A team of Indian researchers from Shiv Nadar University in Delhi-NCR has developed a bioinspired aluminium surface with promising applications across marine engineering, food packaging, and healthcare. The study published in 'Colloids and Surfaces B: Biointerfaces,' demonstrated how nature-inspired designs (from the shape of lotus leaves to insect wings) can help produce multifunctional aluminium surfaces that are water-repellent, corrosion-resistant, antibacterial, and self-cleaning with minimal water use.

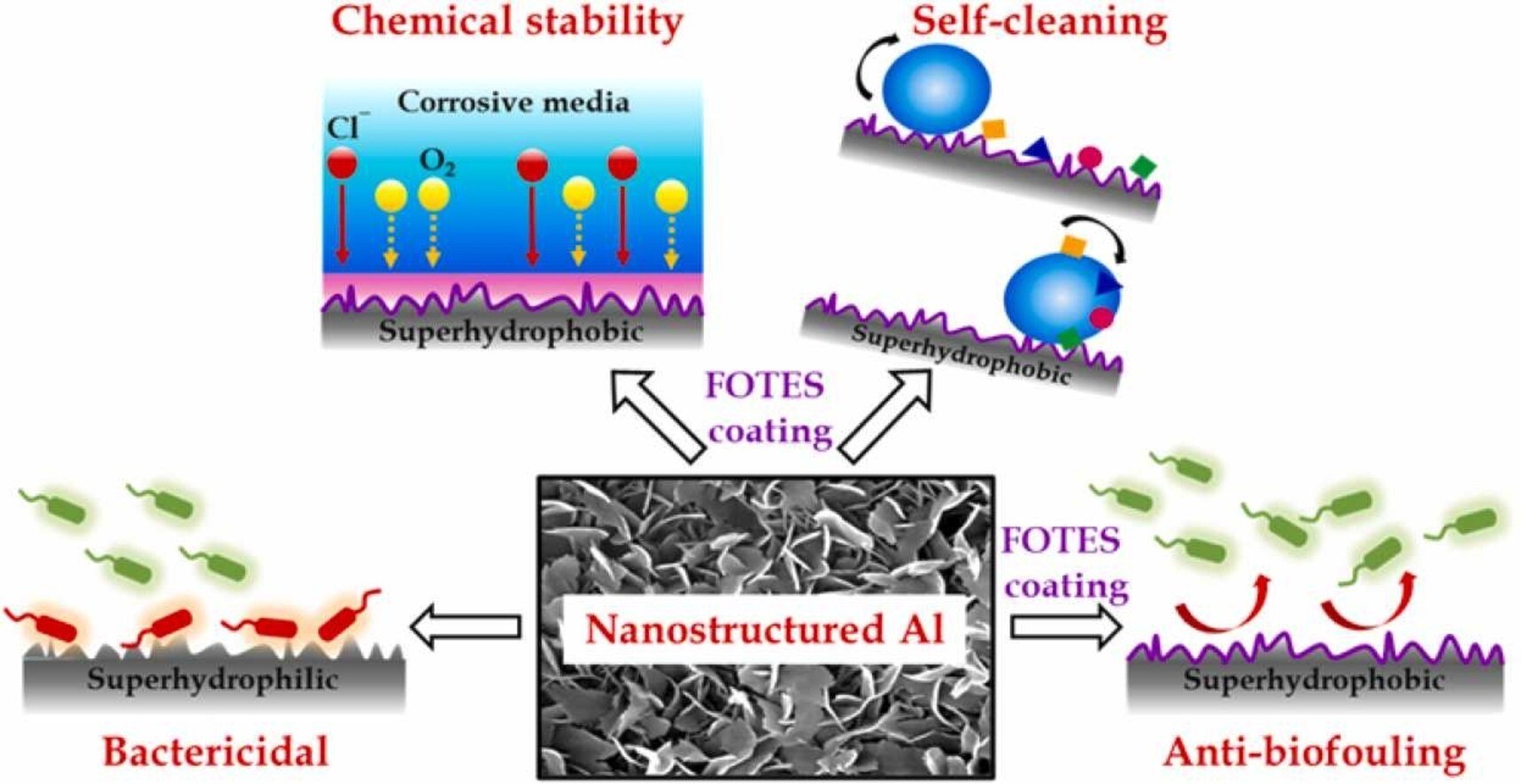

Led by Harpreet S. Grewal, the researchers achieved these properties by engineering micro- and nanostructures on aluminium through a cost-effective and environmentally friendly fabrication method. The process involved imprinting aluminium sheets with micro-patterns, followed by immersion in hot water, leading to the formation of two distinct surface types: "Nano" and "Hierarchy." To further reduce surface energy and boost water-repellent properties, both surfaces were coated with a fluorinated silane compound.

Tests revealed that, depending on the treatment, the modified surfaces could exhibit either superhydrophobic (extremely water-repellent) or superhydrophilic (highly water-attracting) properties. For instance, the "Nano" surface achieved a contact angle of 163 degrees, allowing water droplets to roll off effortlessly. These features are especially valuable in environments where maintaining cleanliness or minimising moisture is essential.

The team carried out some tests to understand the behaviour of aluminium under different situations, they are:

"The dense nanoflakes function like a bed of spikes," Grewal explained, describing how the surface physically disrupts and penetrates bacterial cells, effectively reducing biofilm formation without relying on chemical disinfectants. Importantly, the fabrication process is free from hazardous chemicals and engineered for scalability, making it suitable for industrial applications.

In addition to marine and food industries, these surfaces could be tailored for use in biomedical devices, electronics, or packaging materials, where maintaining contamination-free conditions is essential. The research was supported by the Council of Scientific and Industrial Research (CSIR), India. Moving forward, the team plans to focus on evaluating the surfaces' durability in real-world conditions and scaling up the fabrication process for potential commercial applications.

Information source: TOI

Image Source: Colloids and Surfaces B: Biointerfaces

Responses