Aluminium is increasingly being used in additive manufacturing due to its unique properties and benefits in the production of high-performance components. Ricoh, a leading technology company has recently announced its innovative Binder Jetting Technology (BJT), which aims to revolutionise the production of end-use metal parts using 3D printing technology.

To maximise the efficiency of its aluminium BJT technology, Ricoh has partnered with Siemens Digital Industries Software and its Additive Manufacturing Network capabilities for production preparation, planning, scheduling, and production management.

This collaboration will enable Ricoh and its future users to assess designs, optimise critical properties, manage digital inventories, manage quotes, and track orders while also being able to analyse costs and scheduling.

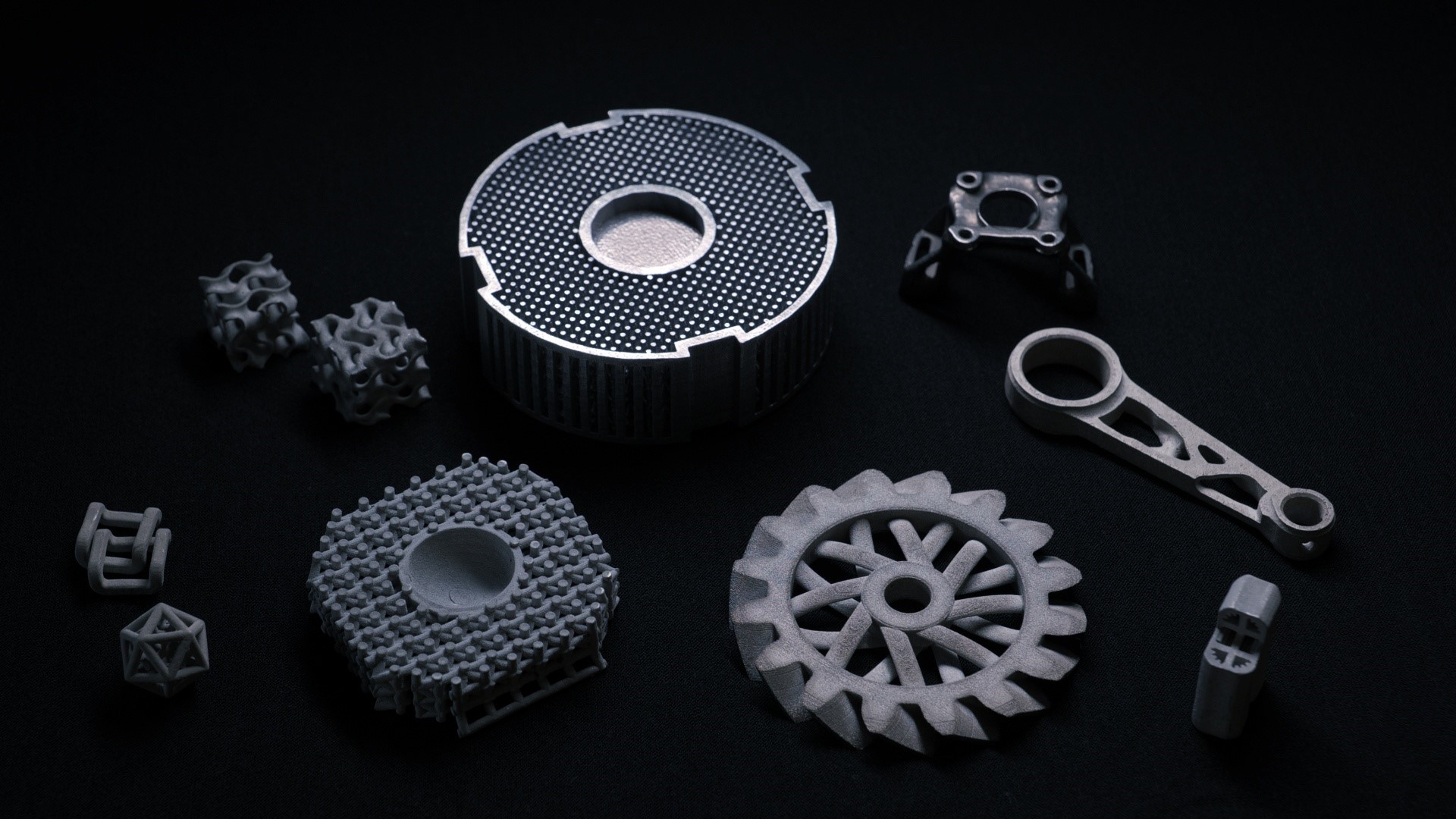

The BJT technology leverages Ricoh's inkjet printing technology to spread aluminium alloy powder over the modelling area and solidify it with a specially formulated binder to shape the part. After building the part layer-by-layer, the green part is sintered in a furnace to create a densified, end-use component that can be used as is unless other downstream processes are required.

The workflow optimisation will be supported by Siemens' Additive Manufacturing Network online order-to-delivery collaboration platform, while its Brownfield Connectivity offering will help Ricoh collect and store process information for quality stabilisation and production control.

The Senior Vice President of Digital Manufacturing Software, Siemens Digital Industries Software, Zvi Feuer, stated: "The production of aluminium parts is a holy grail for the additive industry, and we're delighted that Ricoh has chosen Siemens' Additive Manufacturing Network capabilities from the Siemens Xcelerator portfolio of industry software to help them commercialise a much sought-after process,"

"Our collaboration with Ricoh will apply its expertise in additive manufacturing with our knowledge and experience in delivering additive-specific operations management technology across a wide spectrum of industries – from order capture, production planning, and manufacturing to part delivery transaction closure. Together, Siemens and Ricoh are working to deliver repeatability and consistency at the scale needed to truly take advantage of using robust and repeatable aluminium additively manufactured parts in the commercial world," Feuer added.

The General Manager of Additive Manufacturing Business Center, Ricoh Futures Business Unit, Ricoh Company, Ltd., Tokutaro Fukushima, declared: "Ricoh will enable our customers to manufacture innovative aluminium components that have never been produced before by any process and will work with them to realise new customer value in the area of electrification of EVs and other forms of mobility. By combining Siemens' powerful solutions and knowledge with Ricoh's aluminium BJT, we will be able to provide our customers with highly reliable and practical systems for mass production applications. We hope to promote electrification together with our customers and contribute to solving social issues such as realising a zero-carbon society."

Overall, the use of aluminium in additive manufacturing is proving to be a game-changer, and Ricoh's innovative BJT technology, supported by Siemens' Additive Manufacturing Network capabilities, is set to provide a new level of efficiency in the production of end-use metal parts using 3D printing technology.

Responses