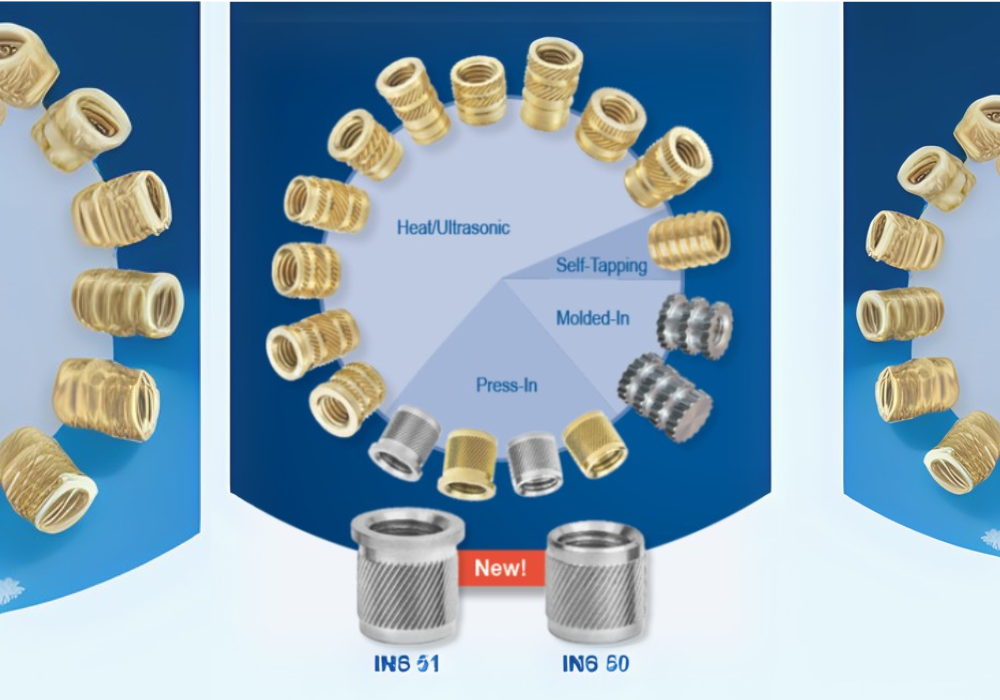

SPIROL has expanded its range of aluminium press-in inserts by introducing new options made from 2024 aluminium. These additions, available in symmetrical (INS 50) and headed (INS 51) versions, complement the company's existing line of brass inserts.

Image Source: SPIROL

Threaded inserts are critical in strengthening plastic components and providing durable, reusable threads in bolted assemblies. They help maintain consistent seating torque and prevent plastic creep over time, which can otherwise undermine assembly integrity.

Engineered for optimal performance and cost-efficiency, SPIROL's inserts come in various styles to suit different installation methods and application demands. The INS 50 and INS 51 series are designed for cold press-in installation, eliminating the need for heat and reducing overall installation costs while still delivering reliable joint performance for many use cases.

While brass remains the standard in machining due to its well-known material properties, 2024 aluminium offers a significant weight advantage. As a lead-free alloy, it also aligns with growing environmental and safety regulations. The differing galvanic properties of aluminium versus brass further expand application flexibility, offering engineers more options based on performance and compatibility needs.

Because the choice of the insert can significantly influence both the function and total cost of an assembly, SPIROL's engineering team is available to assist in selecting the ideal solution tailored to specific project requirements.

Responses