AMALLOY, a patented new aluminium alloy powder created exclusively for additive manufacturing by the Technology Innovation Institute (TII), was unveiled at the AM Conclave conference in Abu Dhabi. AMALLOY is the Middle East's first metal additive manufacturing feedstock developed for laser beam powder bed fusion (PDF-LB) systems. The low-cost, high-strength aluminium alloy prints and performs very well.

Compared to commercially accessible AlSi10Mg alloys, AMALLOY exhibits a 33 per cent increase in strength while maintaining its ductility. The aforementioned characteristics render the newly developed material very suitable for applications that need both lightweight properties and strong power, making it an exceptional choice. AMALLOY has a very low sensitivity to hot cracking due to its chemical composition and inherent metallurgical compounds. Consequently, it allows for greater strength levels without encountering hot cracking problems.

{alcircleadd}

"Our focus is on developing high-strength alloys with excellent printability. We intend to use these new materials in manufacturing defect-free parts to be employed in critical and high-value applications. We are adopting a framework for an integrated computational and experimental approach to design and produce these new materials for use in metal AM. This framework constitutes six phases including alloy design, experimental validation, AM for in situ-alloying with accelerated process optimization, material testing, metal powder optimization, and finally, documentation," said Dr Nesma Aboulkhair, Director of Additive Manufacturing at TII.

A strong co-eutectic microstructure coupled with high saturation, precipitation hardening, and grain refinement allows for higher strengths. Atom Probe Tomography (APT) investigations in partnership with Oxford University indicated the presence of nano-precipitates in the primary aluminium microstructure, increasing the alloy's strength. Furthermore, the alloy has undergone testing at temperatures reaching 300ºC, demonstrating exceptional thermal stability. This characteristic renders this particular grade potentially suitable for use in high-temperature situations.

The framework is used internally throughout the whole process. It has already shown significant success in the development of AMALLOY, prompting TII to submit a patent application for the alloy to the US Patent Office. TII aims to use the framework to create novel alloys derived from different families of metals. Additionally, TII anticipates using the adaptable framework to generate new alloys suitable for conventional production procedures.

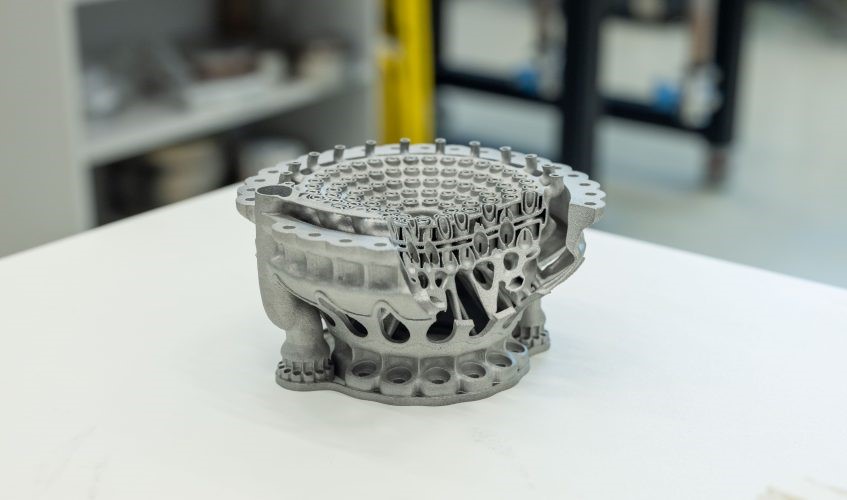

"The target clientele for the new material we are developing for metal 3D printing are worldwide metal powder producers and we are exploring licensing our new patented alloy compositions to global manufacturers. Some of the use cases that the specific AMALLOY is suitable for include low buy-to-fly parts for aerospace/aviation [i.e., antennas, aircraft brackets, nanosatellites] and high strength components such as topology optimized engine brackets," added Dr Federico Bosio, Lead Researcher for Additive Manufacturing Materials at TII.

AMALLOY exhibits a diverse array of notable material qualities in its original printed form. These characteristics include an exceptional relative density of 99.9 per cent or over, guaranteeing its structural integrity and strength. Furthermore, it has a low sensitivity to hot cracking, as shown by an HCS coefficient below 0.3 according to the Clyne and Davis model, improving its durability throughout manufacturing procedures. AMALLOY has a Vickers hardness range of 140 HV to 200 HV, attributed to its distinctive chemical composition. The mechanical performance of this alloy is noteworthy, as seen by its yield strength ranging from 200 to 350, which is governed by its chemical composition. Additionally, it exhibits an ultimate tensile strength ranging from 350 MPa to 500 MPa, further confirming its appropriateness for a wide range of applications.

Responses