Performances of the Aluminium Industry are stressed not only to increase productivity while reducing costs, but also to improve environmental protection and preservation.

Reduction of carbon footprint across the entire Aluminium production the chain is, therefore, a binding demand to the metal producers.

{alcircleadd}Efficiency improvement in the metal production process well answers the demand to reduce production costs while at the same time protecting and preserving the environment.

Recent reports are showing a decrease in the carbon intensity of the Primary Aluminium Production. Europe is leading the ranks in the decrease of the carbon footprint of its primary production. Several projects and studies are focused to reduce the emission of CO2 and greenhouse gases, being a major challenge for the future of Aluminium production.

Nevertheless, the higher global average of carbon intensity in the primary Aluminium production, as well as picks in local countries (as China), highlights the needs to continue actions to decrease environmental impacts as all major Aluminium producers seem keen to reach.

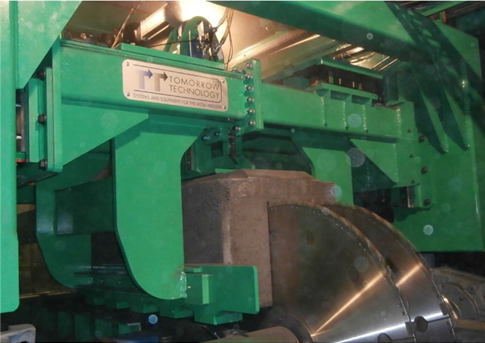

Fig 1 Tomorrow Technology Automatic Anodes Slotting Machine

Slotted Anodes Technology

Slotted anodes have been used by smelters that require large size anodes. Being inter-anode separations, slots can be considered acting as expansion gaps to safely absorb the heat-induced expansions. The slots are helping to reduce the thermal stresses in the anodes and thus reducing the risk of cracking.

Approach to slots cut in the bottom surface of the anodes is nowadays changed and becomes extremely important since they represent effective ways to escape gas continuously formed during Aluminium reduction process. As a direct consequence, the use of slots in the anodes allows to reduce electrical cell resistance as well as to improve cell stability. Slots in the anodes, therefore, result in reduced electrical power consumption for the Aluminium production.

Slots are preferably cut by automatic anodes slotting machines in the baked anodes (resulting in more effective than forming them at the green phase of the carbon block before baking, due to density, quality and scrap increase issues).

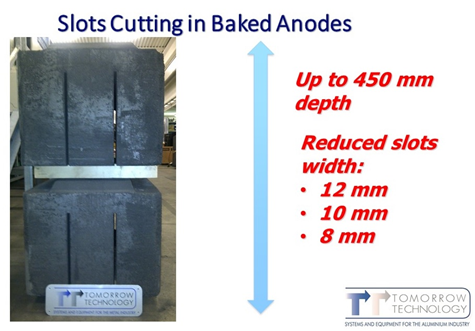

Slots are cut in automatic mode in each anode by rotating blades at depth up to 450 mm having a thickness as thin as 12,10 and 8 mm, with variable shapes.

The depth of the slots is important to ensure that benefits last throughout the entire life of the anodes (“full-life slots”), while slot shape, which determines the gas escape direction and related areas of influence, is also important to achieve further benefits in pot management.

Cutting slots with reduced width reduces the amount of carbon removed from anodes. Narrow slots are therefore improving specific Aluminium production per anode as well as prolonging anodes cycle time.

Slots cut in baked anodes

T.T. Tomorrow Technology -the Engineering and manufacturing Company based in Italy- has achieved particular knowledge in anodes cutting/slotting technology. The latest generation of Automatic Anodes Slots Cutting Machines confirms references and values of the major operational benefits coming from the use of slotted anodes in Aluminium reduction process. The main advantages obtained by the implementation of slotted anodes in the electrolysis cells are:

The related major benefits achieved by the use of slotted anodes with a direct impact on the Aluminium smelter economics are:

The latest generation of Anodes Slotting Machines operate to cut slots up to 450 mm depth with blades the thickness of 12 mm, 10 mm and 8 mm. Since the weight of carbon lost when anodes are slotted depends on blade thickness, the impact on cells performance and management is considerably in favour of slots cut with thinner blades which reduce the carbon lost while slotting the anodes.

FIG.2: Narrow and deep slots are cut in baked anodes with latest generation of Slotting Machine

The Two-Axis Dynamic Slot Cutting (TADSC) -patented by T.T. Tomorrow Technology- applied to the Automatic Slots Cutting Machine allows cutting different slot profiles, to reach the required preferential direction of gas escape and related benefits in pot management.

Particular considerations apply to conditions of interrupted slots in the pot with gas exit direction toward the centre of the pot.

As it is well known, alumina is fed into the bath during cell operation and it is important to have good alumina dissolution. The anode gas released during electrolysis can be used to create turbulence in the alumina feeding zone to help its dissolution and to reduce alumina agglomeration.

Interrupted slots are mean to facilitate gas bubbles movement rapidly to the centreline of the reduction cell to expedite dissolution of alumina.

For the above reasons the interrupted slots are cut in the anodes in such a manner as to direct flow gas to the centreline of the reduction cell to expedite the dissolution of alumina. Facilitating the gas flow toward the centre of the reduction, the cell gives operation advantages while increasing efficiencies.

In addition to the economic benefits of the increased Aluminium production - directly resulting from the reduced ACD distance-, Smelters using Anodes Slots Cutting Machines are confirming that the slots give also the following operation improvements:

Future scenario in the application of anodes slotting technology

Implementations of Anodes Slotting project represent investments with short paybacks. With the latest generation of Anodes Slotting Machines, it is now possible to cut slots in baked anodes up to 450 mm depth with 8 mm width only.

The trend toward a sustainable Aluminium production reducing Emissions of CO2 per tonne of Aluminium via optimising the operation practices and the process control for cells is on the path of the anodes slotting technology.

Aluminium smelters in Europe and worldwide with the more attractive and energy-saving process, reduces the environmental impact of their operations, improve their efficiency and profitability and contribute at the same time to the sustainable development of industries and materials.

FIG.3: Latest generation of Automatic Anodes Slotting Machine in operation while cutting slots 450 mm height and 8 mm width

Several calculations of the Return of Investment and of the payback period of the investments for new Anodes Slotting Machines to replaces former slotting equipment (even if still in working conditions) give evidence of the high profitability of the choice to upgrade or renew old equipment.

FIG. 4: Slotted anodes at end of life and before being put in operation

Conclusions

Short payback quickly starts after short delivery time and smooth implementation where the latest generation of Automatic Anodes Slotting Machines manufactured by T.T. Tomorrow Technology are in operation.

Slots are successfully cut in baked anodes up to 450 mm depth and 12, 10 or 8 mm in width.

In addition to the very high economic benefits of increased Aluminium production, smelters using Anodes Slots Cutting Machines are gaining further operational advantages.

We can conclude that the implementation of anode slotting technology allows paybacks ranging within short periods, even for smelters with smaller production capacity. It results in increased production capacity and minimizes production costs; while paying importance to safeguard energy resources, it leads to reducing environmental impact.

Responses