The development of numerically controlled machinery and the increasing prevalence of computers paved the way for the emergence of the first industrial robots. Griffith "Bill" P. Taylor is credited with creating the first industrial robot that adhered to the ISO definition in 1937. The robot featured was equipped with one electric motor and was assembled using Meccano components, resembling the appearance of a crane. Among its various movements, the robot had five axes, two facilitating gripping and rotation capabilities. Its automation system relied on paper tape, which had strategically placed holes punched in it. These holes served to power solenoids, enabling the robot to autonomously arrange wooden blocks in pre-defined patterns.

After the year 1980, there was a significant surge in robotics innovation, marked by remarkable advancements. In 1981, Takeo Kanade introduced a groundbreaking creation: the first robotic arm featuring joint-mounted motors. This innovative design exhibited superior speed and precision compared to its predecessors, setting a new standard in robotic technology.

Robotics represents an interdisciplinary field of engineering that integrates various disciplines to create, develop, program, and employ robotic machines. In contrast, automation refers to utilising computer software, machinery, or other technological means to perform tasks typically carried out by human workers. Within the realm of aluminium production, automation is employed throughout the entire value chain to ensure improved precision in product manufacturing. On the other hand, robotics finds application in specific industry sectors.

The aluminium industry actively embraces robots and automation to improve quality and productivity. As labour and material costs continue to rise, there is mounting pressure on the aluminium sector to enhance its efficiency. By exploring innovative avenues through robotics and automation technologies, businesses in the aluminium industry can unlock untapped potential for productivity gains, paving the way for novel and unexplored opportunities.

Over the years, the aluminium industry has been keen on enhancing its work efficiency and production capabilities. In pursuit of this goal, robotics emerged as a crucial player in creating automated systems that adapt to evolving demands.

However, in recent times, the utilization of robots in the aluminium manufacturing industry has seen a notable surge. These robots are crucial in various processes, including casting, extrusion, and machining. Their remarkable ability to execute repetitive tasks with precision, consistency, and speed has significantly enhanced productivity and effectively minimized labour costs.

One of the most significant advantages of employing robots in the aluminium sector is their capacity to handle hazardous materials and operate in potentially dangerous environments. By delegating these tasks to robots, human workers are shielded from potential harm, resulting in a considerably safer work environment.

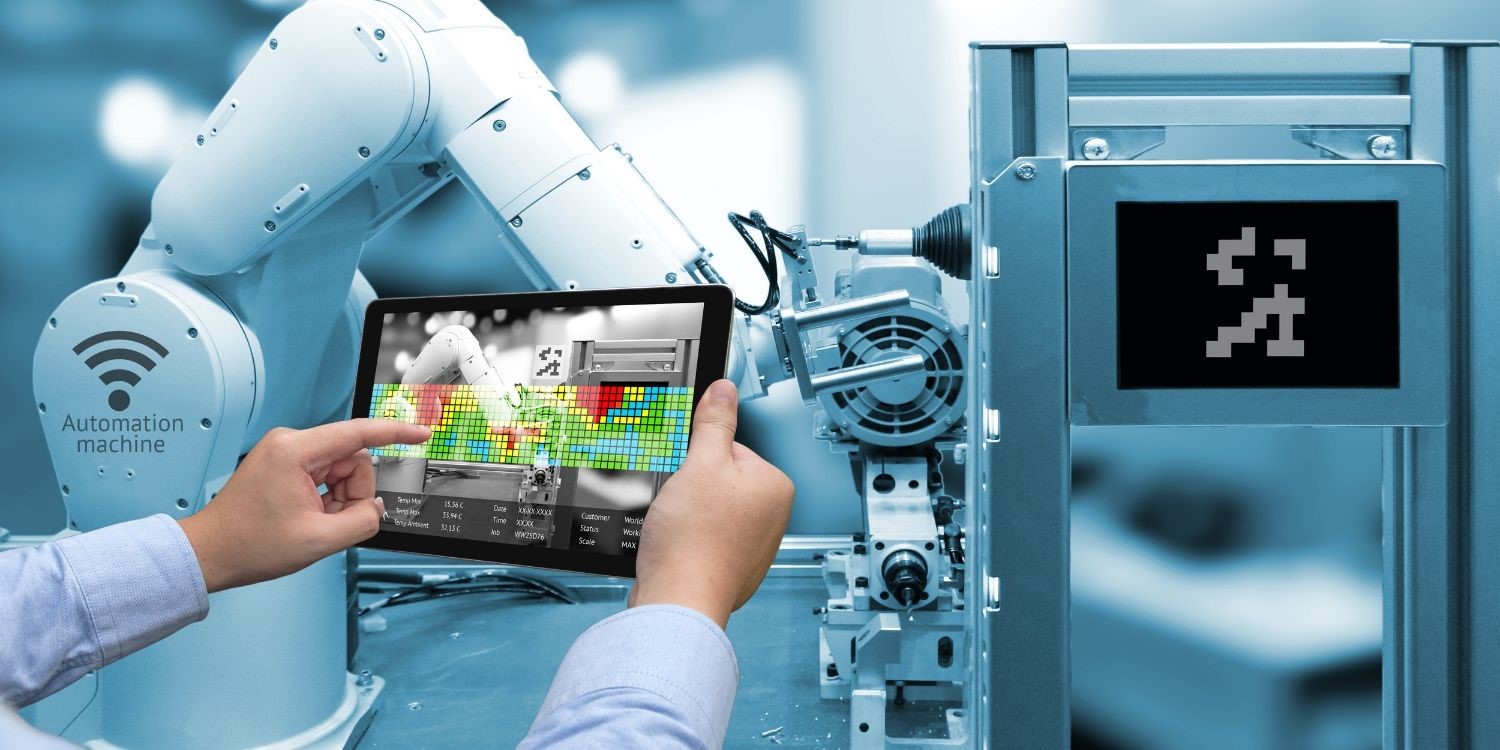

Robotics is pivotal in implementing Industry 4.0 principles in the aluminium sector. By integrating robotics with the Internet of Things (IoT) and data analytics, manufacturers can gain valuable insights, streamline processes, and make informed decisions based on data to enhance efficiency.

Responses