您想继续阅读英文文章还

是切换到中文?

是切换到中文?

THINK ALUMINIUM THINK AL CIRCLE

Introduction

The need to measure dissolved hydrogen in aluminium alloys has never been greater as the quality specifications demanded by end-users continue to increase.

{alcircleadd}Methods of measuring hydrogen have been commercially available for many years, but the performance of these methods has generally not kept pace with industry requirements for fast, accurate, reliable, and cost-effective measurements in real-time. In addition, these methods do not readily lend themselves to the ever-increasing demands for automation and traceability through the integration of measured hydrogen results into existing computerised customer quality assurance systems.

EMC Limited has developed a new hydrogen determination method, HycalTM, based on an electrochemical sensor that fulfils all the current industry needs for a hydrogen measurement device in terms of performance and cost-effectiveness. In addition, it provides the functionality that offers the possibility of automating the measurement and integrating the results into customer quality assurance systems, giving full traceability, and enabling much greater control of dissolved hydrogen than has been possible before today.

Sensor technology

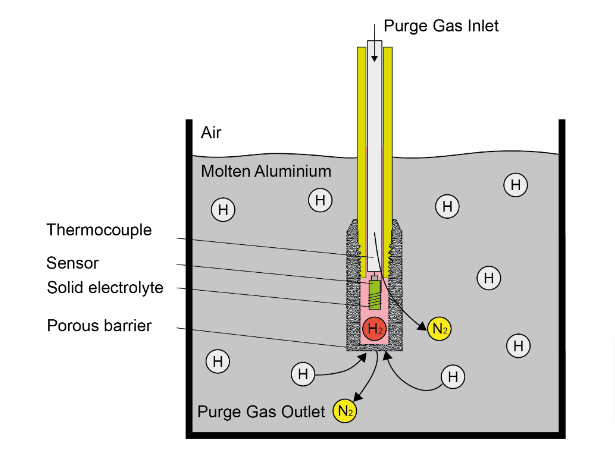

The principle of operation of Hycal is electrochemical and is based upon an electrochemical cell that responds to the presence of hydrogen by generating a small electrical voltage. The voltage generated depends on the ratio of the unknown hydrogen concentration being measured to a known hydrogen concentration within the cell reference material. If certain other variables are known, then the precise concentration of dissolved hydrogen present in the aluminium can be calculated.

To enable this electrochemical system to function in liquid aluminium, the sensor is enclosed in a chamber within the end of the metal and ceramic probe. It is separated from the aluminium by a porous diffusion barrier. When the probe is placed in the aluminium, the hydrogen dissolved in the melt diffuses through the porous membrane and forms hydrogen gas within the chamber in which the sensor sits. The voltage generated by the cell is then measured and taken to an analyser using a flexible cable. By taking into account several variables, such as melt temperature and alloy composition, the level of dissolved hydrogen in the melt can then be quickly and accurately determined. Once calculated, the analyser continuously displays and records the hydrogen value and melt temperature.

Figure 1 – Measurement Schematic

The longevity of the probe is typically 100 measurements or 20 hours of continuous immersion which gives a significantly lower operating cost compared to other commercially available systems.

Analysers

A range of different designs of analysers are available to meet various customer needs and budgets. The unit most widely adopted by our customers today is the Hycal Mk4, and a description of this unit will illustrate the technology's capabilities.

Figure 2 – Hycal Mk4

Hycal Mk4 is a portable analyser easily operated by shop floor personnel. Its low weight, compact size, and integrated probe holder mean it can be used for spot measurements in various locations, from melting furnaces to casting stations. It has a “guided measurement” function, which takes the operator step by step through the measurement process, thus ensuring that all the necessary parameters for an accurate reading and later traceability of the results are entered into the analyser via a touch screen. The unit is battery-powered and has an internal gas cylinder, meaning that, if required, it can be operated autonomously without any external connections. The external supply of power and inert gas is also provided.

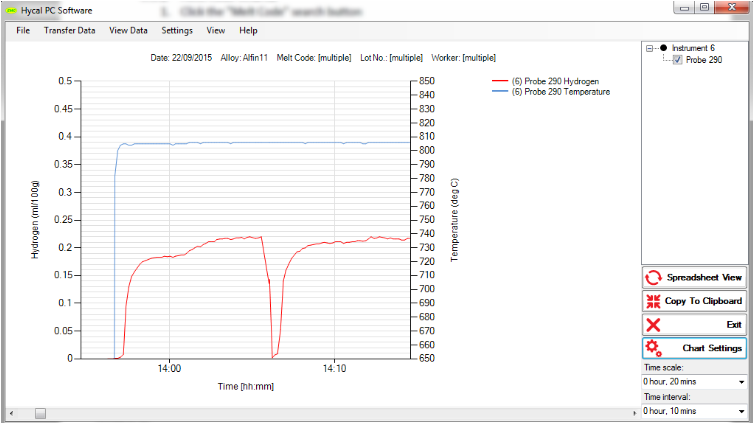

The time needed to obtain a stable measurement is typically 5 minutes. Once the reading has stabilised, the probe will continue to measure and respond to any hydrogen concentration changes in under 5 seconds. The results can be visualised and recorded in several ways. The touch screen can display simply numeric values of hydrogen content and temperature or a real-time graph charting hydrogen and temperature against time. In both these modes, hydrogen content and temperature are displayed in real-time.

The analyser automatically records hydrogen concentration and temperature and can later be downloaded via a USB port. A PC software program is available to manage and chart results as required. Alternatively, the results can be downloaded directly to external computer systems via an Ethernet port. More detail on this is given later.

Figure 3 – PC Software Output

Automation

A second analyser design, Hycal 1000, has all the functionality of Hycal Mk4 but with the added features of networking and automation. It is intended as a fixed installation where regular measurements at one location are required.

Hydrogen measurements can be automated by mounting the Probe on a vertical actuator. The actuator has four positions: Home, where the Probe is safely stationed when measurements are not required; above the metal prior to measurement; Probe In, where the Probe is immersed to take the measurement; and Change, where the Probe is accessible for replacement. All actuator functions can be programmed and controlled remotely to take measurements at set intervals or specific times during a cast.

Figure 4 – Probe Actuator

Figure 5 – Probe Actuator Control Panel

Networking

The majority of Hycal analysers are equipped with digital communications capabilities. They can be fitted with a protocol converter to facilitate rapid integration with an existing PLC network. The most common converters are Profinet for Siemens PLCs and EtherNet/IP for Allen-Bradley, but others are available upon request. The converter is supplied pre-configured and complete with the necessary configuration file (GSD for TIA Portal, EDS for RSLinx) and register map. The setup process is usually complete within a few minutes. After establishing the comms link, the PLC can completely control the Hycal measurement, optimising measurement integrity & probe life and eliminating operator error.

Summary

Hycal analysers offer fast, accurate and reliable hydrogen measurements. Automation and networking capabilities mean they can be used in a variety of applications and easily integrated into existing process monitoring and control systems to give full traceability, thus enabling much greater control of dissolved hydrogen than has been possible before today.

Responses