Ricoh 3D, headquartered in Telford, has announced plans to showcase its aluminium Binder Jetting (BJT) technology alongside its next-generation thermal management solutions at the upcoming Battery Cells & Systems Expo. Scheduled for July 9–10, 2025, the event will take place at the NEC, Birmingham, UK.

With sustainability now a driving force in product innovation, Ricoh 3D highlights the growing demand for low-carbon, energy-efficient technologies as businesses increasingly reassess how products are designed, manufactured, and managed across their entire lifecycle.

The rapid growth of electric vehicles (EVs) clearly illustrates this shift. As global mandates push for advanced battery packs, inverters, and electric motors, engineers face new challenges in managing the intense heat produced by increasingly compact, high-power systems.

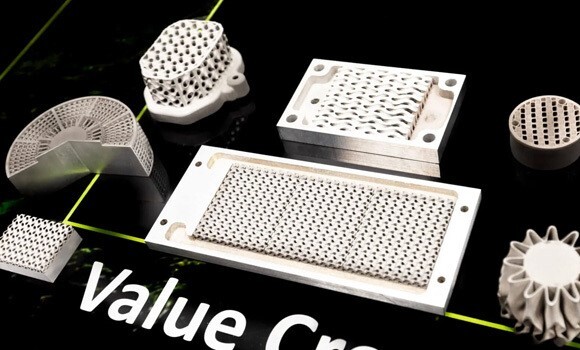

“Thermal management is no longer a secondary consideration – it is a critical design imperative. From automotive and aerospace to consumer electronics, energy storage, defence, and data centres, effective heat dissipation is fundamental to both performance and safety. Components such as heatsinks, cooling plates, and heat exchangers are now at the core of sustainable innovation,” said Ricoh 3D’s Head of Additive Manufacturing and Applications, Mark Dickin.

Binder Jetting (BJT) Additive Manufacturing offers a powerful solution by enabling the production of complex, lightweight, and thermally efficient components that are often unachievable with traditional methods. This technology allows manufacturers to minimise material waste, reduce component weight, and enhance energy efficiency without compromising structural integrity or performance.

These advantages align closely with broader global objectives, including achieving carbon neutrality, advancing circular manufacturing, and accelerating industrial electrification. The Battery Cells & Systems Expo 2025 is set to host over 300 exhibitors, welcome more than 5,500 attendees, and feature 150 expert speakers, delivering valuable insights into the latest battery trends, manufacturing innovations, safety developments, and sustainability efforts.

As electrification continues to transform sectors such as automotive, aerospace, energy, and electronics, effective thermal management emerges as a critical factor in ensuring performance, reliability, and energy efficiency across these applications.

Responses