Sandvik Coromant, a prominent metal cutting expert, has introduced the M5F90 face-milling cutter, specifically designed to process thin-wall aluminium components without burring, scratching, or chipping due to its smaller cutter body and brazed Polycrystalline Diamond (PCD) tips. This cutting-edge technology, designed exclusively for making aluminium battery racks, is poised to revolutionise the production process for automotive original equipment manufacturers (OEMs) and help them remain ahead in a competitive market.

The automotive sector is seeing a rise in OEM engagement in battery cell manufacture, which is now physically closer to car assembly factories. As battery technology, durability, and performance become increasingly essential differentiators for OEMs, efficient machining solutions are more critical than ever. According to Fernando Oliveira, Global Manager for Automotive Aluminium at Sandvik Coromant, the M5F90 face-milling cutter may help OEMs succeed in these areas.

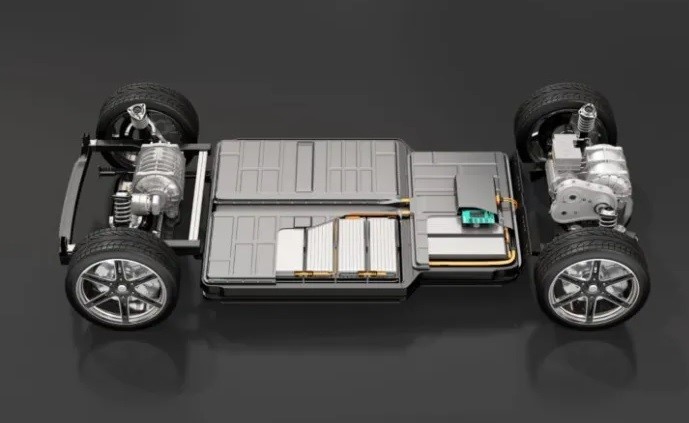

Battery systems are continually developing, necessitating the manufacture of near-net-shaped components based on more sophisticated designs. Machining these complicated patterns requires lightweight tools that reduce machine tool impact while ensuring the component keeps its form.

OEMs are investing more in battery manufacturing and racing to develop lighter, more efficient electric cars (EVs) with longer ranges per charge. The term "lightweight" has arisen as a tactic for improving fuel economy and handling. Aluminium, one of the lightest metals, has become a well-established lightweight alternative in the automobile industry. It is an excellent option for battery racks because of its great strength, corrosion resistance, and recyclability.

Aluminium battery racks provide unique machining issues due to smaller faces with more threads, holes, and other characteristics. The M5F90 face-milling cutter is designed expressly to overcome these issues. The cutter's brazed PCD inserts enable fast feed rates, prevent cutting vibrations, and assure consistent performance with longer tool life. The M5F90 cutter was recently used to make an aluminium battery tray, demonstrating its capacity to do roughing and finishing in a single operation, reducing time and increasing production.

The car sector is concerned about lowering CO2 emissions. Lightweight techniques, such as using aluminium components, may help drastically reduce carbon emissions. With its capacity to quickly create lightweight aluminium battery racks, Sandvik Coromant's M5F90 cutter corresponds with OEM sustainability policies and supports its efforts to manufacture environmentally friendly automobiles.

Responses