On Tuesday, April 18, the leading mobility technology company Magna and the Department of Energy Pacific Northwest National Laboratory (PNNL) unveiled a new manufacturing process which saves 50 per cent of energy and cuts CO2 emissions by nearly 90 per cent.

The Shear Assisted Processing and Extrusion (ShAPE) gathers aluminium scraps and cuttings left over from automobile production and convert them into new vehicle components. By using this method, less raw aluminium ore needs to be mined. The team is now redesigning this procedure to create lightweight electric car parts.

Magna and the PNNL have been working together on the study for four years, with funding provided by the Lightweight Materials Consortium (LightMAT) Programme of the DOE's Vehicle Technologies Office. ShAPE has excellent mechanical qualities, and the study is optimistic that one day it will be able to produce parts for the construction and aerospace sectors as well.

"We showed that aluminum parts formed with the ShAPE process meet automotive industry standards for strength and energy absorption. The key is that ShAPE process breaks up metal impurities in the scrap without requiring an energy-intensive heat treatment step. This alone saves considerable time and introduces new efficiencies," said Scott Whalen, a PNNL materials scientist and lead researcher.

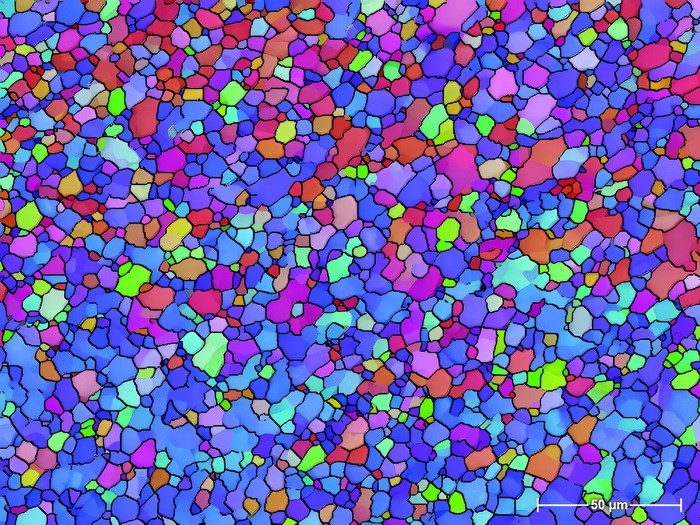

This study extrudes an industrial waste aluminium alloy 6063 into circular, square, trapezoidal, and two-cell trapezoidal profiles using a rotating ShAPE process incorporating a porthole die design. A trapezoidal profile with an average grain size of 6.7 m in the as-extruded state is given microstructural characterisation. Round tubes outperformed industry requirements for yield strength (246.9 10.4 MPa), maximum tensile strength (270.8 9.6 MPa), and consistent elongation (16.5 2.4%).

The most recent development does away with the requirement to add freshly mined aluminium to the material before utilising it for new components, as detailed in a new paper and a research article in Manufacturing Letters. Aluminium component makers can lower the price overall and more effectively replace steel by reducing the cost of recycling aluminium.

Responses