Bauxite and alumina can be considered as one of the most essential parts of Western Australia’s mining industry, underpinning the production of aluminium used worldwide in transport, infrastructure, and packaging. As one of the State’s most vital commodities, the sector is also closely monitored for worker safety, with new data shedding light on injury rates across major mining operations.

Image Source: South32 website

As per the WorkSafe WA data by The West Australian, bauxite and alumina recorded the highest injury rate among the State’s major commodities over two years, with Nickel bagging the second spot (recording 7.51 injuries per million hours worked, followed by iron ore at 5.14 and gold at 4.98). But the recent data shows a different picture altogether.

South32 achieves 60% REDUCTION in injury rates

“Worsley Alumina has achieved a sustained reduction in serious injuries from high-potential events and maintained that improvement year on year since introducing our Safety Improvement Plan (in 2022),” added the spokesperson.

The industry is dominated by Alcoa and South32, which process bauxite into alumina as the precursor to aluminium production. A South32 spokesperson noted that the company is recording “positive trends” in safety, with Worsley Alumina’s total recordable injury frequency rate improving from 7.1 in 2022 to 5.8 in 2025.

“While we are encouraged by an improvement in our safety performance metrics in FY25, particularly a 60 per cent reduction in high-potential injury and illness frequency, we remain focused on shaping a culture that is safety-focused, high-performing and values-based,” said the company.

Image Source - South32 report

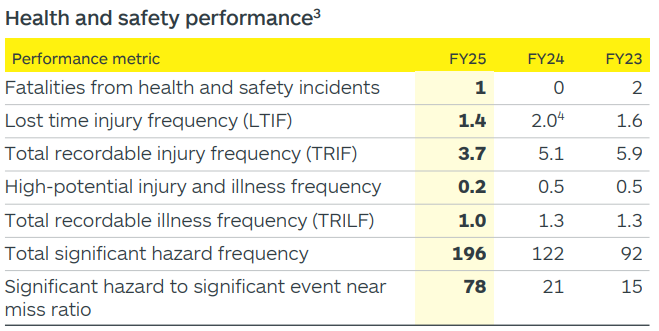

In FY25, the company achieved a 60 per cent reduction in high-potential injury and illness frequency, while both TRIF and LTIF declined by more than 25 per cent. These year-on-year improvements reflect South32’s sustained commitment to injury and illness prevention through targeted risk reduction initiatives and disciplined operating practices.

Metrics such as significant hazard frequency and the ratio of significant hazards to significant-event near misses demonstrate how effectively the company is identifying and mitigating safety risks before they cause harm. Their continued improvement in FY25 indicates stronger overall hazard management.

Also Read: Indonesia’s alumina surge puts heat on Australia’s South32

Targeted measures taken by Worsley Alumina

“The sector’s most common types of injury are over-strenuous movement, followed by contact with chemicals and slips/trips. In addition to our focus on fatality prevention, we are targeting the main types of injuries we see, which include musculoskeletal and chemical exposure. Our latest data shows our work is helping to reduce injuries,” said the spokesperson.

Worsley Alumina introduced a new four-week course designed to equip health and safety representatives with the skills and confidence to champion the company’s ‘safety guarantee’. Through the Health and Safety Representative Experience Program, participants work closely with specialist safety and training teams to enhance their hazard identification and risk assessment capabilities. The program also builds competence in leading safety inspections and strengthens knowledge of workplace inspection and incident investigation techniques. On returning to their roles, participants are better positioned to drive safety improvements within their teams and across the operation.

From July 2022 to September 2024, the bauxite and alumina reported an average of 9.49 injuries per million hours worked, significantly higher than the 3.24 rate recorded for tin, tantalum and lithium. As per the Chamber of Minerals and Energy WA, Western Australia produces about 67 per cent of Australia’s alumina, with its operations ranking among the most cost-efficient in the world. Over the two years, mechanical fitters at Nickel accounted for the largest share of injured workers with 524 cases, closely followed by processing plant roles with 521, and surface driving roles with 293.

Get industry insights from - A Comprehensive Analysis of Bauxite Residue - Red Mud

Responses