Researchers at Rice University have developed a faster, cleaner method to recover aluminium and remove toxic metals from bauxite residue, commonly known as red mud. This hazardous by-product of aluminium production has long challenged the industry, but the new process offers a potential breakthrough in sustainable waste management.

Image Source: Rice University

Did you know that for every tonne of alumina produced, roughly 1.25 tonnes of this caustic residue are generated. And till date, more than 4 billion tonnes have accumulated worldwide, making red mud far more than a by-product.

But what is this red mud?

Red mud, also known as bauxite residue, is the by-product left after alumina is extracted from bauxite ore through the Bayer process. This highly alkaline, dense sludge is rich in oxides of iron, aluminium, titanium, sodium, and even traces of rare earth elements. Traditionally, it was stored in vast slurry ponds, a practice that has occasionally resulted in serious environmental consequences when containment systems failed. As global alumina production continues to climb in response to rising industrial demand, red mud volumes have grown at the same pace, creating serious environmental and management concerns. Its deep red colour stems primarily from iron oxides, along with traces of other oxides.

Get your hands on - A Comprehensive Analysis of Bauxite Residue - Red Mud

The method developed by Rice University researchers

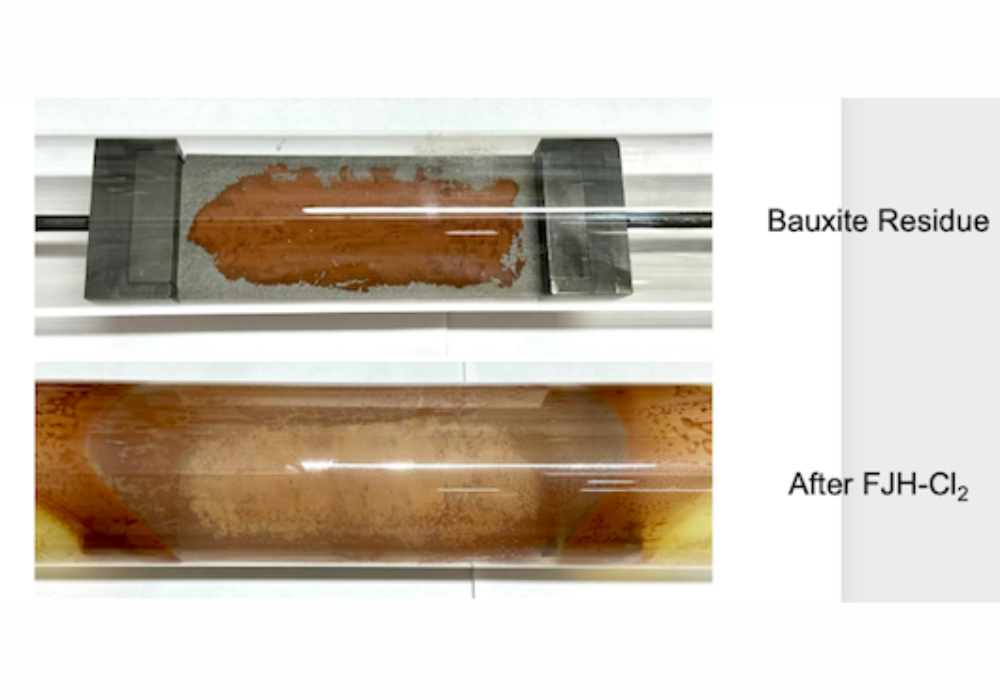

This is where the team of researchers from Rice University have come into the scenario. The method uses flash Joule heating (FJH), where a powerful electrical pulse passes through the material in under a minute. When combined with a small amount of chlorine gas, the process vaporises toxic metals, leaving behind an aluminium-rich residue ready for reuse. James Tour, professor of chemistry and materials science at Rice, described the breakthrough as a major industrial milestone.

“Our research presents a potential game-changing solution for the red mud crisis. This advance is massive from an industrial perspective, turning what was once a toxic liability into a valuable asset in under one minute. The speed and simplicity of this method set it apart,” Liu said. “In just 60 seconds, we extracted 96 per cent of the iron and nearly all the toxic species, while retaining almost all the aluminium,” said Qiming Liu.

The team showed that the purified aluminium can either re-enter the production cycle or be repurposed into durable ceramic tiles and bricks. Every year, millions of tonnes of red mud build up across the globe, posing risks of river contamination and catastrophic storage failures.

Conventional treatment methods typically require long heating cycles or harsh chemicals, both of which are expensive and damaging to the environment. Postdoctoral researcher and co-first author Qiming Liu emphasised that the new approach delivers efficiency without these drawbacks.

Also Read: Red mud generation trend across major countries, 2018 to 2023

The method eliminates the need for water or solvents and also strips away sodium salts, a crucial advancement. The outcome is a safer material, free from the caustic properties of untreated red mud.

Moving towards a sustainable industry solution

The researchers see potential for the method well beyond aluminium production. High-waste industries like steelmaking, mining, and rare earth processing could also leverage FJH to tackle their own massive residue streams. The technique delivers three key advantages -

For communities affected by red mud disasters, it offers a tangible path toward safer management. According to Tour, the work is advancing toward industrial deployment through Flash Metals USA, a Rice spinoff under Metallium Ltd., which is collaborating with aluminium producers to scale the process worldwide.

“What was once an environmental threat can now be transformed into building materials,” said co-first author Shichen Xu. “We have turned cleaned red mud into ceramics that are super hard, making them suitable for construction and aluminium recovery.”

The findings, published on September 15 in ACS Applied Materials & Interfaces, were the result of contributions from Rice researchers and partners at the US Army Engineer Research and Development Centre. The project received funding from the Air Force Office of Scientific Research and the US Army Corps of Engineers.

Responses