REM Surface Engineering has set up a fresh collaboration that centres on improving polishing techniques. The company has signed a Memorandum of Understanding with Germany-based Nikon Advanced Manufacturing (Nikon AM) Inc. and aluminium producer Constellium. Under this agreement, the three firms plan to refine finishing methods for Constellium’s Aheadd CP1 aluminium alloy, which is intended for use in laser powder bed fusion (LPBF) systems.

The agreement also brings the three organisations together to refine REM’s chemical polishing and chemical-mechanical polishing methods for PBF-LB components made from Aheadd CP1. By strengthening the post processing stage, the collaboration aims to accelerate the alloy’s adoption in demanding areas such as aerospace structures, RF waveguides and heat exchangers, while helping manufacturers reduce production time and costs.

Dr Behrang Poorganji, Vice President of Technology at Nikon AM, said the partnership formalises ongoing work to expand the alloy’s commercial potential. He noted the company aims to unlock its full application range, especially for thermal management and structural parts. A photograph shared by Nikon shows representatives from REM Surface Engineering, Nikon Advanced Manufacturing and Constellium marking the agreement.

Also read: Multiple constraints in play: Secondary aluminium alloy operating rate to slide in December

Aheadd CP1 has already attracted interest from industries including aerospace, defence, motorsport and semiconductors, owing to its strong material characteristics, ease of printing and single-step heat treatment. Nikon AM has been supporting industrial users as demand continues to grow. While many components perform well in their as-printed state, applications requiring greater fatigue resistance, cleaner fluid pathways, optimised RF performance or lower pressure drop often benefit from more advanced finishing. REM’s expertise in tailored surface treatments for metal AM will be central to developing new workflows suited to these high-performance uses.

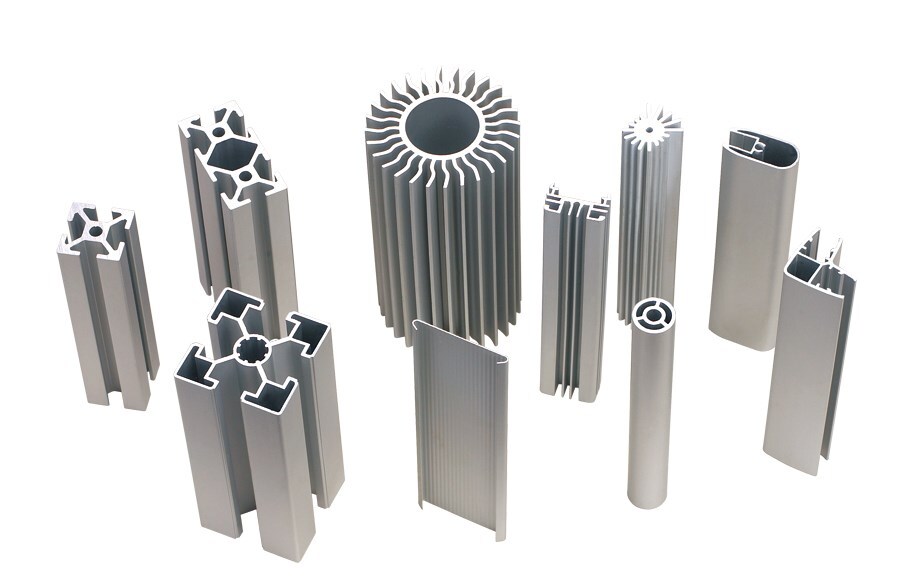

Sylvain Henry, Constellium’s Vice President of Research & Development, said the alloy continues to reveal strong potential and expressed enthusiasm for evaluating the new process innovations alongside Nikon and REM. Nikon also released an image displaying Constellium’s Aheadd CP1 alloy.

Don't miss out- Buyers are looking for your products on our B2B platform

The MoU follows a series of similar agreements across the additive manufacturing sector. In Australia, Aurora Labs Limited has signed an MoU with defence manufacturer Ares Armaments Australia Pty to advance design and rapid-production techniques for small-arms ammunition and components using exotic metals. It will further assess whether Aurora Labs’ RMP1 metal AM process, paired with Ares’ production expertise, could enhance manufacturing capabilities and produce components with greater strength, reduced weight and improved consistency.

Initial efforts will centre on small components to improve performance, cost-efficiency and regulatory compliance, with prototyping, production and testing scheduled for Q1 CY26 at Ares’ South Australian facilities.

Another partnership has taken shape in Australia, this time between ASC, the country’s sovereign submarine builder, and shipbuilder Austal. Announced during the 2025 Indo-Pacific International Maritime Exposition in Sydney, the agreement outlines plans to advance additive manufacturing technologies and to strengthen the skills needed to support them. The two organisations intend to reinforce Australia’s domestic supply chain for components used in Collins Class and Virginia Class submarines, while also introducing training programmes to help workers develop expertise in advanced manufacturing.

Explore- Most accurate data to drive business decisions with 50+ reports across the value chain

Responses