On 13th March 2021, the self-taught British designer Tom Dixon will unveil on a digital platform, the new and innovative chair at his Studio '24 hours in Milan'.

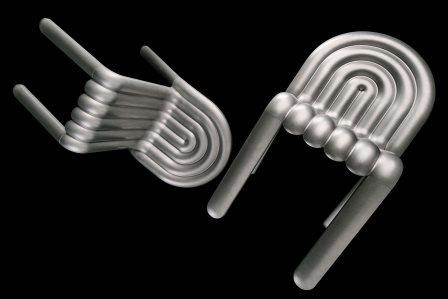

The chair made of recyclable aluminium is named as ‘HYDRO Chair’ and is designed for longevity, multiuse and importantly for easy recycling. As it is manufactured with 100% aluminium and with few components, it is effortless to take apart when sometime in the future it will reach the end of its life as a chair.

Tom Dixon is renowned for his love of metals and chose aluminium due to its endless design opportunities like light and robust and the chair is designed keeping sustainability in mind.

Tom Dixon, Founder and Creative Director of Tom Dixon Studio, said: “I have always been obsessed with materials and aluminium in particular. It's a metal I find incredibly interesting with its endless opportunities in terms of shapes and surface qualities. Being able to work with the top aluminium and material experts in the industry was an opportunity I couldn't refuse.”

Aluminium remains one of the few materials that can be recycled endlessly without losing its properties and is, therefore, an ideal material for a circular economy, getting more for less.

Hilde Kallevig, Head, Brand and Marketing in Hydro: “The future needs circular materials and we need to design products that live longer, can be recycled or reused. Understanding material properties and manufacturing processes will help create more sustainable products designed with recycling or reuse in mind, and that is why we believe it is important for designers and manufacturers to collaborate.”

In late 2018, Hydro's technical experts and the Dixon team first met, the challenge was the design, which has to shape a metal chair seat in one singular piece. However, it was not an easy task and sought extensive research into various technologies and production had to balance cost, design, practicality and technical feasibility.

With experts from Hydro and the Dixon team working closely together exchanging ideas, they were able to push technology forward, which resulted an innovation in aluminium technology, The HYDRO Chair is produced by using superplastic forming of aluminium alloys that were originally developed for the automotive industry. The ballooned pattern has been achieved by blow-forming the metal (superplastic forming) at high temperatures and then laser cut by robots.

These methods were developed in the automotive industries to make deep and complex forms that only a few years ago were impossible to achieve.

The aluminium can be stretched to several times its original size without failure when heated.

By tapping into Hydro's aluminium expertise and using the 5000 series of specially developed superplastic alloys, the chair is lightweight but robust and made to last, also outdoors.

A limited first edition of the chair will be sold exclusively on Tom Dixon's online store at £2,021 each around the world and to selected international partners from April 13.

Responses