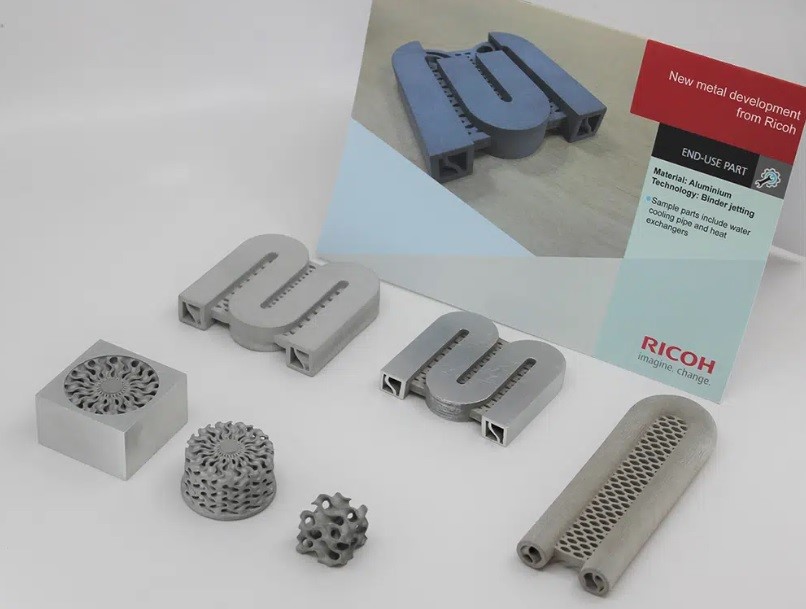

On November 7, Ricoh Company, Ltd. will increase the size of its Customer Experience Centre (CEC) in Telford, United Kingdom, to speed up co-creation with clients and partners in the manufacturing sector. These tools will be handy for those considering metal binder jetting (MBJ), specifically aluminium binder jetting, 3D printers for electric vehicles (EVs), electric aircraft, etc. As a result, new value can be created, for example, by improving the energy efficiency of electric components (e.g., motors and batteries).

Using aluminium, a difficult material to sinter is a focus of Ricoh's approach to binder jetting technology. By employing this tactic, Ricoh aims to join the metal binder jetting race, which has recently picked up steam with HP's formal release of its Metal Jet technology and first systems and Markforged's acquisition of Digital Metal, the pioneers of metal binder jetting. They will compete against industry leaders Desktop Metal (which includes ExOne) and GE Additive's still-under-construction H2 system.

“There are technical issues with many products where they cannot fully perform due to heat problems or limitation of weight reduction. We are confident that Ricoh’s unique aluminum BJ technology will significantly contribute to solving these issues our customers face. With the opening of the CEC, we would like to accelerate co-creation with our customers to realize additional value for customers’ clients,” said Tokutaro Fukushima, General Manager of Additive Manufacturing Business Center, Ricoh Futures BU, Ricoh Company, Ltd.

Co-creation activities will take place at this CEC, which will be created with a focus on additive manufacturing. Ricoh will educate consumers about the potential of its technology through demonstrations. Ricoh will also expand its knowledge of possible client pain spots through activities at CEC and make suggestions for solutions that might help customers realise the new value that goes above and beyond their expectations by offering 3D printers and a comprehensive production workflow solution.

Ricoh can make complicated aluminium parts that are difficult to make with current production techniques by employing 3D printers, resulting in lightweight parts, high-performance heat exchange parts, and other components. This would assist in resolving the cooling issue, which has emerged as significant difficulty in the electrification of various places. In addition to heat exchangers, 3D printers may be used for multiple things. With customers, Ricoh will investigate aluminium BJ technology applications.

The main aim of the company is to create more efficient production. One of the company's key issues is the "realisation of a zero-carbon society." With the help of Ricoh's 3D printers, customers may create extremely energy-efficient goods, creating a zero-carbon society. Ricoh intends to achieve zero GHG emissions throughout the whole value chain.

Responses