focuses on streamlining processes, particularly repetitive tasks, by harnessing machinery and software to render them self-operating. This spectrum of automation encompasses low-cost Automation (LCA) initiatives and intricate automation endeavours, such as the deployment and programming of pick-and-place robots or optimising their operational pathways.

On the other hand, digital transformation involves a more comprehensive approach. It entails identifying and evaluating Critical to Quality (CTQ) and Critical to Machine Health (CTM) parameters, followed by developing strategies aimed at directly capturing these parameters from machinery. This may involve integrating Programmable Logic Controllers (PLCs) or retrofitting sensors to facilitate data acquisition. Digital Transformation seeks to leverage technological advancements to enhance operational efficiency, optimise performance, and drive strategic decision-making within an organisation.

The advent of Industry 4.0 brings about a profound transformation across the entire product lifecycle and supply chain, spanning from design and sales to inventory management, scheduling, quality control, engineering, and customer and field service. This revolution creates a collaborative ecosystem where stakeholders benefit from access to informed, real-time insights into production and business processes, enabling more comprehensive and timely analytics.

Case study: Toyota Industries & Siemens forge digital transformation partnership in die-casting

Toyota Industries Corporation and Siemens collaborated to pioneer the development of artificial intelligence (AI) to predict product irregularities in aluminium die casting, a critical aspect of automotive air conditioning compressor manufacturing. This groundbreaking endeavour marks one of the earliest instances of defect prediction AI in die casting, enhancing quality assurance and productivity. Leveraging this AI application within Industrial Edge, Siemens' edge computing platform is tailored for industrial settings and exemplifies an innovative approach to digital transformation in manufacturing.

Toyota Industries Corporation is a Japanese machine maker. Originally, and still actively, a manufacturer of automatic looms, it is the company from which Toyota Motor Corporation developed. It is the world's largest manufacturer of forklift trucks, as measured by its revenues.

Siemens AG is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability, and internationality for more than 170 years. Active around the world, the company focuses on intelligent infrastructure for buildings and distributed energy systems and on automation and digitalization in the process and manufacturing industries. Siemens brings together the digital and physical worlds to benefit customers and society.

Toyota Industries Corporation intends to leverage this advancement to refine its technology further, integrating it into its production facilities both domestically in Japan and internationally. Siemens anticipates broader adoption of their digitalisation and automation solutions, such as Industrial Edge, across the manufacturing sector. The die-casting process presents inherent challenges, with fluctuating production conditions like variations in molten aluminium temperature or injection rates. Traditional management relies heavily on the expertise of seasoned workers, often necessitating secondary processing to address irregularities and uphold stringent quality standards.

During their collaborative development efforts, the two companies utilised a Siemens Simatic S7-1500 controller to collect extensive data, totalling approximately 40,000 data points per die-casting shot on the production line. This data was then subjected to analysis through AI technology. Their efforts successfully prevented defects and enhanced quality by enabling real-time monitoring of production status and automatic prediction of equipment abnormalities that could compromise quality.

An AI system processes the production data for defect prediction on Industrial Edge, facilitating immediate analysis of production conditions at the time of casting and evaluation of part quality right after casting. This suite of AI technologies not only amplifies productivity but also enhances quality standards, revolutionising operators' operational procedures.

Aluminium die casting is a rapid moulding process where molten aluminium is injected into a die under high pressure, particularly suited for manufacturing metal cast parts with stringent dimensional precision. It is a preferred method for producing automotive components requiring exceptional quality and reliability. The aluminium die-cast parts manufactured at the Toyota Industries Corporation production facility in Obu, Japan, boast superior airtightness and resistance to high pressure. These components are indispensable for the top-tier compressors produced by Toyota Industries Corporation for automotive air conditioning systems, wherein they proudly dominate the global market share.

Conclusion

Various digitisation initiatives empower die-casting foundries to enhance operational efficiency in terms of cost and productivity. Additionally, by leveraging the gathered data, these foundries can unlock new avenues for business expansion.

In conclusion, the fusion of aluminium die casting with digital technology marks a transformative leap in manufacturing efficiency, precision, and sustainability. As industries embrace this innovative synergy, we embark on a new era of heightened productivity and boundless possibilities, shaping the future of manufacturing with unparalleled ingenuity and excellence.

Responses